Rockwell Automation Publication DRIVES-AT005D-EN-P - May 2022 33

Chapter 3 Shared DC Bus Configuration (Piggyback)

PowerFlex TL/TR Drives, Frame 8

Consult technical support when trying to configure piggyback configurations with a PowerFlex 755TL/TR frame 8 drive.

PowerFlex TL/TR Drives, Frame 9…15

PowerFlex 755TL/TR frames 9…15 require extension of the DC bus bar to connect additional inverters in a piggyback configuration. Additional

cabinet space with the necessary DC bus bar and DC bus bar splices must be specified. For more information on the DC Bus Bar and DC Bus Bar

splice kits available, see the PowerFlex 755TM IP00 Open Type Kits Technical Data, publication 750-TD101.

Sizing Shared Bus Supply AC Drive

Use the following methods to size the PowerFlex 755TL/TR AC drive. The highest power AC motor should be connected to the PowerFlex 755TL/TR

AC drive.

Basic Sizing of the PowerFlex 755TL/TR AC Drive

To perform the basic sizing calculations, you need the following information:

• Motor nameplate power rating

• Motor nameplate efficiency

• Product family and catalog numbers for each inverter/drive connected on the common DC bus

• Application overload duty normal duty (ND) or heavy duty (HD)

1. Convert all motor powers to kW (kW = HP x 0.746).

2. Calculate the required drive AC output power by dividing each motor nameplate power by the motor efficiency. Assume that the motors are

motoring at 100% of rating.

3. Sum the calculated AC output power of all the inverters/drives. Choose the application overload duty rating. All motors must be the same

overload duty rating, either normal duty (ND) or heavy duty (HD).

4. Select PowerFlex 755TL/TR AC drive that meets or exceeds the calculated AC output power value and overload duty rating from Step 3. See

the PowerFlex 755TL/TR AC drive fuse tables in Appendix C

for continuous AC output power ratings.

5. Verify that the selected PowerFlex 755TL/TR AC drive is capable of precharging the connected inverter/drive DC bus capacitance. See the

tables in Appendix A

and Appendix C for internal and maximum external DC bus capacitance values. It may be necessary to increase the

rating of the PowerFlex 755TL/TR AC drive.

6. Verify that the interconnecting DC bus cables or bus bars are adequate for the expected DC bus current to each inverter/drive. Use the tables

in Appendix A

to determine the inverter/drive rated DC input currents.

Example Basic Sizing of the PowerFlex 755TL/TR AC Drive

This example represents a 480V AC input system with three motors and drives. The acceleration and deceleration times are assumed to be less

than one minute so we can take advantage of the overload duty of the inverter drives and the bus supply.

Bold text in the tables represents calculated values based on the calculation methods described earlier.

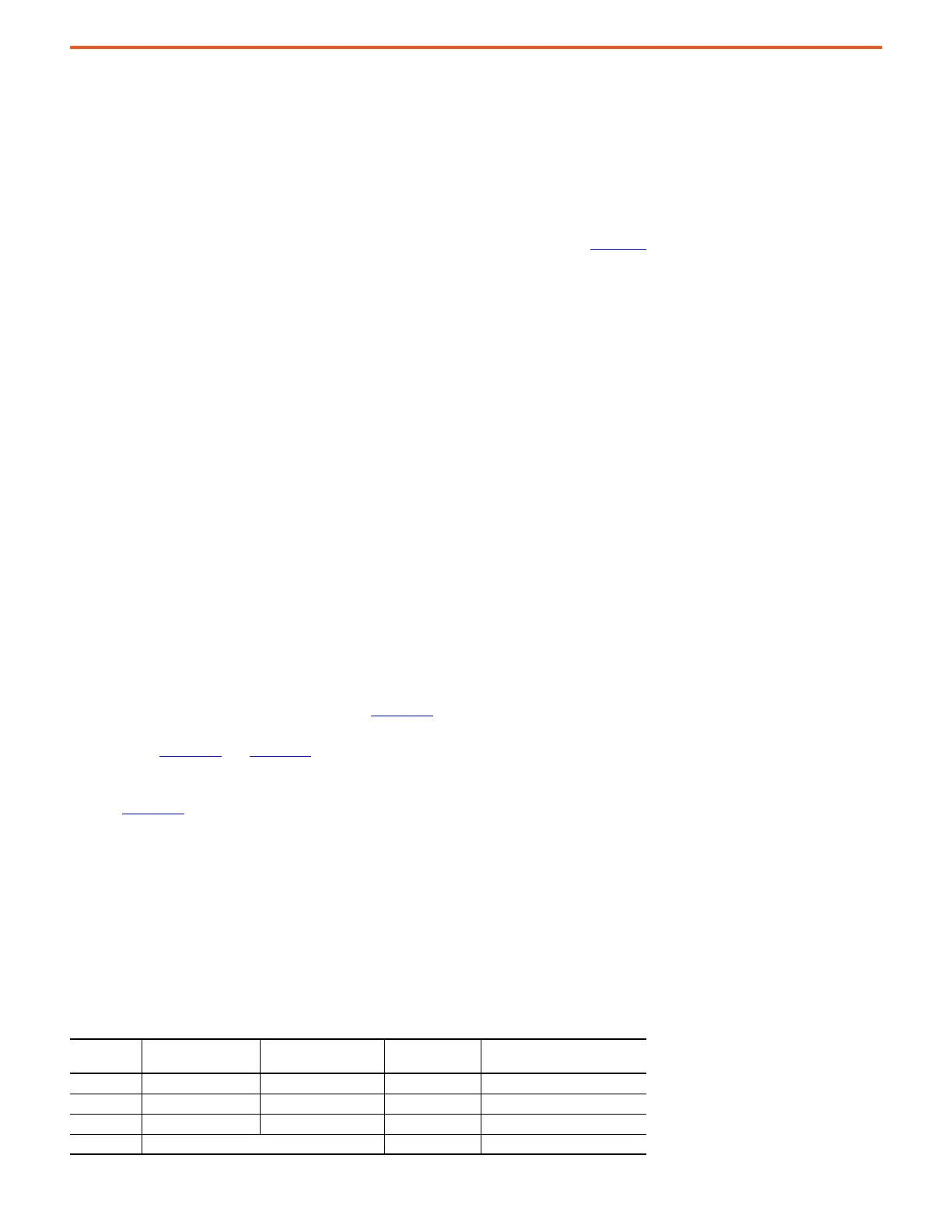

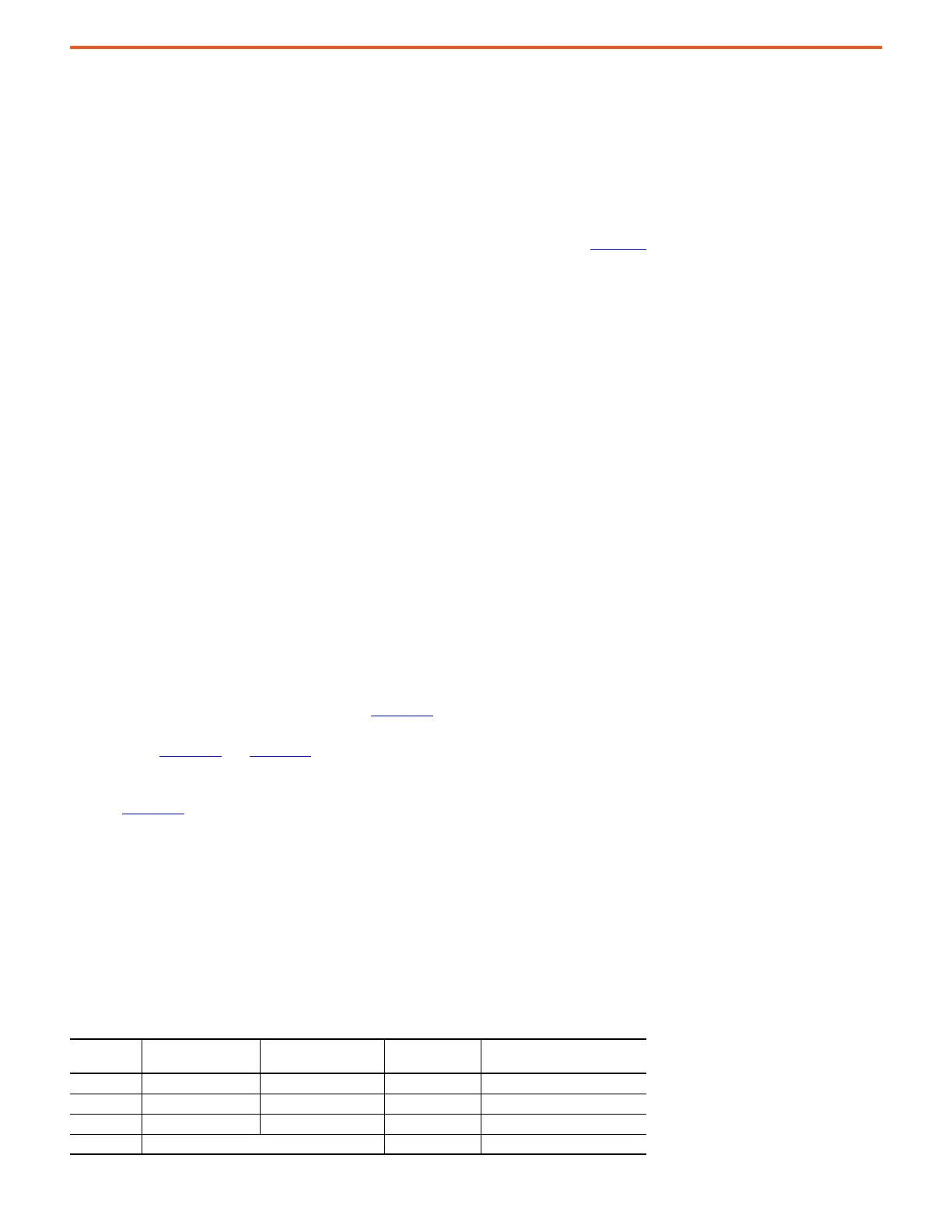

Steps 1…3 are summarized in the following table.

Section

Name

Motor Nameplate

Power (kW)

Motor Nameplate

Efficiency

Drive Output

Power (kW) Notes

Motor 1 11 0.9 12.2 Heavy Duty (HD)

Motor 2 45 0.85 52.9 Heavy Duty (HD)

Motor 3 5 0.92 5.4 Heavy Duty (HD)

Minimum Rated Output Power 70.6 Heavy Duty (HD)

Loading...

Loading...