32DF9T02.B

3 - 8

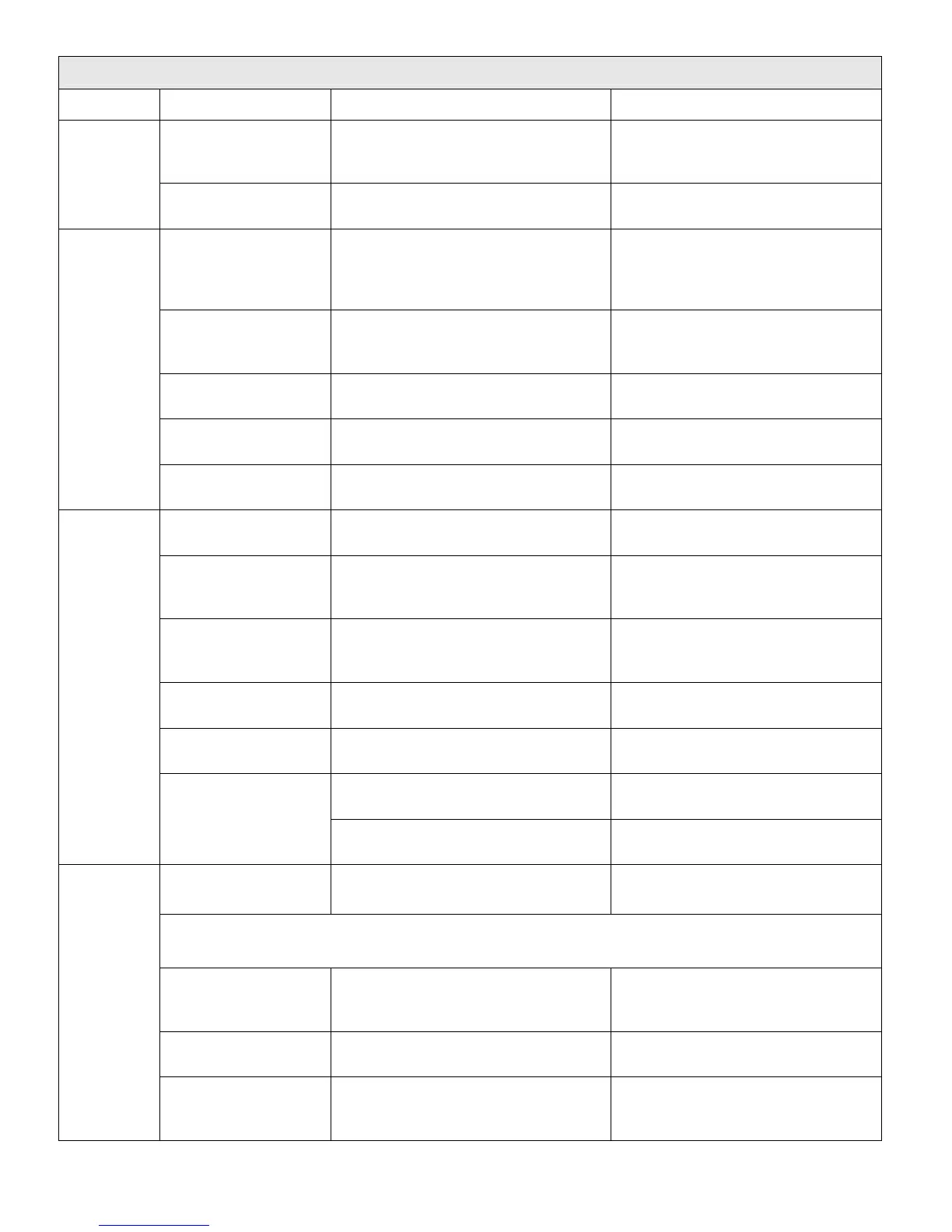

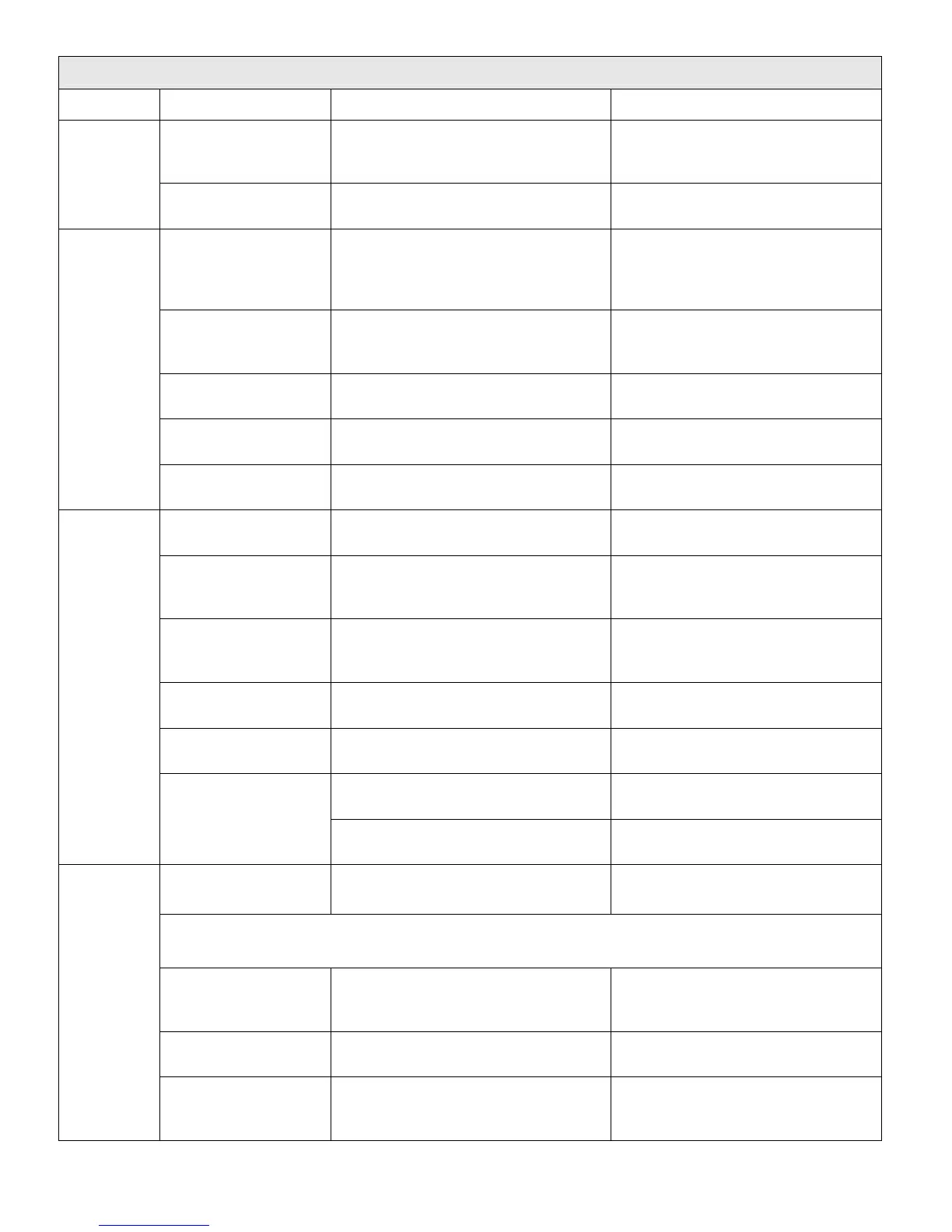

TABLE 3-1: WHEELCHAIR AND STANDEE LIFT TROUBLESHOOTING CHART

SYMPTOM PROBABLE CAUSE TESTS AND CHECKS CORRECTIVE ACTION

Down valve failure. Check for 24 vdc at terminal 4 on TS1

(located in pump enclosure).

If voltage is not present, replace

down valve (or replace entire

hydraulic pump assembly).

Debris in hydraulic

system.

Look for fluid returning to pump reser-

voir after button is released.

If fluid is seen, flush hydraulic system.

“Deployed” indicator

switch misadjusted.

Check for 24 vdc at pin 5 of P5. If voltage is not present, verify ad-

justment (switch is located at right

rear of carriage, with its plunger pro-

truding through right side).

Connector for rollstop

switches is loose.

Check for 24 vdc at pin 5 of J6. Verify secure connection of P6 and

J6 (connector is behind left rollstop

cover; Fig 3-3 in chapter 4).

“Up-Down” switch (on

control panel) failure.

Check for 24 vdc at pin 3 of P1 with

“Up” button pressed.

If voltage is not present, replace

switch (section F-1 of chap 3).

“Rollstop Closed”

switch failure.

Check for 24 vdc at pin 13 of P5. If voltage is not present, replace

switch (section F-1 of chap 4).

Rollstop

does not

close when

“Up” button

is pressed.

Rollstop motor failure. Check for 24 vdc between pins A and

B of J7.

If voltage is present, replace rollstop

motor.

A load of 75 lbs, or

greater, is on platform.

Check for presence of an object on

platform.

Remove object.

Main harness connec-

tor on controller is

loose.

Check for 24 vdc at pin 2 of P5. Verify secure connection of P2 to

controller.

Carriage-platform har-

ness connector on con-

troller is loose.

Check for 24 vdc at pin 2 of P5. Verify secure connection of P5 to

controller.

“In-Out” switch failure

(on control panel).

Verify 24 vdc at pin 2 of P1. If voltage is not present, replace “In-

Out” switch (section F-1 of chap 4).

In/Out motor failure. Check for 24 vdc across In/Out motor

(motor moves carriage).

If voltage is present, replace In/Out

motor.

Check for 24 vdc at pin 2 of P2 with

“In” button pressed.

If voltage is present, replace control-

ler.

Platform

does not

stow when

“In” button

and Stow

Guard but-

tons are

pressed.

Controller

failure.

Check for 24 vdc between pins 10 &

15 of P5 with “In” button pressed.

If voltage is not present, replace con-

troller.

Hydraulic manual

release valve is open.

Look for fluid returning to pump reser-

voir while pumping.

Close manual release valve; do not

over-tighten.

CAUTION

Verify 24 vdc power to lift is off before opening this hydraulic line. Support platform if deployed.

Manual backup pump

failure.

Loosen the fitting on hydraulic line that

is connected to pump assembly, and

then operate backup pump.

If fluid does not flow, replace manual

backup pump (or replace entire hy-

draulic pump assembly).

Hydraulic hose or

fitting leak.

Check for an oil accumulation in bot-

tom of enclosure, or in pump box.

Tighten hydraulic fitting or replace

hydraulic hose.

Manual

backup

pump does

not raise

platform.

Down valve is open. Remove down valve (part of hydraulic

pump assembly) and check for internal

debris or damage.

Clean or replace down valve (or en-

tire hydraulic pump assembly).

Loading...

Loading...