140 Rockwell Automation Publication 2080-UM002N-EN-E - November 2022

Chapter 8 EtherNet/IP Network

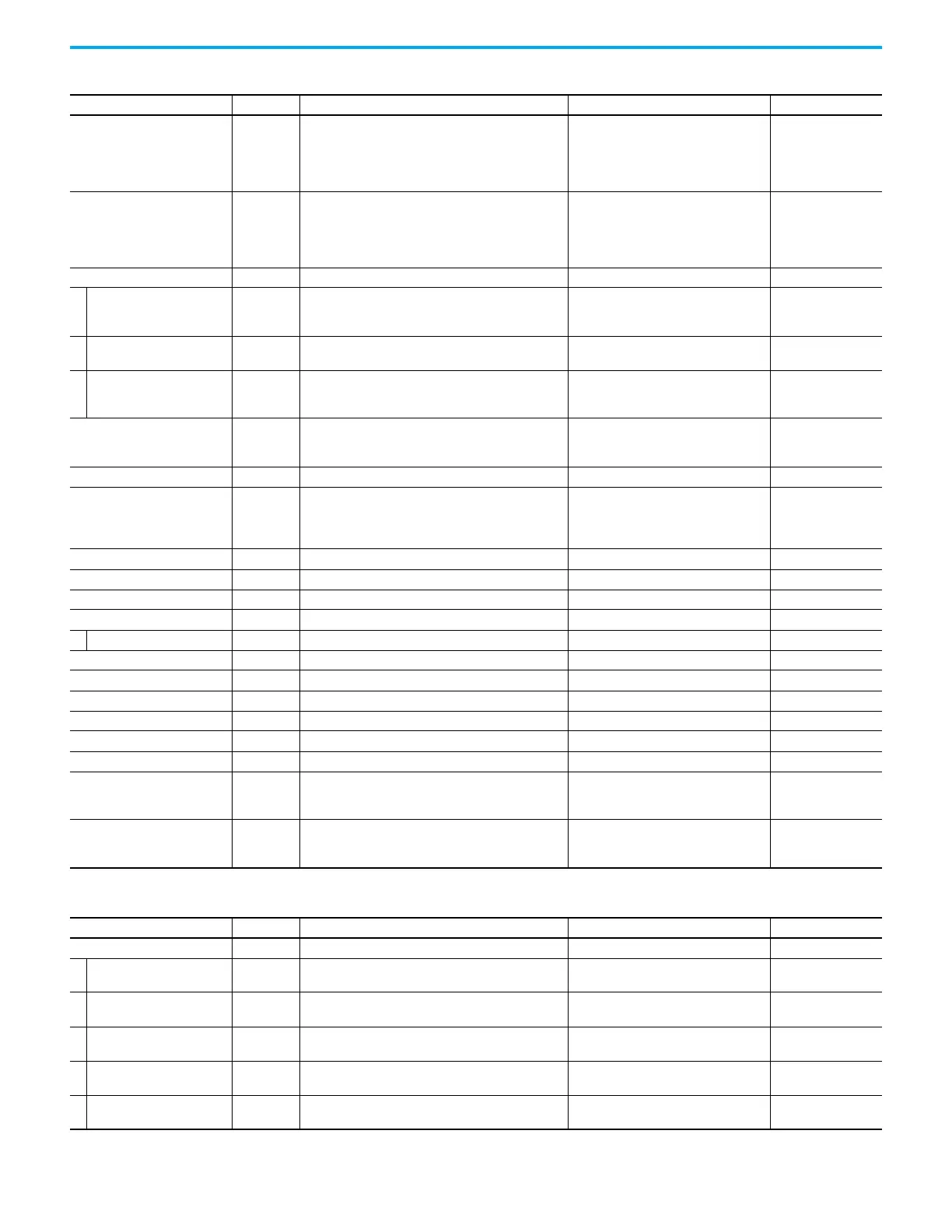

CylicMoveType SINT

Enumerated value used to determine the cyclic move

type.

-128…-1 = Reserved

0 = Rotary positive

1 = Rotary negative

2 = Rotary shortest path

3…127 = Reserved

TravelMode DINT

Enumerated value used to determine the travel

constraints of the axis.

-128…+1 = Reserved

2 = Non-cyclic move

3…9 = Reserved

10 = Cyclic move

11…127 = Reserved

PositionControl SINT

PositionControl.0 BIT

When executing a motion command, the next

movement can override the previous movement.

0 = Does not override the previous

movement

1 = Can override the previous movement

PositionCommandOve

rride

PositionControl.1 BIT

The next movement can overlap the end of the current

movement.

0 = Does not overlap the next movement

1 = Overlaps the next movement

PositionCommandOve

rlap

PositionControl.2 BIT

Selects between the high-speed digital inputs that are

used to capture position feedback.

Vendor specific

0 = DI9 is selected

1 = DI10 is selected

CapturedPositionSele

ct

TorqueReference DINT

Represents the output torque level when the operation

mode is Torque Mode (3). This value is in percent of

motor rated torque.

-4000…+4000 (enumeration is 0.1x)

TorqueRampTime DINT Represents the time to reach the torque reference. 1…65500 ms

StartingIndex SINT

The first index (position register) that the drive should

execute.

-128…-1 = Reserved

0 = PR 0: Homing

1…99 = PR 1…PR 99

100…127 = Reserved

CamMasterReference SINT

CamExecutionSchedule SINT Future

CamExecutionMode SINT Future

CamSetting SINT Future

CamSetting3 BIT Future CamStopMode

CamSlaveScaling DINT Future

CamLockPosition DINT Future

CamMasterLockPosition DINT Future

CamMasterLeadingCounts DINT Future

CamMasterUnlockCounts DINT Future

CamMasterCyclicLeadingCounts DINT Future

GearRatioSlaveCounts DINT

Integer value that represents slave counts. This value is

P1.044 Gear Ratio Follower Counts from the E-gear ratio

in Kinetix 5100 software.

GearRatioMasterCounts DINT

Integer value that represents master counts. This value

is P1.045 Gear Ratio Master Counts from the E-gear

ratio in Kinetix 5100 software.

Table 18 - Kinetix 5100 Motion Drive Output Assembly Data (Continued)

Name Data Type Description Value Comment

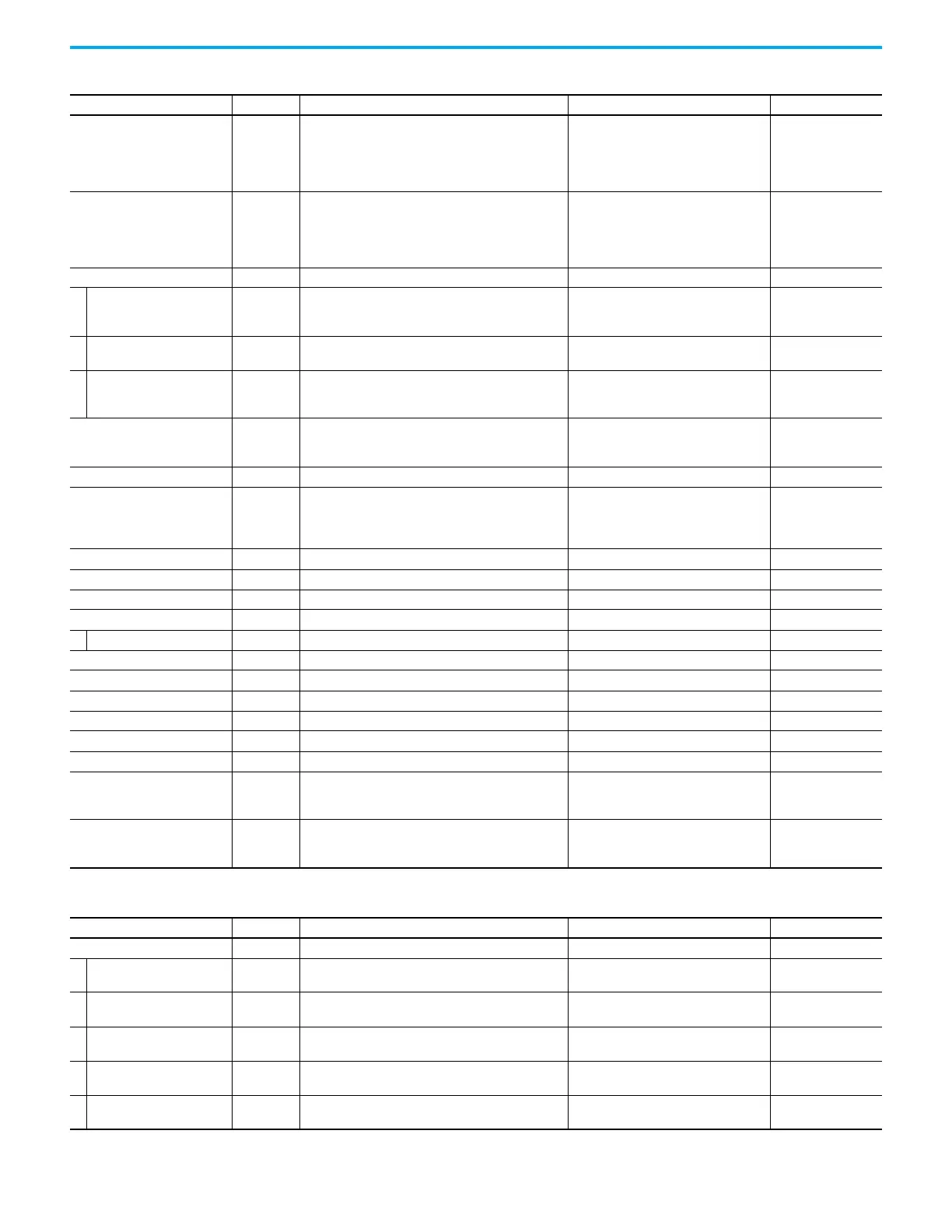

Table 19 - PowerFlex 520-series Drive Input Assembly Data (Position Mode)

Name Data Type Description Value Comment

DriveStatus INT

DriveStatus.0 BIT Indicates whether the drive is ready for operation.

0 = Not ready

1 = Ready

Ready

DriveStatus.1 BIT Indicates whether the drive is operating.

0 = Not active

1 = Active (Running)

Active

DriveStatus.2 BIT Indicates the command direction.

0 = Cmd reverse

1 = Cmd forward

CommandDir

DriveStatus.3 BIT Indicates the rotating direction.

0 = Rotating reverse

1 = Rotating forward

ActualDir

DriveStatus.4 BIT Indicates the acceleration state.

0 = Not accelerating

1 = Accelerating

Accelerating

Loading...

Loading...