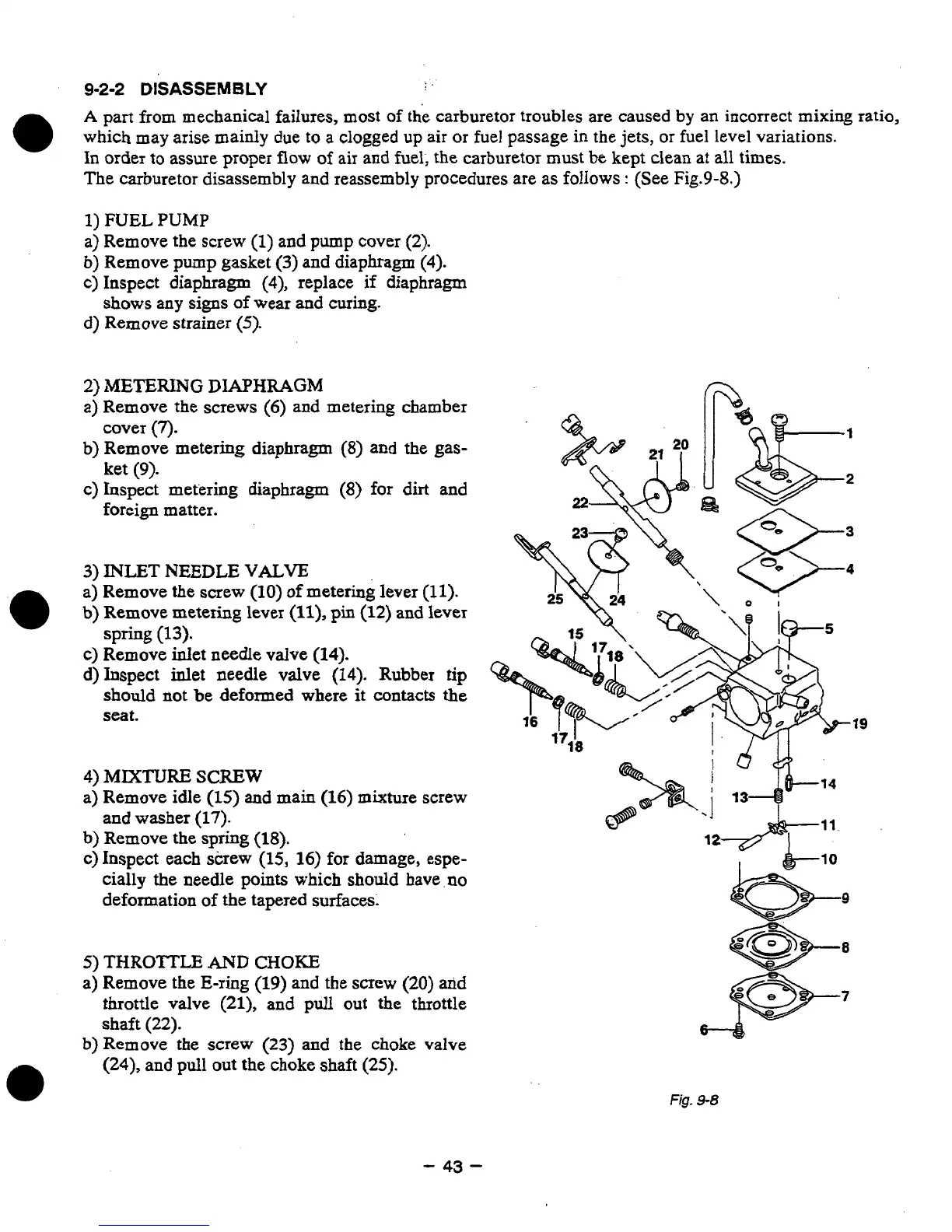

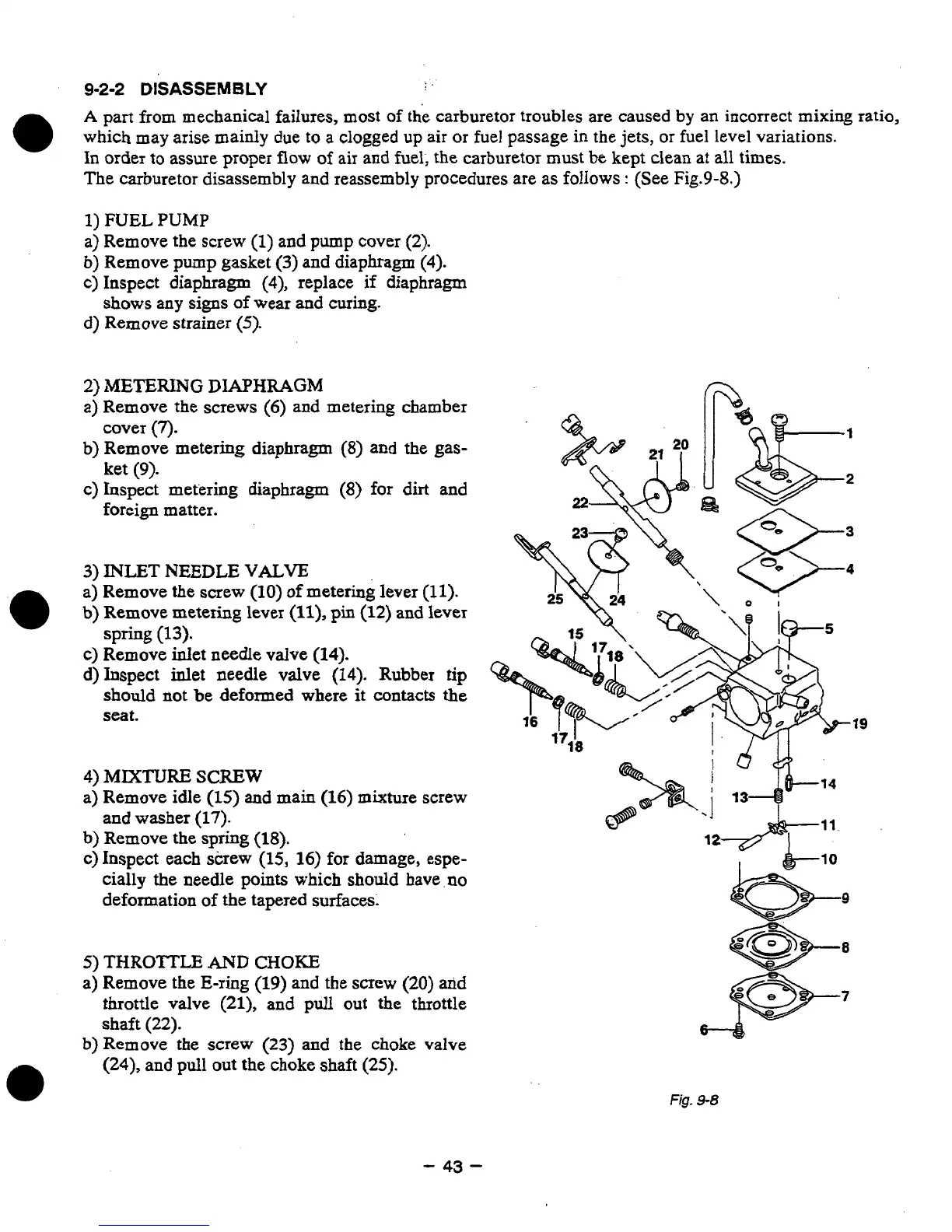

9-2-2

DISASSEMBLY

I.

A

part from mechanical failures, most of the carburetor troubles are caused

by

an incorrect mixing ratio,

In order

to

assure proper

flow

of air and fuel; the carburetor must

be

kept clean at all times.

The carburetor disassembly

and

reassembly procedures are

as

follows

:

(See

Fig.9-8.)

which may arise mainly

due

to

a

clogged

up

air or fuel passage in the jets,

or

fuel level variations.

1)

FUEL

PUMP

a)

Remove the screw

(1)

and

pump

cover

(2).

b)

Remove pump gasket

(3)

and diaphragm

(4).

c)

Inspect diaphragm

(4),

replace

if

diaphragm

d)

Remove strainer

(5).

shows

any

signs

of

wear

and

curing.

2)

METERING

DIAPHRAGM

a) Remove the screws

(6)

and metering chamber

b) Remove metering diaphragm

(8)

and the

gas-

c)

Inspect metering diaphragm

(8)

for

dirt

and

cover

(7).

ket

(9).

foreign matter.

3)

INLET

NEEDLE

VALVE

a) Remove the

screw

(10)

of

metering lever

(11).

b)

Remove metering lever

(ll),

pin

(12)

and lever

spring

(13).

c)

Remove inlet needle valve

(14).

d) Inspect inlet needle valve

(14).

Rubber tip

should

not

be deformed where

it

contacts

the

seat.

4)

MIXTURE

SCREW

a) Remove idle

(15)

and main

(16)

mixture screw

and

washer

(17).

b)

Remove the spring

(18).

c)

Inspect each screw

(15,

16)

for damage, espe-

cially the needle

points

which should have.

no

deformation of the tapered surfaces.

5)

THROTT'LE

AND

CHOKE

a)

Remove the E-ring

(19)

and

the screw

(20)

and

throttle valve

(21),

and pull

out

the throttle

shaft

(22).

b)

Remove

the

screw

(23)

and

the choke valve

8

7

a

(24),

and pull

out

the choke shaft

(25).

-

43

-

Fig.

9-8

Loading...

Loading...