Rockwell Automation Publication 2080-UM002N-EN-E - November 2022 313

Appendix D Troubleshooting

Corrective Action for Recoverable and Non-recoverable Faults

Corrective Actions for Recoverable Faults

Perform the following:

1. Optionally save the fault log from Connected Components Workbench software.

2. Clear the recoverable fault using Connected Components Workbench software.

3. If problem persists, contact technical support with the fault log.

Corrective Actions for Non-recoverable Faults

Perform the following:

1. Power cycle your Micro800 controller.

2. Controller will go to recoverable fault. Optionally save the fault log from Connected

Components Workbench software.

3. Clear the recoverable fault using Connected Components Workbench software.

4. If program is lost, build and download your program using Connected Components

Workbench software.

5. If problem persists, contact technical support with the fault log.

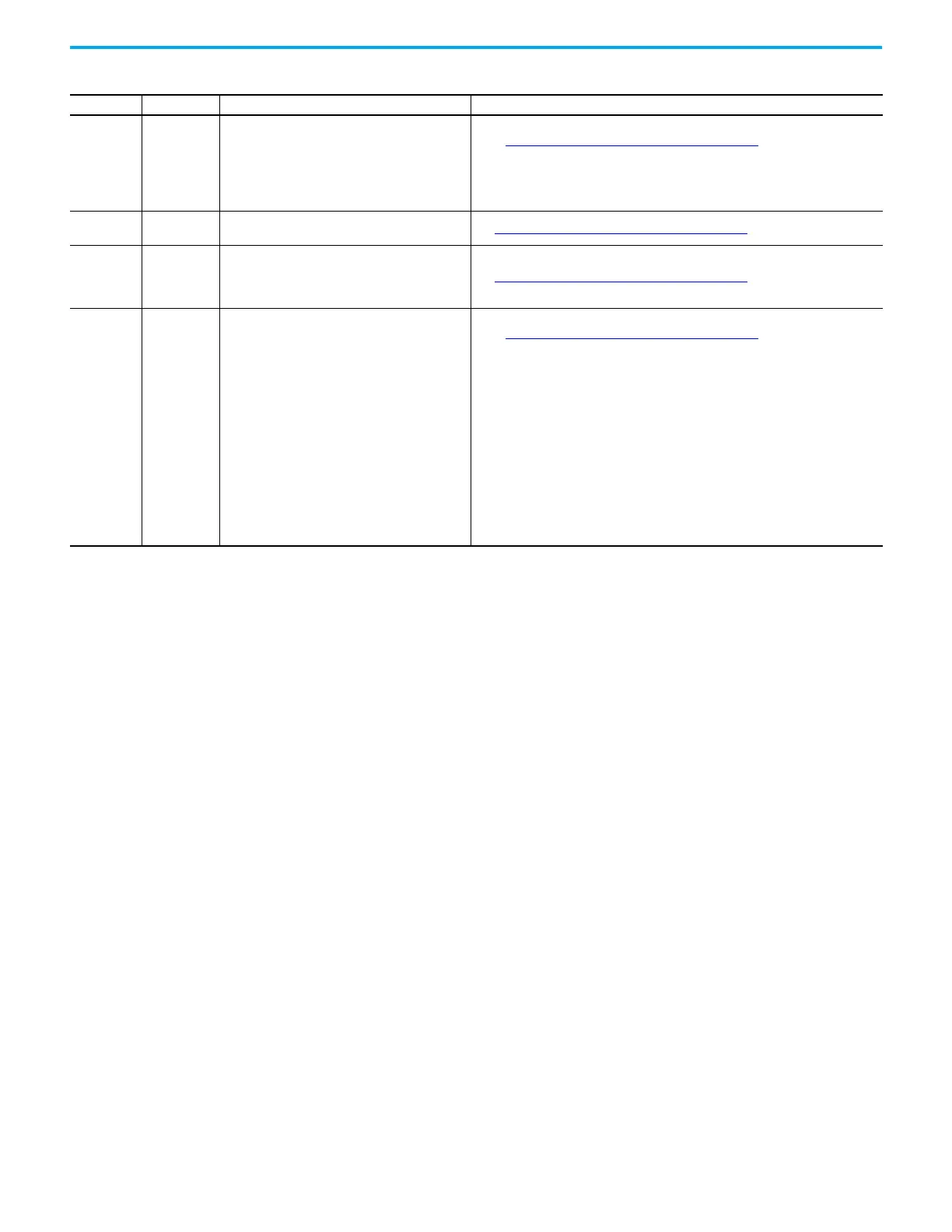

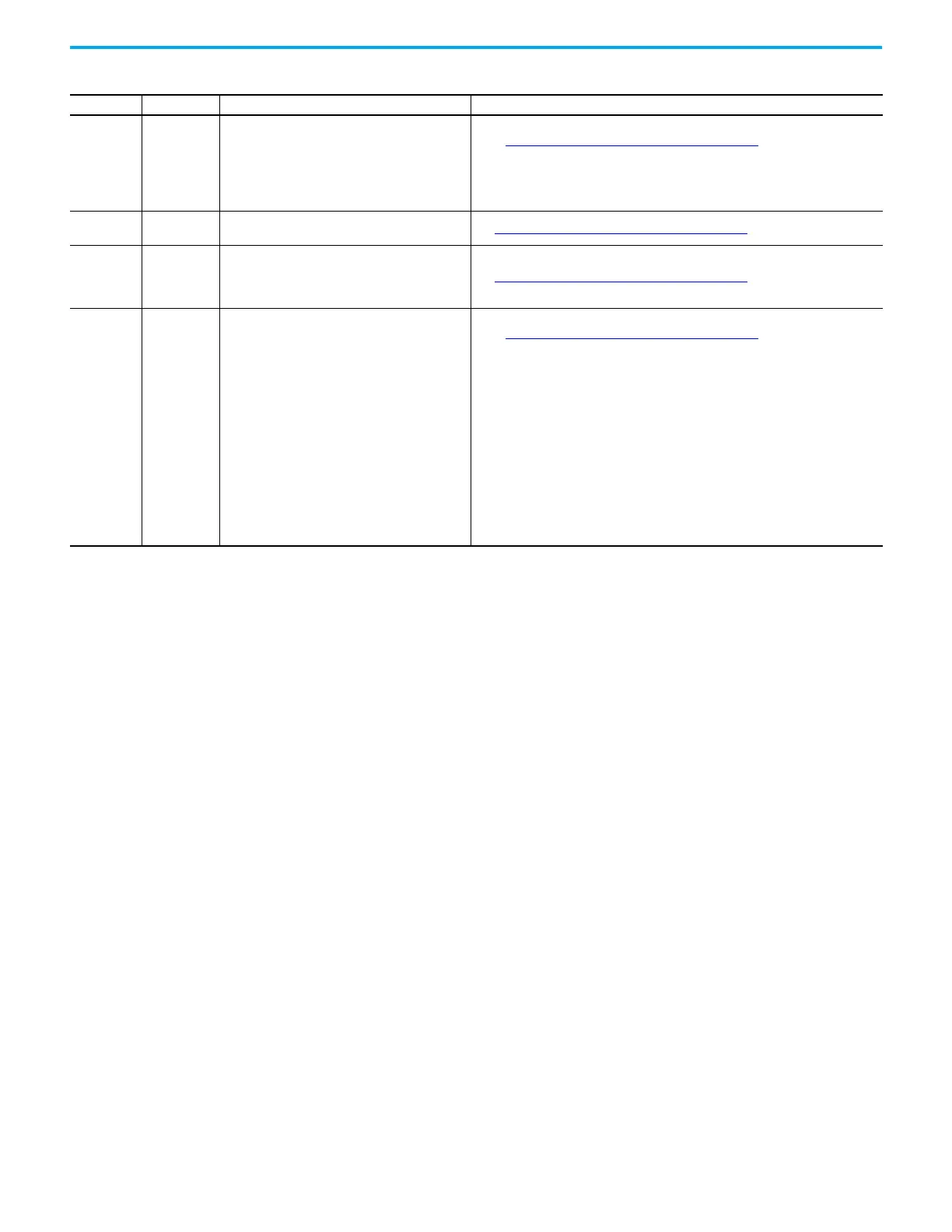

0xF8A1 Recoverable The DOY parameters are invalid.

Perform the following:

1. See Corrective Actions for Recoverable Faults

on page 313.

2. Correct the program to ensure that there are no invalid parameters.

3. Build and download the program using Connected Components Workbench

software.

4. Put the Micro800 controller into Run mode.

0xFFzz

(4)

Recoverable

A user-created fault from the Connected

Components Workbench software has occurred.

See Corrective Actions for Recoverable Faults on page 313.

0xD00F Recoverable

A particular hardware type (for example, embedded

I/O) was selected in the user program

configuration, but did not match the actual

hardware base.

See Corrective Actions for Recoverable Faults

on page 313.

0xD011 Recoverable

The program scan time exceeded the watchdog

timeout value.

Perform the following:

• See Corrective Actions for Recoverable Faults on page 313.

• Determine if the program is caught in a loop and correct the problem.

Fault may occur if your Structured Text program contains a For loop with the upper

limit set to the maximum value of the variable. For example, the variable is a USINT

and the limit is set to 255, or the variable is a UINT and the limit is set to 65535.

To correct the fault, perform the following:

1. Correct the program to ensure that the upper limit is not reached. One method is to

use a data type with a larger maximum value.

2. Build and download the program using Connected Components Workbench

software.

3. Put the Micro800 controller into Run mode.

If your program is designed to have a scan time of longer than 3 seconds, in the user

program, increase the watchdog timeout value that is set in the system variable

_SYSVA_TCYWDG and then build and download the program using Connected

Components Workbench software.

(1) z indicates the logic axis ID. (0...3)

(2) z indicates the slot number of the expansion I/O. If z=0, then the slot number cannot be identified.

(3) z is the slot number of the plug-in module. If z = 0, then the slot number cannot be identified.

(4) zz indicates the last byte of the program number. Only program numbers up to 0xFF can be displayed. For program numbers 01x00 to 0xFFFF, only the last byte is displayed.)

Table 77 - List of Error Codes for Micro800 controllers (Continued)

Error Code Fault Type Description Recommended Action

Loading...

Loading...