14 Rockwell Automation Publication 2198-IN001D-EN-P - February 2016

Kinetix 5500 Servo Drives

Shared AC/DC and Hybrid Systems

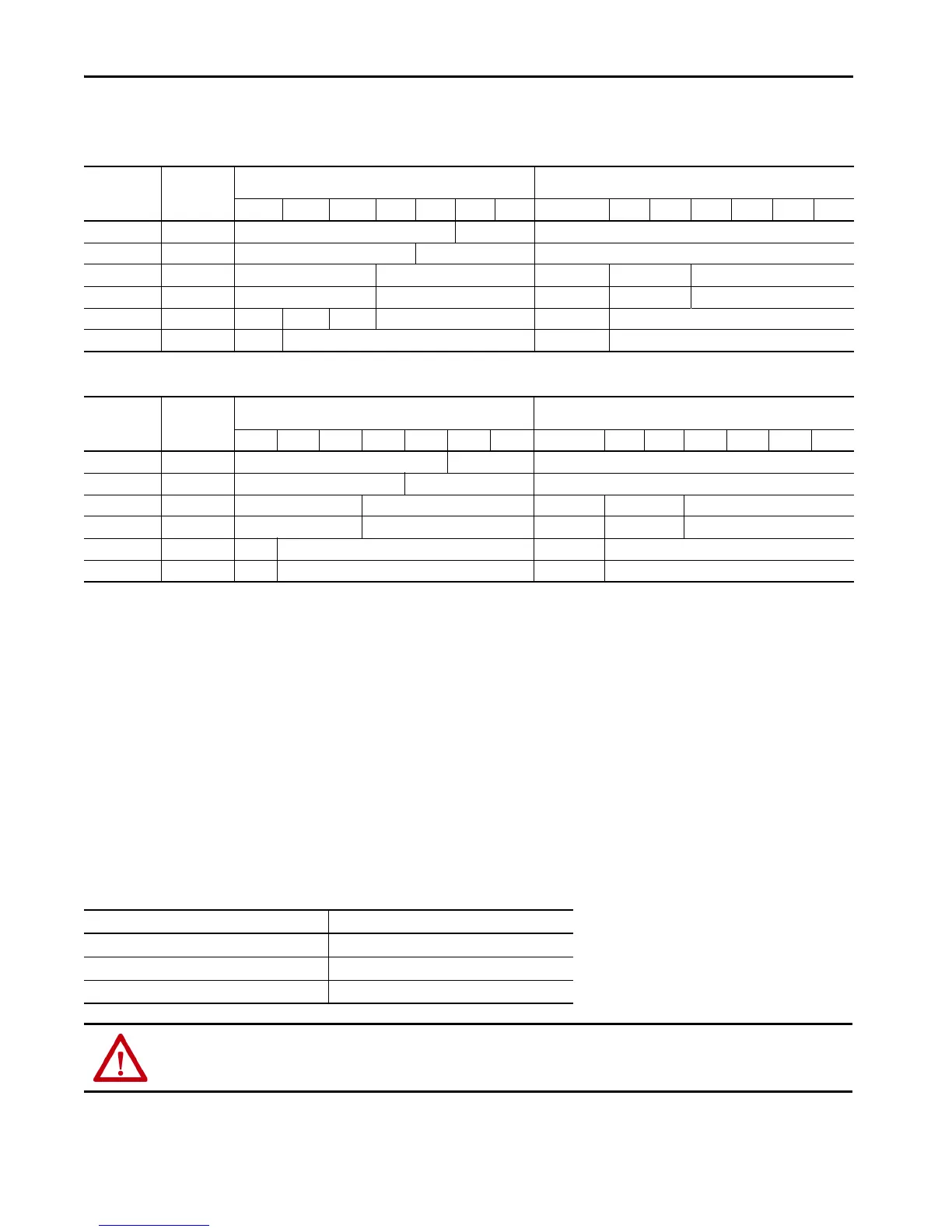

Input Power UL Circuit-protection Specifications

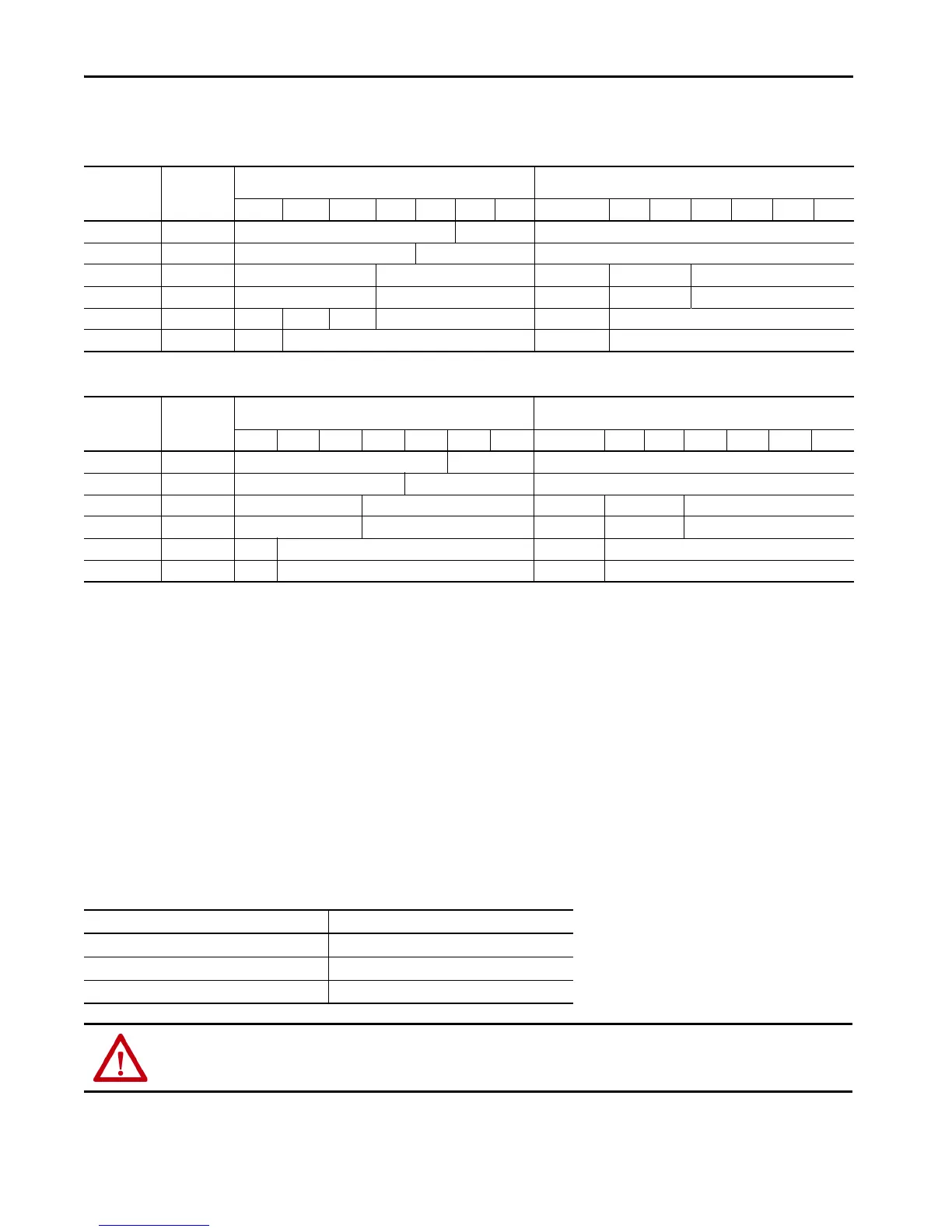

Input Power IEC (non-UL) Circuit-protection Specifications

Motor Overload Protection

This servo drive uses solid-state motor overload protection that operates in accordance with UL requirements. Motor overload protection is

provided by algorithms (thermal memory) that predict actual motor temperature that is based on operating conditions.

In addition to thermal memory protection, this drive provides an input for an external temperature sensor/thermistor device, embedded in the

motor, to support the UL requirement for motor overload protection.

Servo drives using DSL (digital servo link) encoder technology require the encoder to perform motor temperature monitoring and transmit the

data over the single motor cable. Kinetix VP motors use DSL technology that performs this function. No additional wiring is required.

Some motors supported by this drive (firmware revision 3.001 or earlier) do not contain temperature sensors/thermistors; therefore, motor

overload protection against excessive consecutive motor overloads with power cycling is not supported. Beginning with firmware revision 4.001

(and later) thermal retention is supported regardless of the motor or encoder type in use.

This servo drive meets the following UL requirements for solid-state overload protection.

Refer to your servo drive user manual for the interconnect diagram that illustrates the wiring between your motor and drive.

Kinetix 5500

Drive Cat. No.

Drive Voltage,

(three-phase)

nom

Bussmann Fuse

Cat. No.

Molded Case CB

Cat. No.

2 Axes 3 Axes 4 Axes 5 Axes 6 Axes 7 Axes 8 Axes 2 Axes 3 Axes 4 Axes 5 Axes 6 Axes 7 Axes 8 Axes

2198-H003-ERSx 240/480V KTK-R-10 KTK-R-15 N/A

2198-H008-ERSx 240/480V KTK-R-15 KTK-R-20 N/A

2198-H015-ERSx 240/480V KTK-R-20 N/A 140U-D6D3-C15 140U-D6D3-C20 N/A

2198-H025-ERSx 240/480V KTK-R-30 N/A 140U-D6D3-C20 140U-D6D3-C30 N/A

2198-H040-ERSx 240/480V KTK-R-30 LPJ-45SP LPJ-50SP N/A 140U-D6D3-C30 N/A

2198-H070-ERSx 240/480V LPJ-50SP N/A 140G-G6C3-C50 N/A

Kinetix 5500

Drives Cat. No.

Drive Voltage,

(three-phase)

nom

DIN gG Fuses

Amps (max)

Molded Case CB

Cat. No.

2 Axes 3 Axes 4 Axes 5 Axes 6 Axes 7 Axes 8 Axes 2 Axes 3 Axes 4 Axes 5 Axes 6 Axes 7 Axes 8 Axes

2198-H003-ERSx 240/480V 10 16 N/A

2198-H008-ERSx 240/480V 16 N/A N/A

2198-H015-ERSx 240/480V 20 N/A 140U-D6D3-C15 140U-D6D3-C20 N/A

2198-H025-ERSx 240/480V 32 N/A 140U-D6D3-C20 140U-D6D3-C30 N/A

2198-H040-ERSx 240/480V 32 N/A 140U-D6D3-C30 N/A

2198-H070-ERSx 240/480V 50 N/A 140G-G6C3-C50 N/A

Motor Overload Protection Trip Point Value

Ultimately 100% overload

Within 8 minutes 200% overload

Within 20 seconds 600% overload

ATTENTION: To avoid damage to your motor due to overheating caused by excessive, successive motor overload trips, follow the wiring diagram provided in

the user manual for your motor and drive combination.

Loading...

Loading...