20160576

22

Installation

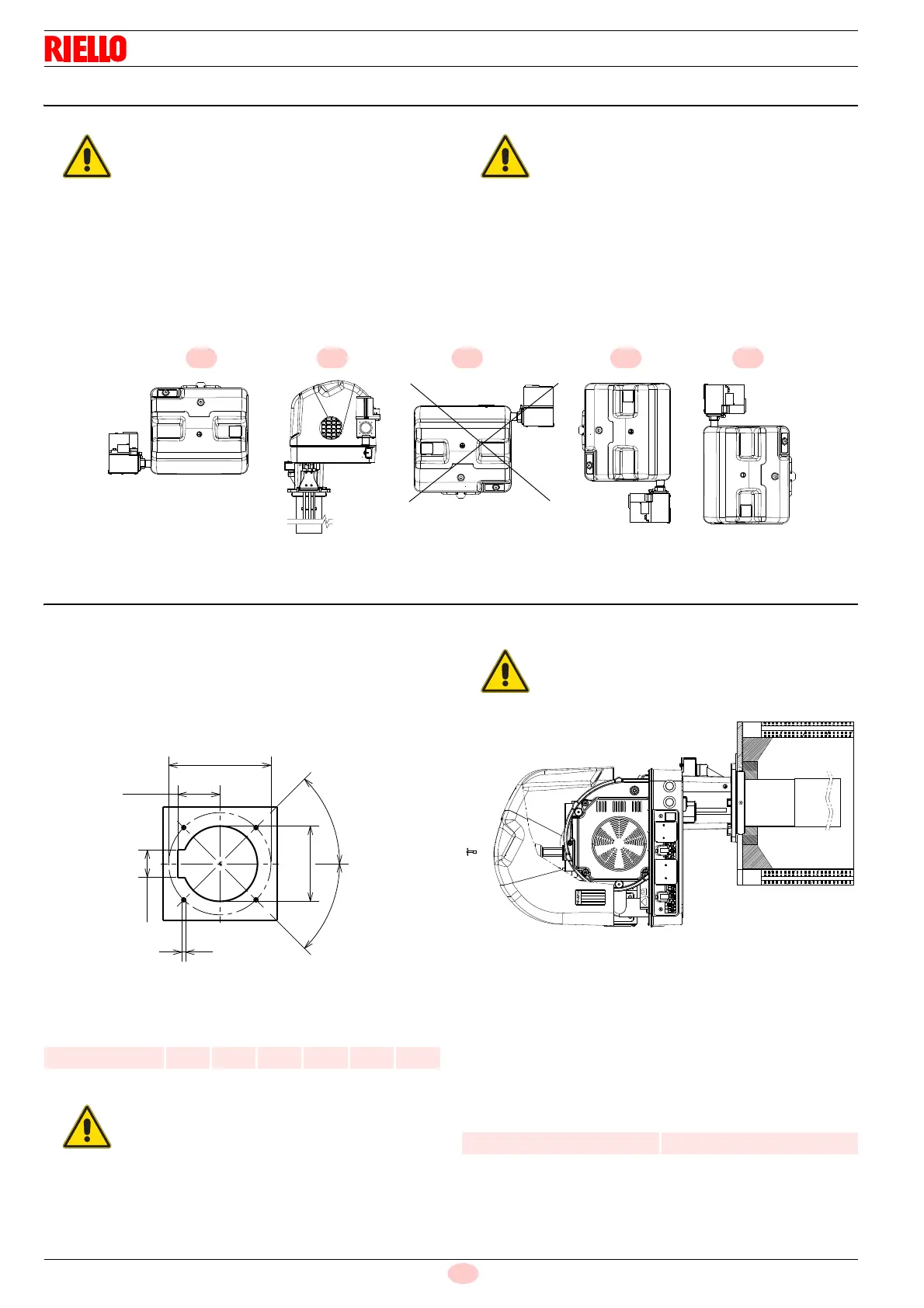

5.4 Operating position

5.5 Preparing the boiler

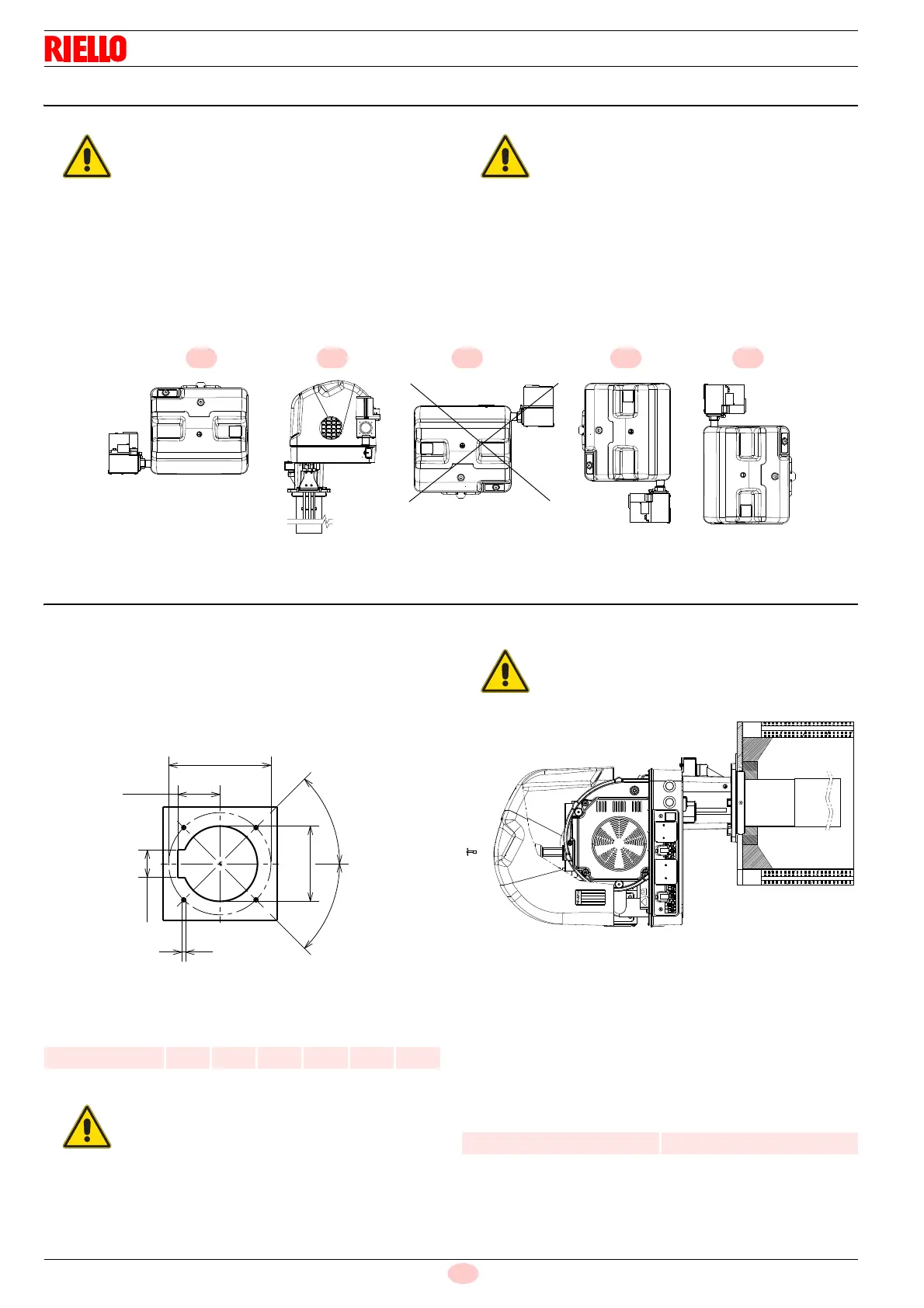

5.5.1 Boring the boiler plate

Pierce the closing plate of the combustion chamber, as in

(Fig. 15).

The position of the threaded holes can be marked using the ther-

mal insulation screen supplied with the burner.

Tab. L

It is possible to insert a protective device made of refractory

material between the combustion head and the boiler refractory.

This protective device must allow the blast tube to be taken out

(Fig. 16).

5.5.2 Head length

The length of the head must be selected according to the indica-

tions provided by the manufacturer of the boiler, and in any case

it must be greater than the thickness of the boiler door complete

with its fettling.

The range of lengths available, L (mm), is as follows:

Tab. M

The burner is designed to operate only in

positions 1, 2, 4 and 5 (Fig. 14).

Installation 1 is preferable, as it is the only

one that allows the maintenance operations

as described in this manual.

Installations 2, 4 and 5 allow operations to be

performed, but make maintenance and

inspection of the combustion head more diffi-

cult.

All the positions require the installation of the

gas valve with coils facing upwards or hori-

zontally (Fig. 14).

Any other position could compromise the cor-

rect operation of the appliance.

Installation 3 is prohibited for safety reasons.

Installation with the coils pointing downwards

is absolutely forbidden.

mm D1 W1 R DX2 DX1 W6

RX 180-250 S/PV 170 224 M 8 94 70 45°

The burners cannot be used on flame inversion

boilers.

Do not insert the protection in line with the elec-

trode unit, as this would compromise its good op-

eration.

mm Zona di non combustione

RX 180-250 S/PV 160

Loading...

Loading...