Rockwell Automation Publication 2198-UM005C-EN-P - February 2022 161

Chapter 9 Kinetix 5300 Safe Torque Off Function

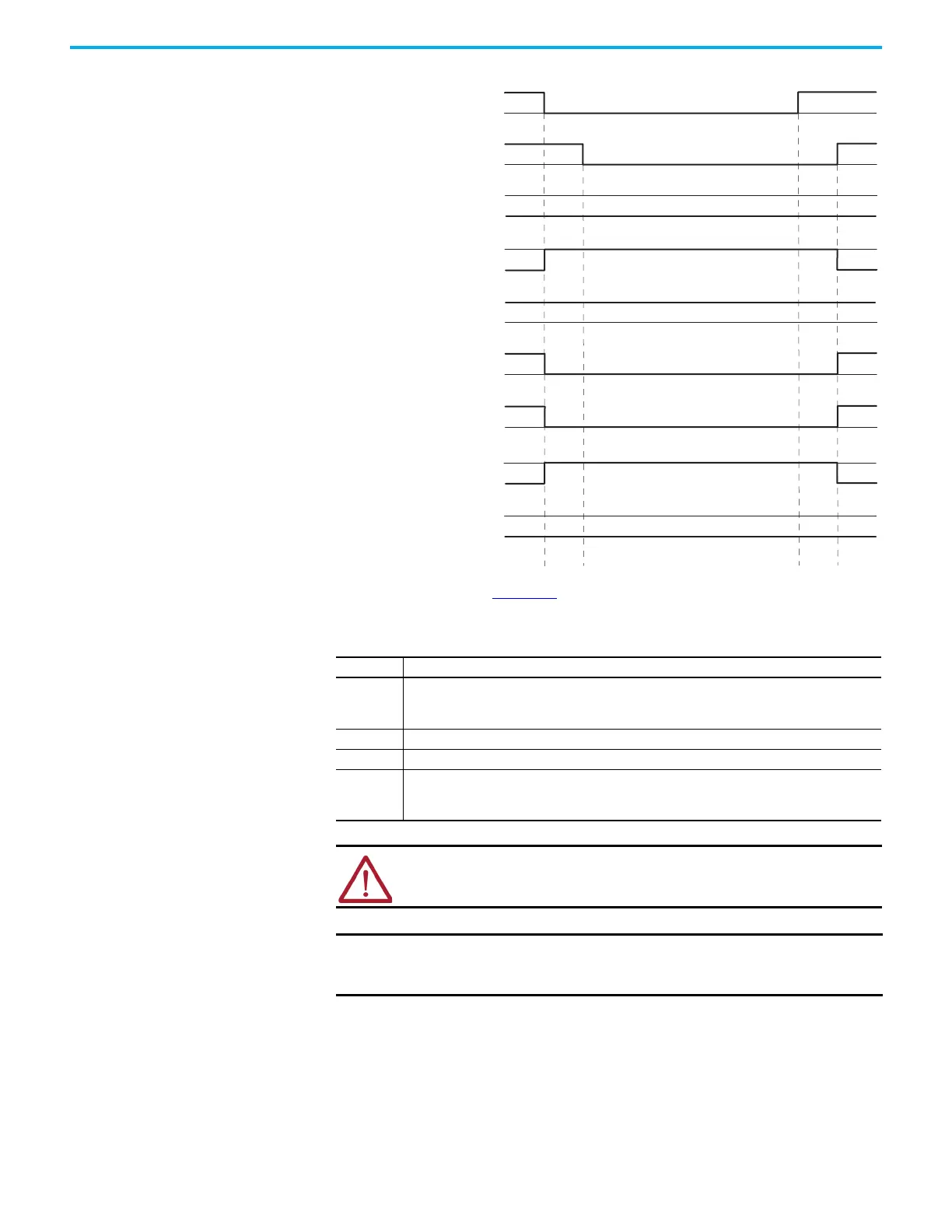

Figure 69 - Normal System Operation

All status attributes in Figure 69 are for status purposes only and should not be

used as a condition for motion.

1 2 3 4

24V DC

24V DC

0V DC

0V DC

1

1

0

0

0

1

1

0

1

0

0

1

1

0

GuardStopRequestStatus

GuardStopInputFault

SS_IN_CH0

SS_IN_CH1

GuardStopInputStatus

GuardGateDriveOutputStatus

GuardOkStatus

GuardFault

SafeTorqueOffInhibit

Event

Table 81 - Normal System Operation Legend

Event Description

1

SS_IN_CH0 is removed.

• GuardGateDriveOutputStatus, GuardOkStatus, and GuardStopInputStatus = 1

• SafeTorqueOffInhibit, GuardFault, GuardStopRequestStatus and GuardStopInputFault = 0

2 SS_IN_CH1 is removed < 1 second

3 SS_IN_CH0 is re-applied

4

SS_IN_CH1 is re-applied < 1 second of S1 or Event 3

• SafeTorqueOffInhibit, GuardOkStatus, and GuardStopRequestStatus = 1

• GuardFault, GuardGateDriveOutputStatus, GuardStopInputStatus and GuardStopInputFault = 0

ATTENTION: Permanent magnet motors can, in the event of two simultaneous

faults in the IGBT circuit, result in a rotation of up to 180 electrical degrees.

IMPORTANT If any of the STO inputs are de-energized, the Start Inhibit field indicates

SafeTorqueOffInhibit and GuardStopRequestStatus bit of AxisGuardStatus

tag set to 1.

Loading...

Loading...