32DF9T02.C

4 - 21

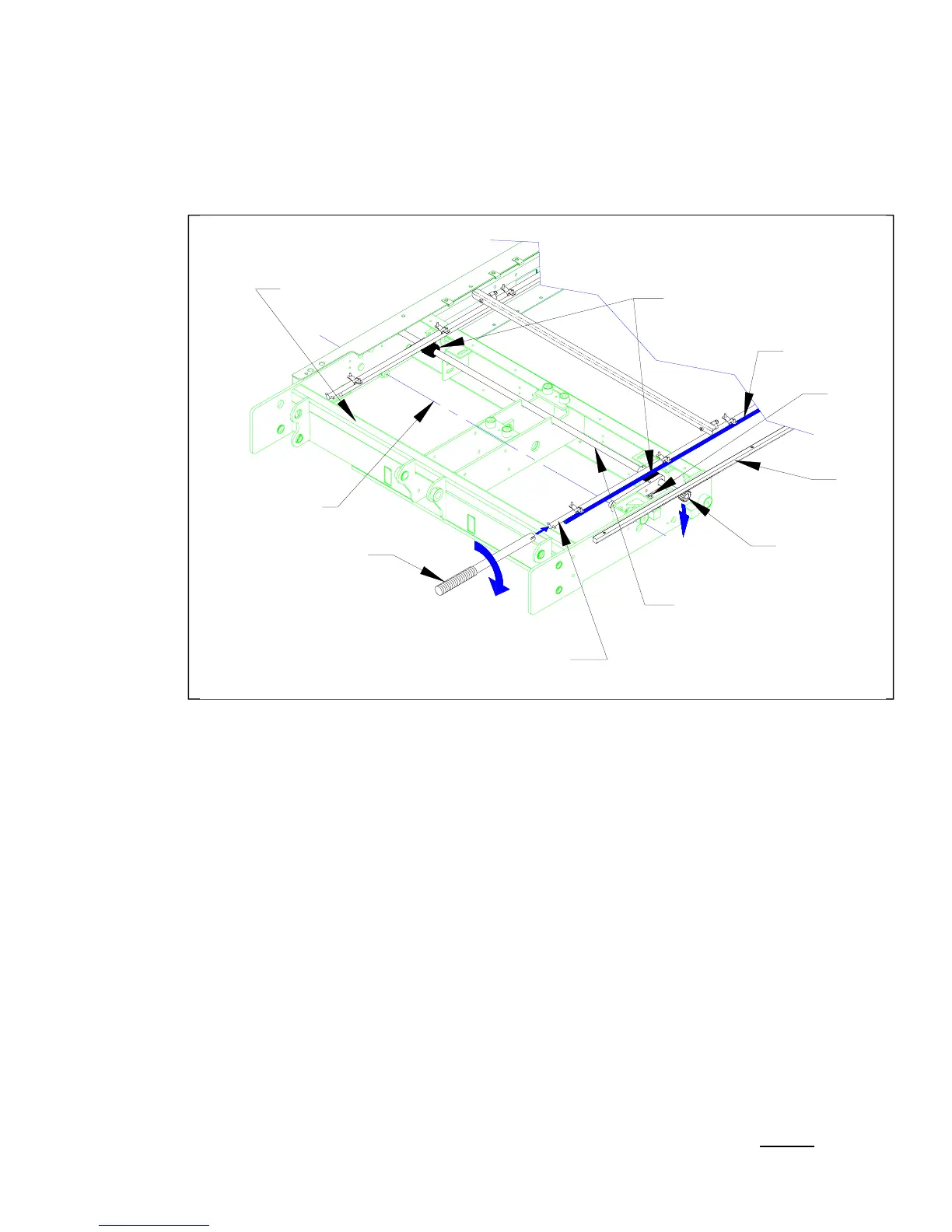

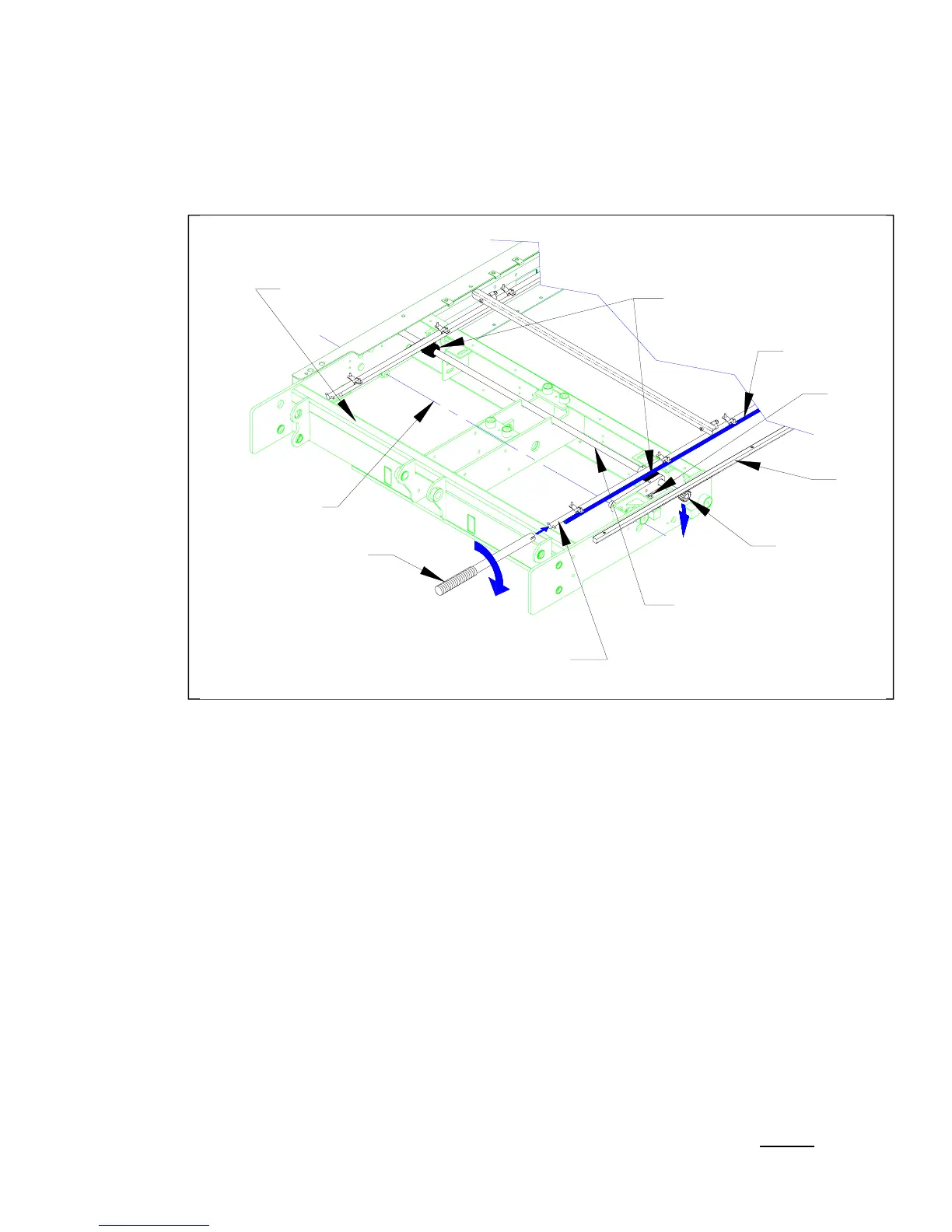

5. MANUAL PLATFORM RELEASE MECHANISM

Refer to Figure 4-20. The travelling frame (carriage, lifting frame, and platform) can be manually dis-

engaged from the enclosure by rotating either platform release shaft. Each release shaft has an ec-

centric cam that bears against a roller on the driveshaft. Rotating a release shaft pushes the final

driveshaft downward (against the force of an engagement spring), disengaging each driveshaft pinion

gear from its gear rack (mounted to the inside of the enclosure). Once the deployment system is dis-

engaged, the travelling frame can be moved by hand. The deployment system will automatically re-

engage when the platform is moved to the opposite end of its travel (stow or deploy).

a. Reset Ramp Adjustment

Rotating a release shaft disengages the platform from the enclosure. The reset ramps re-engage

the deployment system when the platform is moved to the opposite end of its travel. There are

two reset ramps; each one is a small, white plastic block. One ramp re-engages platform when it

is fully deployed, the other when platform is fully stowed. Both ramps are located at the top, rear

of carriage, above the final driveshaft. The adjustment procedure is similar for both ramps.

CHECK:

1) Rotate either release shaft to disengage stowed platform, and then pull platform out to the

fully deployed position.

2) One of the reset ramps engages a pin on one release shaft and rotates the shaft about 90

o

when platform reaches full deployment. Verify that deployment system has re-engaged by

attempting to push platform inward.

3) Rotate either release shaft to disengage platform, and then push platform to the fully

stowed position.

4) The second reset ramp will engage a pin on the second release shaft and rotate that shaft

about 90

o

when platform reaches the fully stowed position. Verify that deployment system

has re-engaged by attempting to pull platform outward.

ADJUST:

5) If either ramp fails to rotate its release shaft properly, the ramp position must be re-

adjusted. Loosen the two screws holding ramp in place, and slide ramp towards

pin about

1/8 inch. Tighten screws and repeat appropriate test (stow or deploy) to verify that deploy-

ment system has re-engaged. Repeat adjustment, if necessary.

ROLLERS

CAM

GEAR

FINAL DRIVESHAFT

DRIVESHAFT

PIVOT AXIS

PLATFORM RELEASE

SHAFT

MANUAL PUMP HANDLE

SPRING

PINION

RACK

GEAR

CARRIAGE

FIGURE 4-20: PLATFORM RELEASE COMPONENTS

Loading...

Loading...