32DF9T02.B

3 - 6

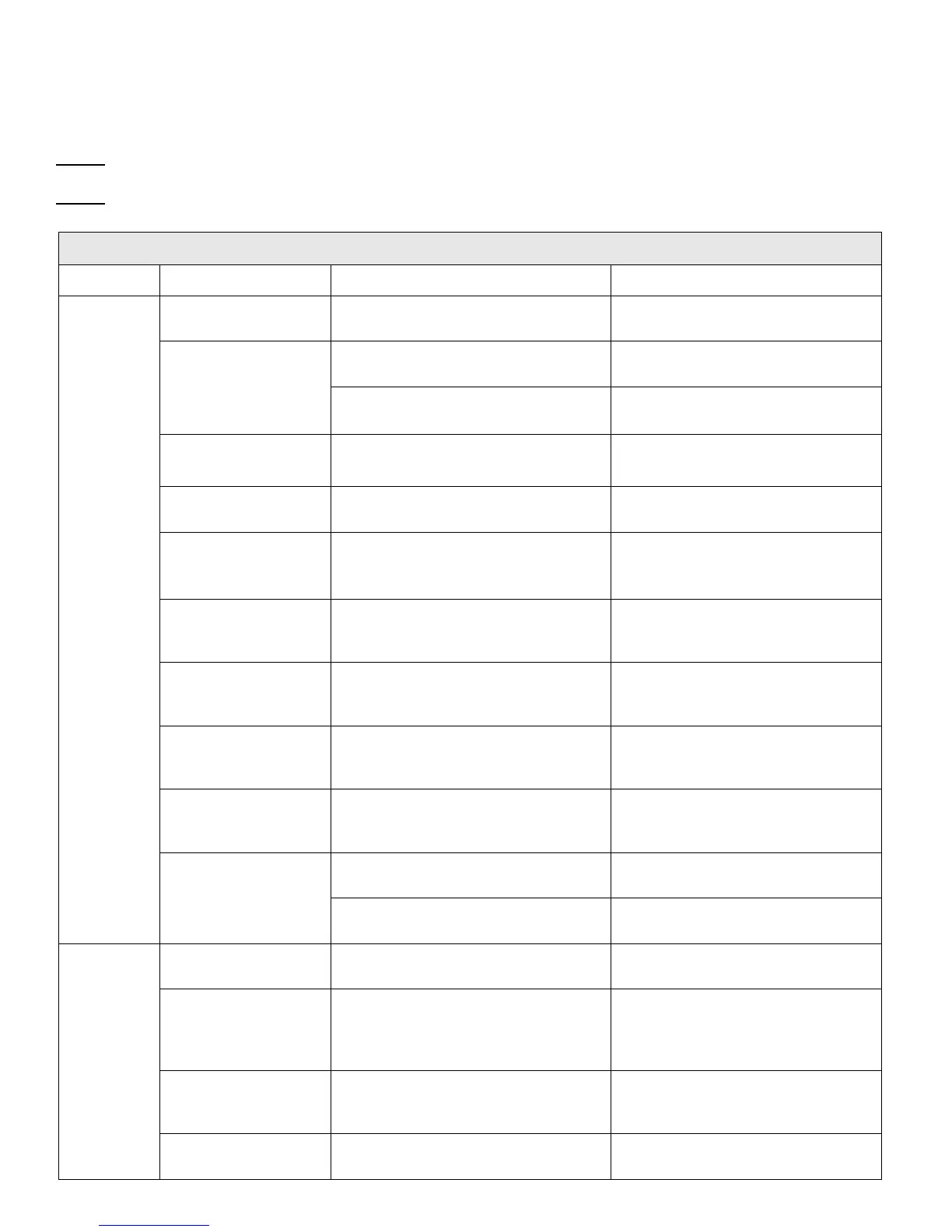

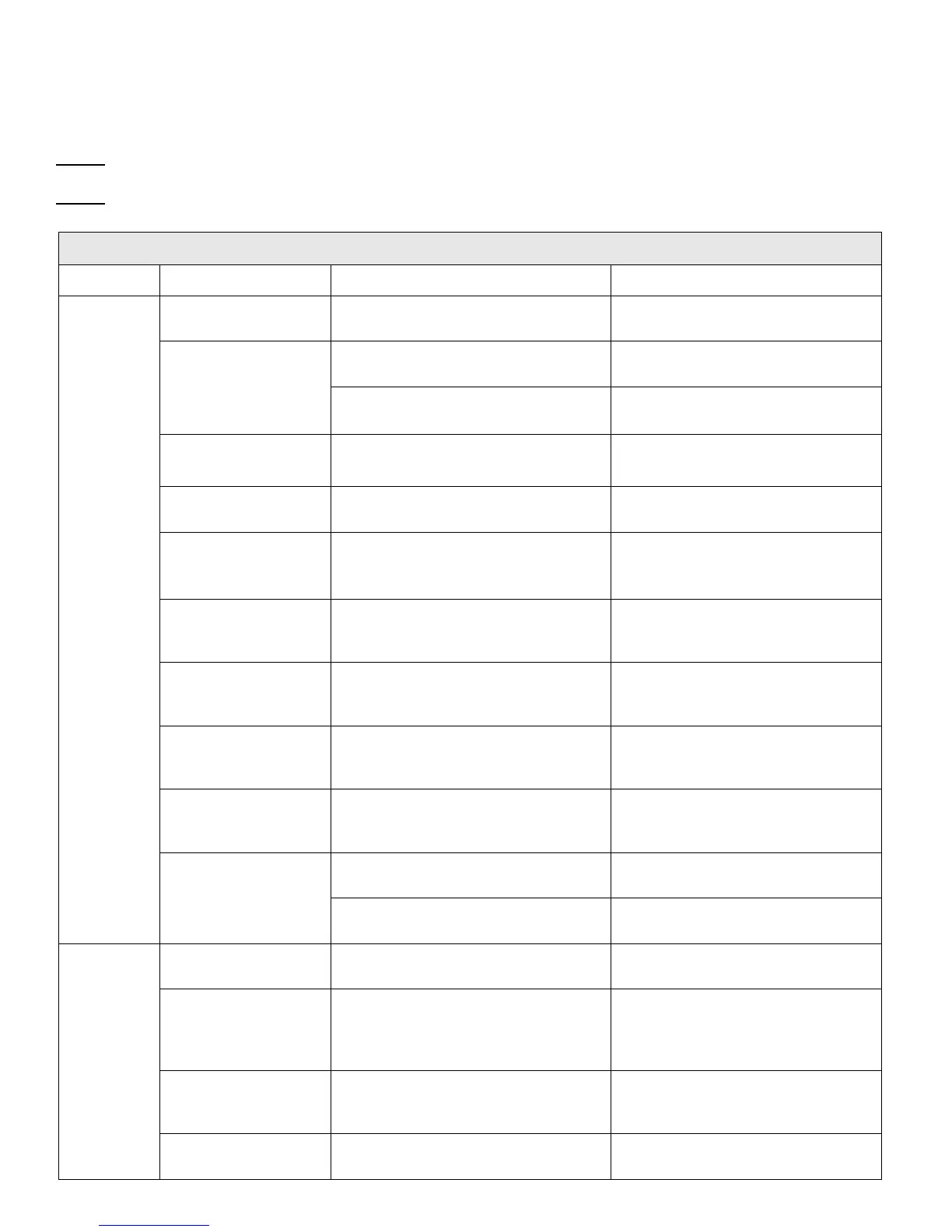

C. TROUBLESHOOTING CHART

Reference is made in the troubleshooting chart to connector pins located on harness connectors and components. Re-

fer to the Wheelchair Lift Electrical Wiring Diagram in Figures 2-11 and 2-12 for identification and location of these com-

ponents and connectors.

NOTE: Figures referenced in the troubleshooting chart are located either in this chapter or other chapters in this man-

ual.

NOTE: Verify that the 24 VDC power supplied to the wheelchair lift by the vehicle is present, and is capable of supply-

ing sufficient electrical current. Also, verify that vehicle interlock requirements are met.

TABLE 3-1: WHEELCHAIR AND STANDEE LIFT TROUBLESHOOTING CHART

SYMPTOM PROBABLE CAUSE TESTS AND CHECKS CORRECTIVE ACTION

24 vdc power is not

available to lift.

Check for 24 vdc at 50 A circuit

breaker.

Switch lift power on.

Check for 24 vdc from pin 7 on TS1 to

30 A circuit breaker (in pump box).

If voltage is not present, replace

power cut-off solenoid.

24 vdc power is not

present in lift.

1. Check for 24 vdc at pin 7 on P2.

2. Check 10A fuse at P2-1.

Replace fuse, if bad.

Lift 50 A circuit breaker

is tripped.

Check for 24 vdc at power cut-off sole-

noid.

Reset breaker.

Lift 30 A circuit breaker

is tripped.

Check for 24 vdc at pin 1 on TS1 (in

pump box).

Reset breaker.

Platform

does not

deploy.

Main harness connec-

tor on controller is

loose.

Check for 24 vdc at pin 1 of P2. Verify secure connection of P2 to

controller.

Carriage-platform

harness connector on

controller is loose.

Check for 24 vdc at pin 2 of P5. Verify secure connection of P5 to

controller.

Obstruction in

enclosure.

Look inside enclosure for foreign ob-

jects and check for twisting of main

harness.

Remove obstruction; check for re-

lated damage.

In/Out motor failure. Check for 24 vdc across In/Out motor

(moves carriage) with “Out” button

pressed.

If voltage is present, replace In/Out

motor.

“In-Out” switch failure

(on control panel).

Verify 24 vdc at pin 6 of P1 with “Out”

button pressed.

If voltage is not present at pin 6, re-

place “In-Out” switch (section F-1 of

chap 4).

Check for 24 vdc at pin 7 of P1. If voltage is not present, replace con-

troller.

Controller failure.

Check for 24 vdc at pin 6 of P2 with

“Deploy” button pressed.

If voltage is present, replace control-

ler.

Platform not fully

deployed.

Check for 24 vdc at pin 5 of P5. Press “Out” button on control panel.

Hydraulic quick-

disconnect hose fitting

to cylinder is not se-

cure.

Verify that quick-disconnect connector

is fully engaged.

If loose, remake connection.

Down valve failure

(part of hydraulic pump

assembly).

Check for 24 vdc at pin 4 of TS1. If voltage is present, replace down

valve (or entire hydraulic pump as-

sembly).

Platform

does not

lower.

Up-Down switch (on

control panel) failure.

Check for 24 vdc at pin 4 of P1. If voltage is not present, replace

switch (section F-1 of chap 4).

Loading...

Loading...