32DF9T02.C

2 - 7

i. Verify that bridgeplate is resting flat against floor. Adjust right-side rod-end so that shoulder bolt

can be installed without altering bridgeplate position. Install spacer and shoulder bolt, then

tighten rod-end jam-nut.

j. Reconnect positive battery cable at vehicle battery compartment.

k. Remove platform support and operate lift to verify that bridgeplate deploys correctly. Readjust

actuator rod assemblies, if necessary.

4. PLATFORM STOW AND INTERMEDIATE HEIGHT ADJUSTMENTS

The height of platform prior to being pulled into enclosure is referred to as “stow height”. When this

height is properly set, the platform will easily enter enclosure without hanging-up. The stow height is

factory set and normally does not require resetting after lift installation, except when major lift

disassembly is done. However, if the vertical travel limit has been adjusted, then stow height must be

reprogrammed.

Most dedicated entry models have an additional platform position referred to as “intermediate height”.

This height is generally a few inches below floor height, and is also factory-set. The height may be

reprogrammed for specific applications, or after major repair work. Some dedicated entry models move

the platform from the ground directly to floor height, without an intermediate stop.

An optional programming switch kit is available to program the stow and intermediate heights into the

controller memory. It is Ricon part number 17885.

NOTE: The stow and intermediate height values are stored indefinitely in the controller memory. Programming

the controller will clear the present value and store a new value.

a. To Program Stow Height:

1) Deploy platform.

2) Use manual back-up pump in combination with manual pressure release valve to position

top the surface of the platform lifting arms at the same height as the top surface of carriage.

This alignment assures that platform can be pushed into enclosure without difficulty.

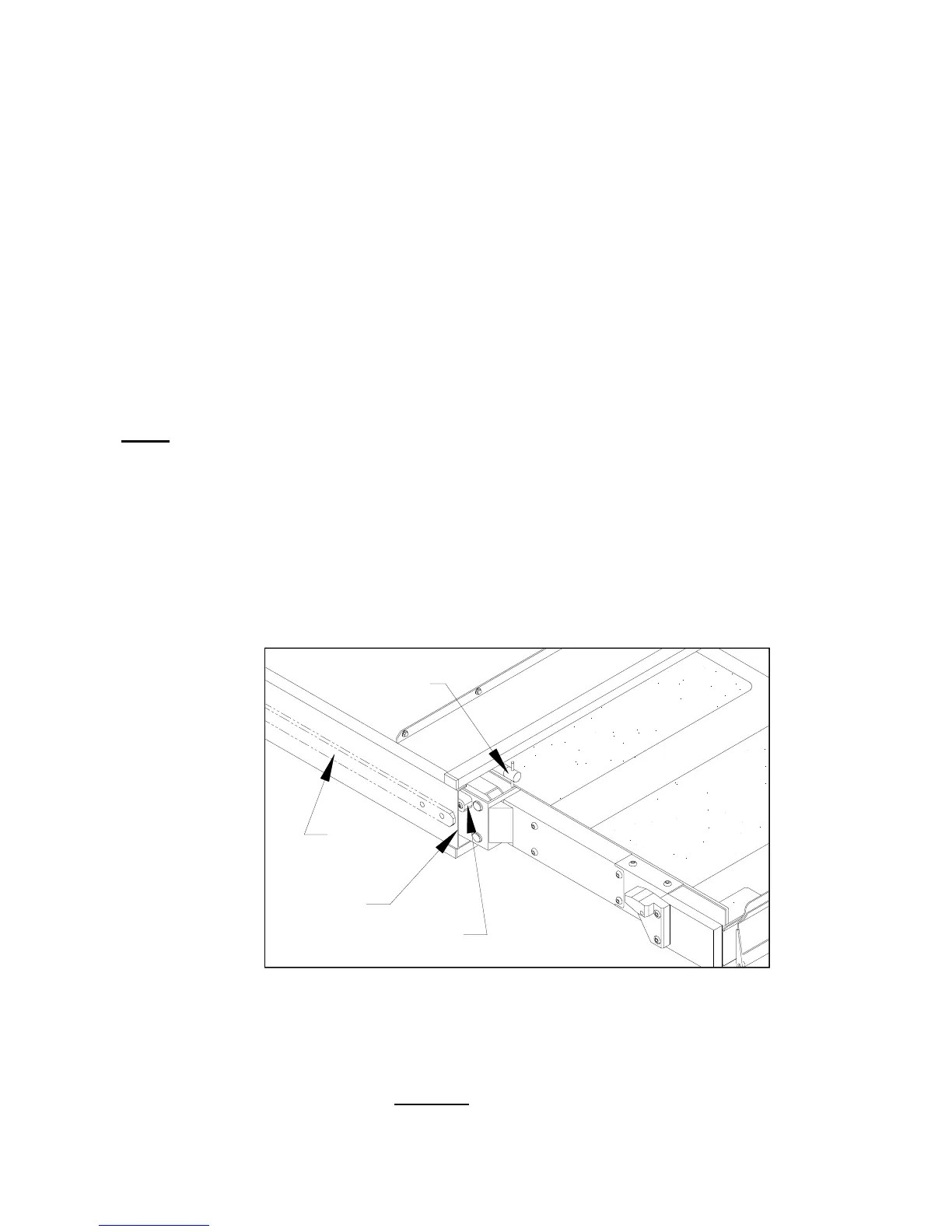

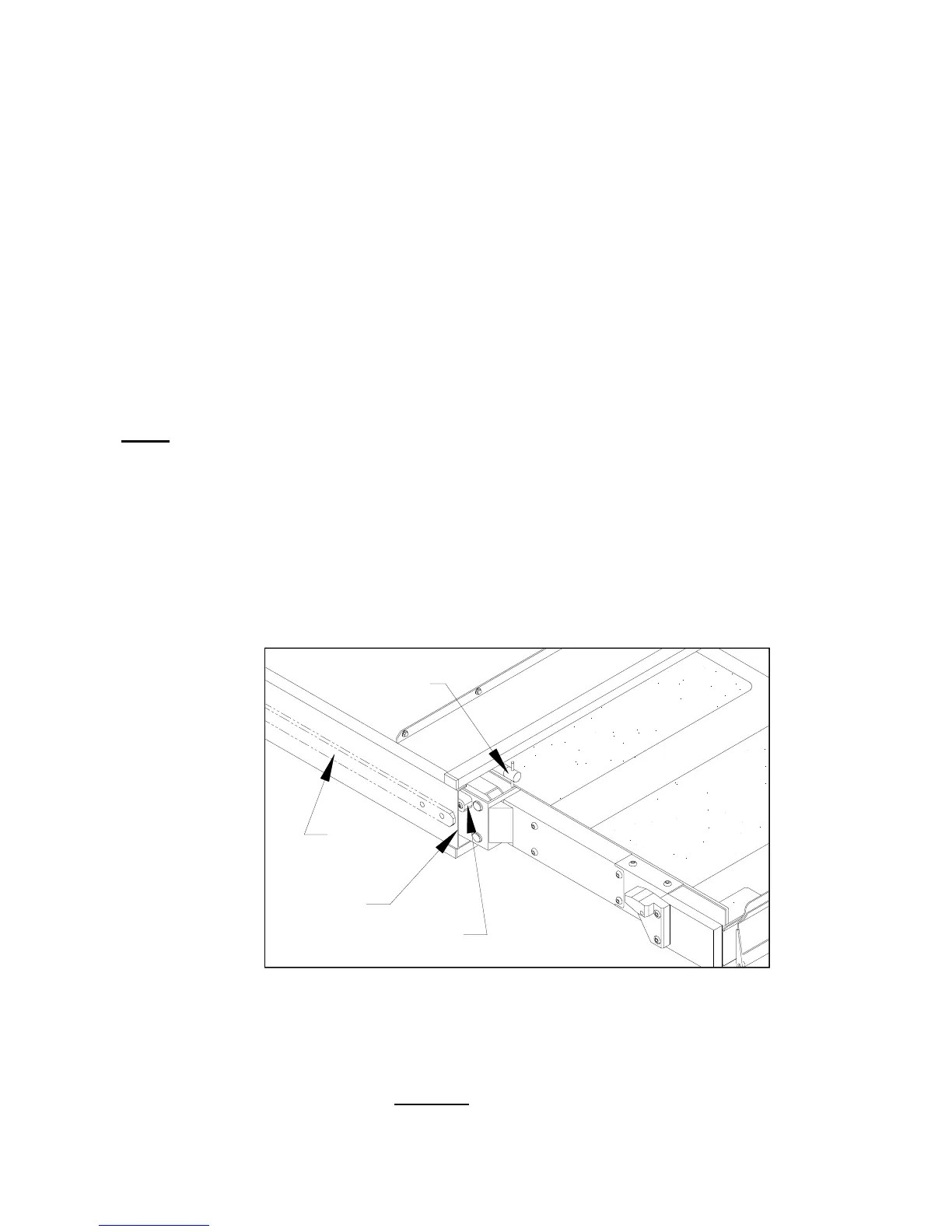

3) Refer to

Figure 2-4. Release manual platform lock, and then hand-push platform into

enclosure. Stop pushing when front face of white stow guide block (tear-drop shaped

plastic block) is adjacent to front edge of enclosure. The stow guide block will be visible

from front of lift.

4) Lower platform by opening manual pressure release valve (located on pump assembly),

and let stow guide blocks (left side and right side) settle on guide rails. Close valve.

5) Raise platform with manual back-up pump so that both left and right side stow guide blocks

are approximately 1/32 inch above guide rails.

6) Hand-pull platform completely

out of enclosure; the platform must lock in place to assure

accurate data entry. Check lock by attempting to push platform into enclosure; it must not

move.

FIGURE 2-4: STOW GUIDE BLOCK ALIGNMENT

GUIDE RAIL

(INSIDE)

STOW

GUIDE BLOCK

RELEASE

MANUAL PLATFORM

ENCLOSURE

Loading...

Loading...