19

20136874

Start-up, calibration and operation of the burner

6.1 Notes on safety for the first start-up

6.2 Combustion adjustment

In conformity with EN 267, the installation of the burner on the

boiler, the adjustment and testing must be carried out in compli-

ance with the instruction manual of the boiler, including control of

the CO and CO

2

concentration in the flue gases, their tempera-

ture and the average temperature of the water in the boiler.

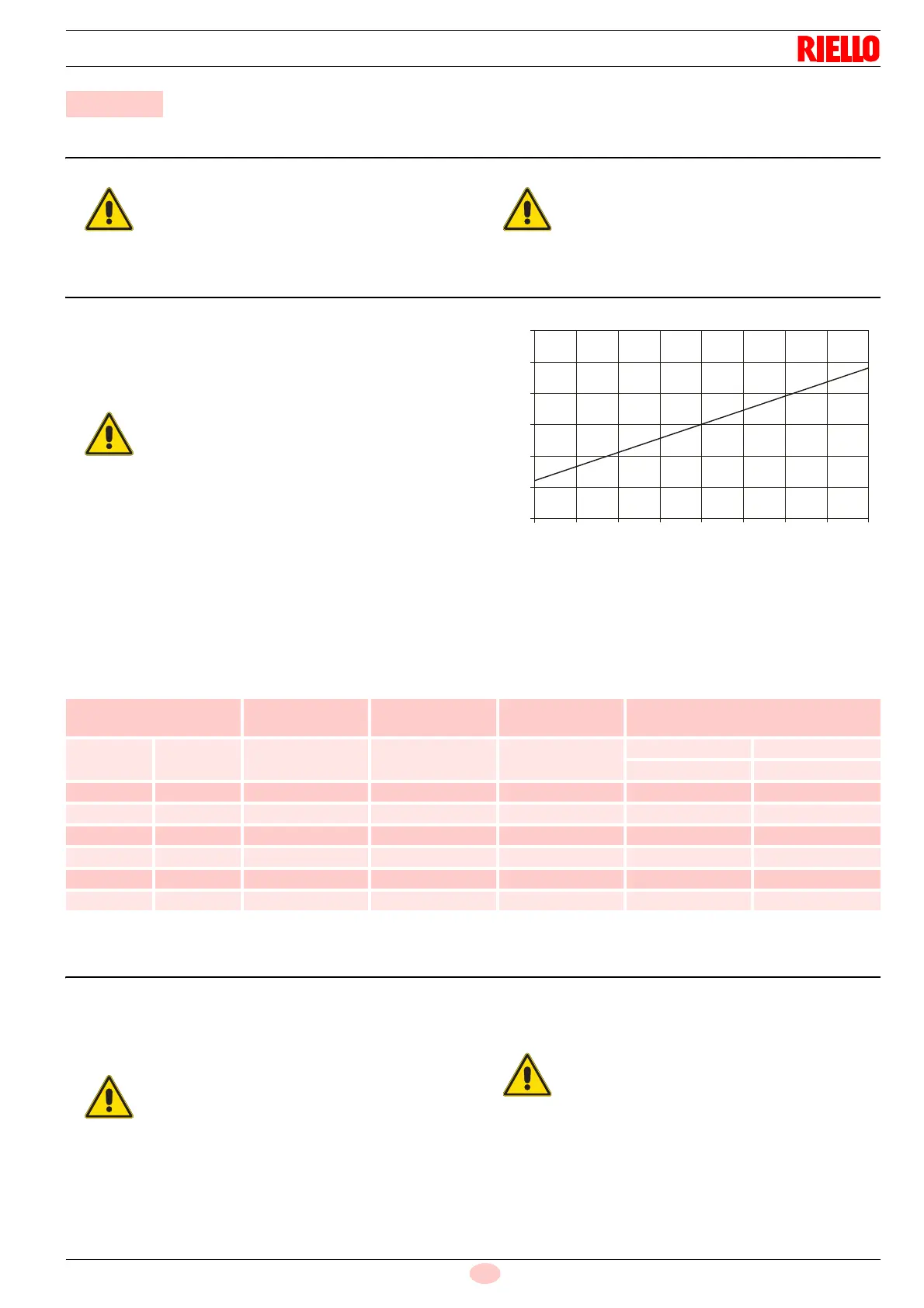

To suit the required boiler output, choose the nozzle, the pump

pressure and the adjustment of the air damper according to the

following table.

The values in Tab. G refer to 12.5% of CO

2

at sea level, and

with a light oil and ambient temperature of 20°C.

Tab. G

6.3 Recommended nozzles

The burner complies with the emission requirements of the EN

267 standard. In order to guarantee that emissions do not vary,

recommended and/or alternative nozzles specified by manufac-

turer in the Instruction and warning booklet should be used.

Steinen type S - SS

Danfoss type S - B

Delavan type B - W

Monarch type R

6 Start-up, calibration and operation of the burner

The first start-up of the burner must be carried out

by qualified personnel, as indicated in this manual

and in compliance with the standards and regula-

tions of the laws in force.

Check the correct working of the adjustment, com-

mand and safety devices.

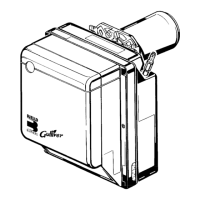

The temperature of the combustion air (relative to

the place where the burner is installed) may vary

during the season, it influences the CO

2

of the

burner.

We recommend adjusting the CO

2

based

upon the temperature of the combustion air at the

time when the burner calibration is carried out in

accordance with what is shown in the following di-

agram.

E.g. with combustion air temperature of 10°C, ad-

just the CO

2

to 12.5%.

% CO

2

External air temperature (°C)

14.5

14.0

13.5

13.0

12.5

12.0

11.5

0 5 10 15 20 25 30 35 40

D4604

Fig. 18

Nozzle

Pump

Pressure

Burner

output

Combustion head

adjustment

Air damper

adjustment

GPH Angle bar kg/h ± 4% Set-point

Low flame High flame

Set-point Set-point

2.50 60° 12 10.0 0 0.2 1.4

3.00 60° 12 12.0 1 0.4 2.1

3.50 60° 12 14.0 2.5 0.7 3.0

4.00 60° 12 16.1 4 0.9 3.5

4.50 60° 12 18.1 6 1.4 4.5

4.50 60° 14 19.5 6 1.4 6.0

It is advisable to replace nozzles every year dur-

ing regular maintenance operations.

The use of nozzles other than those specified by

manufacturer and inadequate regular mainte-

nance may result into emission limits non-con-

forming to the values set forth by the regulations

in force, and in extremely serious cases, into po-

tential hazards to people and objects.

The manufacturing company shall not be liable for

any such damage arising from non-observance of

the requirements contained in this manual.

Loading...

Loading...