32DF9T02.C

4 - 13

i. Disconnect main electrical harness connector from electronic controller.

j. Position a support stand in front of enclosure to place carriage on.

WARNING!

THE CARRIAGE ASSEMBLY IS HEAVY AND REQUIRES TWO PEOPLE TO REMOVE.

k. Pull carriage out of enclosure, supporting each side, and place on support stand.

NOTE: Care is required while extracting carriage to avoid damage. Watch for possible points of inter-

ference, such as the pins on the release shafts catching on the release reset ramps.

l.

Carriage Re-installation

Perform re-installation by reversing removal steps, with the following considerations. Pull hy-

draulic hose and electrical harness down through service access opening

before inserting car-

riage into enclosure. Route hose and cable back into installed carriage in their original positions.

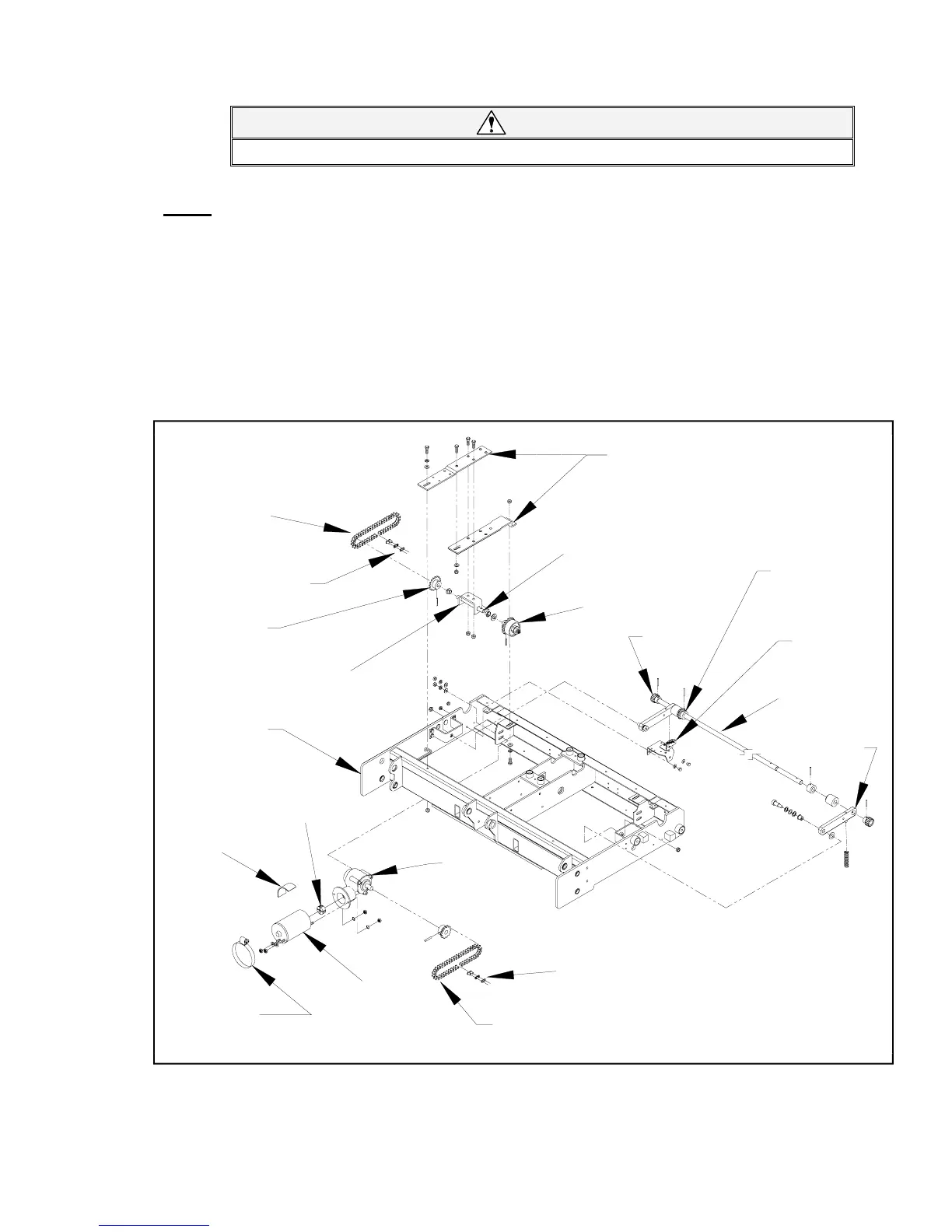

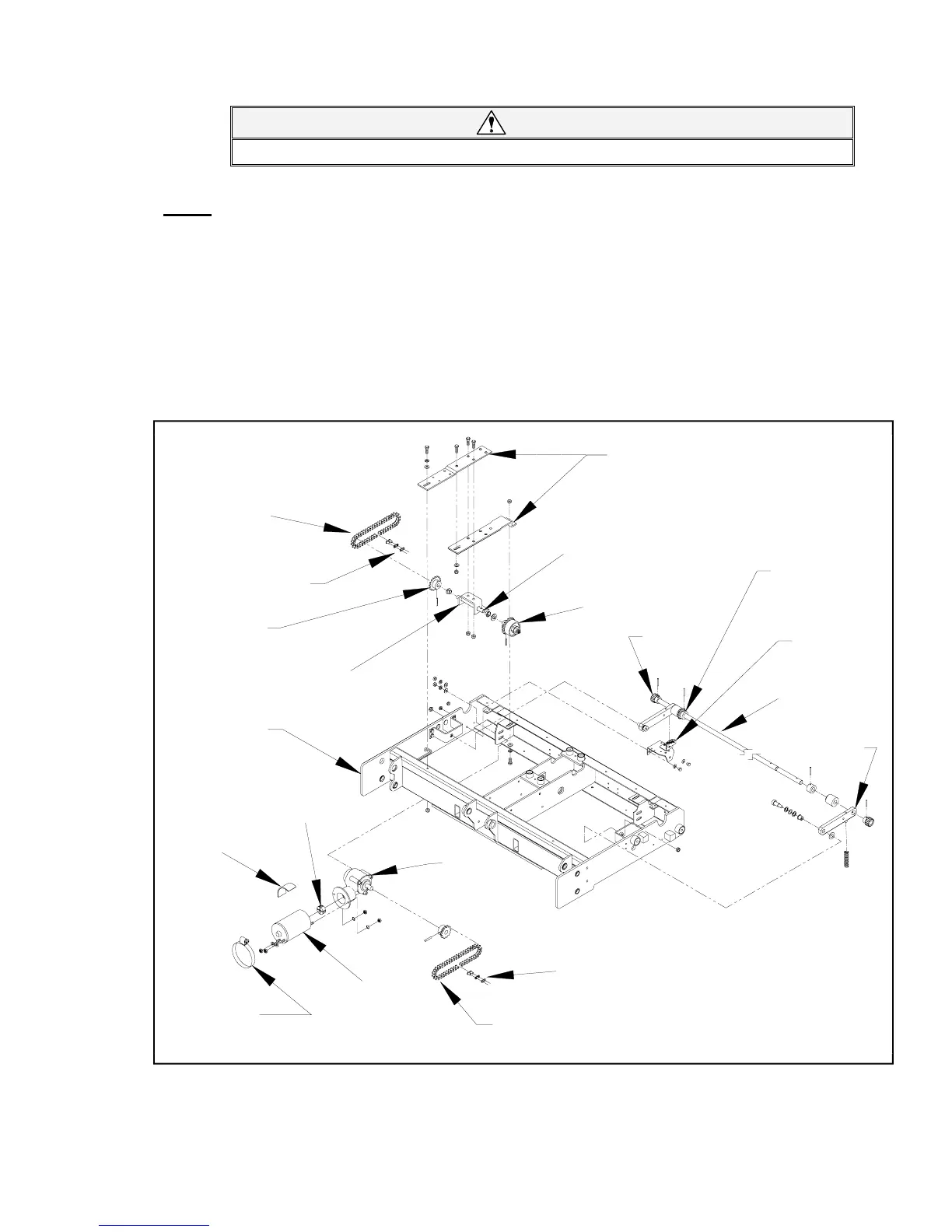

D. DEPLOYMENT SYSTEM

Refer to Figure 4-17. The deployment system propels the traveling frame (carriage, lifting frame, and plat-

form) out of enclosure, or pulls it back in. This section describes major deployment system components, in-

cluding how they operate, how to remove and replace them, and how to perform adjustments.

FIGURE 4-17: DEPLOYMENT SYSTEM COMPONENTS

INTERMEDIATE

SHAFT

TORQUE

LIMITING

CLUTCH

FINAL

DRIVESHAFT

PINION

GEAR

MASTER

LINK

PRIMARY

DRIVE

CHAIN

IN/OUT MOTOR

RUBBER

COUPLER

RUBBER

ISOLATION

GASKET

INTERMEDIATE

SHAFT

SUPPORT

MASTER

LINK

FINAL

DRIVE

CHAIN

GEARBOX

INTERMEDIATE

SHAFT

BRACKETS

MOTOR

RETAINING

CLAMP

SUPPORT

ARM

PLATFORM

RELEASE

SWITCH

CARRIAGE

DRIVESHAFT

SPROCKET

INTERMEDIATE

SHAFT SPROCKET

Loading...

Loading...