Publication 2098-IN005C-EN-P — March 2008

132 Interconnect Diagrams

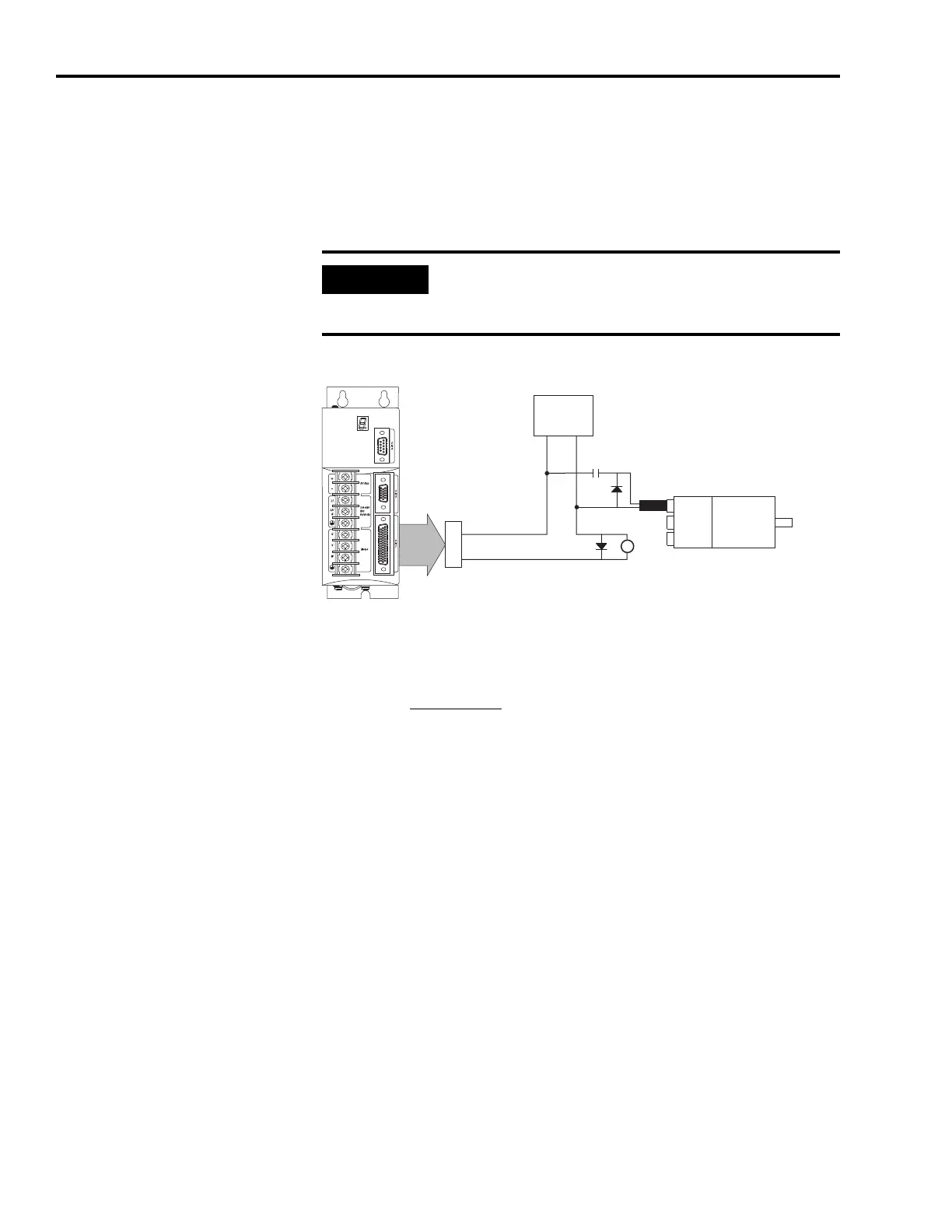

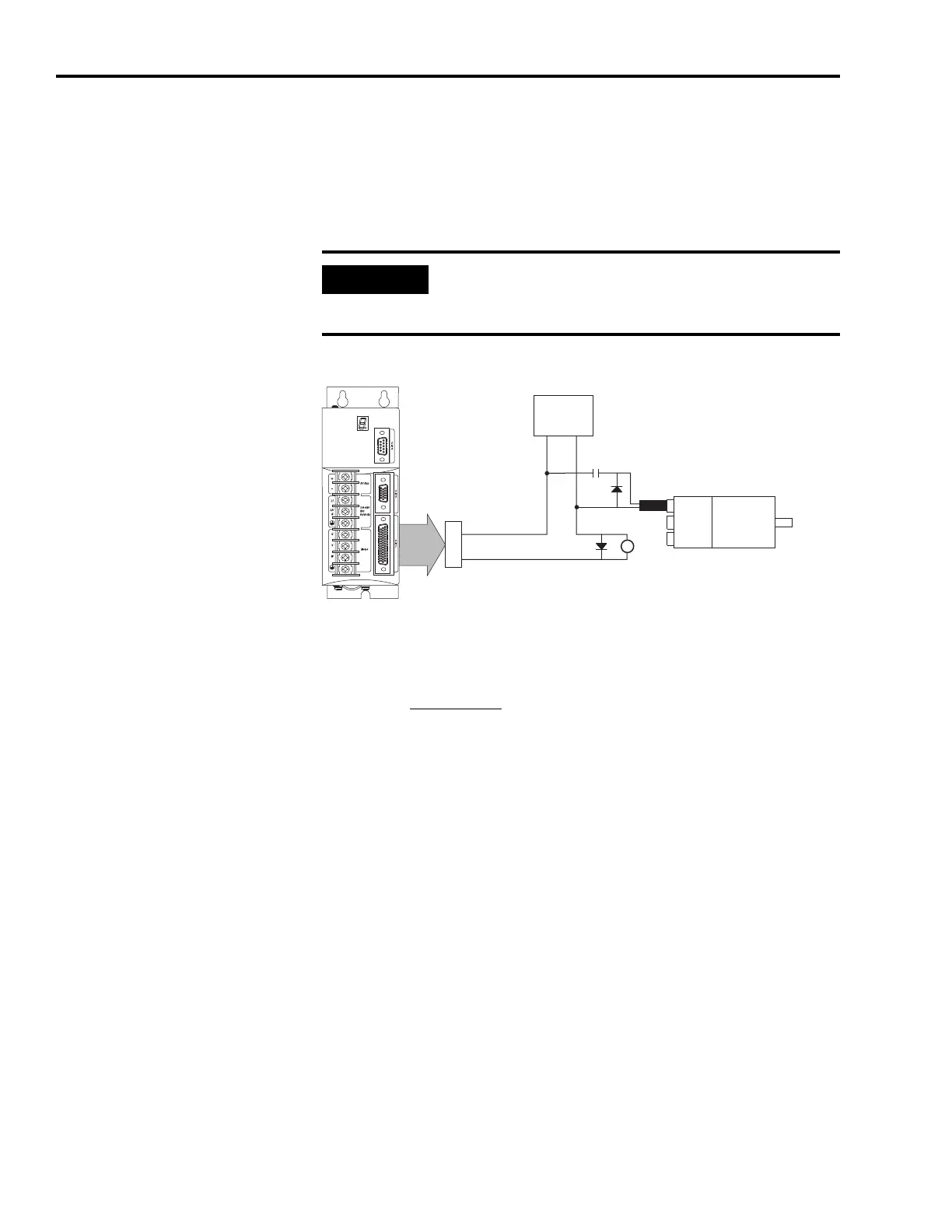

A separate power source is required to disengage the brake.

Removing power causes the brake to engage, but may also cause

electrical arcing to occur at the relay contacts until the brake power

dissipates. A customer-supplied diode or metal oxide varistor (MOV)

is recommended to prevent arcing. Use of an MOV can also reduce

the time to mechanically engage the brake.

Example Configuration Controlling a Motor Brake

(1)

Flyback diode (1N4004 rated 1.0 A @ 400V dc) suppresses collapsing field of brake coil.

(2)

For non-SERCOS drive, the relay output (CN1-43 and CN1-44) must be configured as a brake.

For more information on minimizing electrical noise, refer to the

System Design for Control of Electrical Noise Reference Manual,

publication GMC-RM001

.

Electrical arcing may occur at the relay contacts until the brake

power dissipates. A customer-supplied diode or metal oxide

varistor (MOV) is recommended to prevent arcing.

CN1

43

44

N.O. Relay Output +

N.O. Relay Output -

CR1

Brake

Feedback

Power

Power Supply

3 A @ 24V dc

+

_

CR1

(1)

(2)

(1)

Loading...

Loading...