23

20140262

Installation

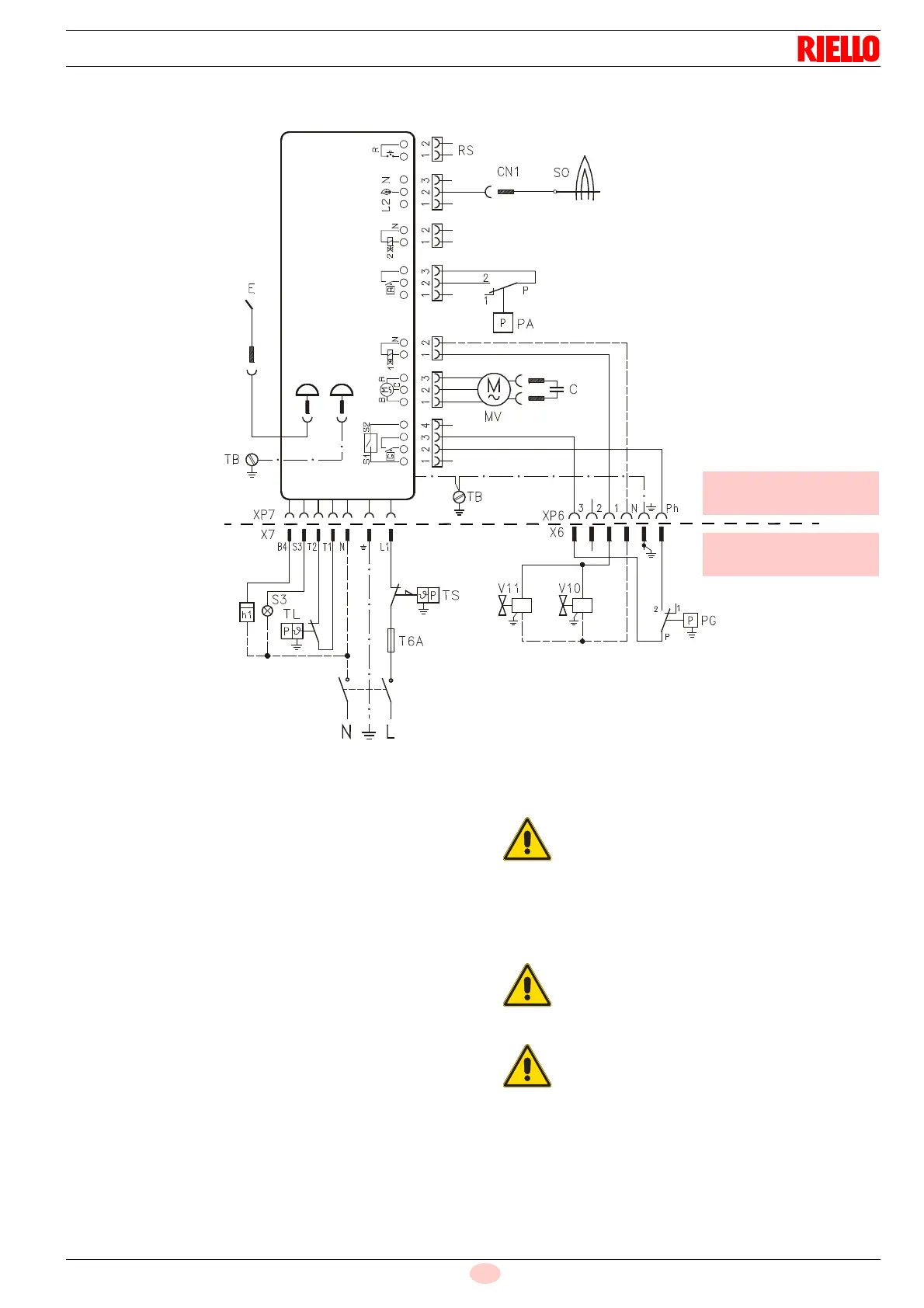

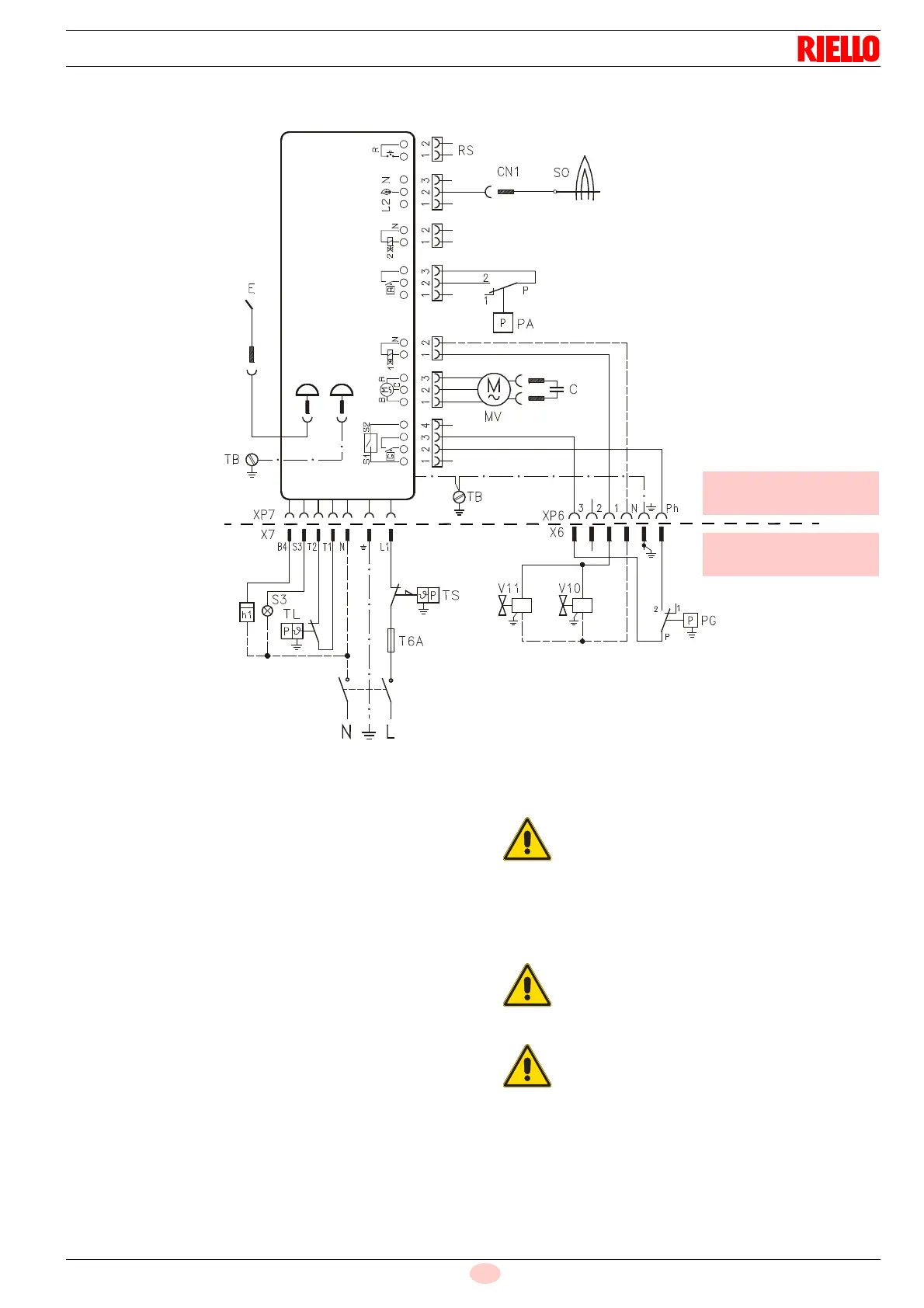

5.11.1 Electrical system carried out by the factory

Key

C Capacitor

CN1 Probe connector

EElectrode

h.. Hour counter

MV Motor

PA Minimum air pressure switch.

PG Minimum gas pressure switch

RS Remote reset

SO Ionisation probe

S3 Lockout signal (230V - 0.5A max.)

T6A Fuse

TB Burner earth

TL Limit thermostat

TS Safety thermostat

V10 Safety valve

V11 1st stage valve

X.. Plug

XP.. Socket

CARRIED OUT

AT THE FACTORY

Fig. 19

BY

THE INSTALLER

Main

230V ~ 50 Hz

D4626

CONTROL BOX

switch

Do not invert the neutral with the phase in the

electrical supply line.

Check that the electrical supply of the burner

corresponds to that shown on the identifica-

tion label and in this manual.

The section of the conductors must be at

least 1mm

2

. (Unless requested otherwise by

local standards and legislation).

Check the burner stops by opening the thermo-

stats and check it locks out by opening the con-

nector (CN1)(Fig. 19) inserted in the probe's red

wire, located on the outside of the control box.

If the cover is still on, remove it and proceed with

the electric wiring following the wiring diagrams.

Use flexible cables in compliance with EN 60 335-

1 standards.

Loading...

Loading...