16.2 Periodical Checks

In order to guarantee proper operation of the device we recommend checking on a regular basis

the parts that are the most subject to wear.

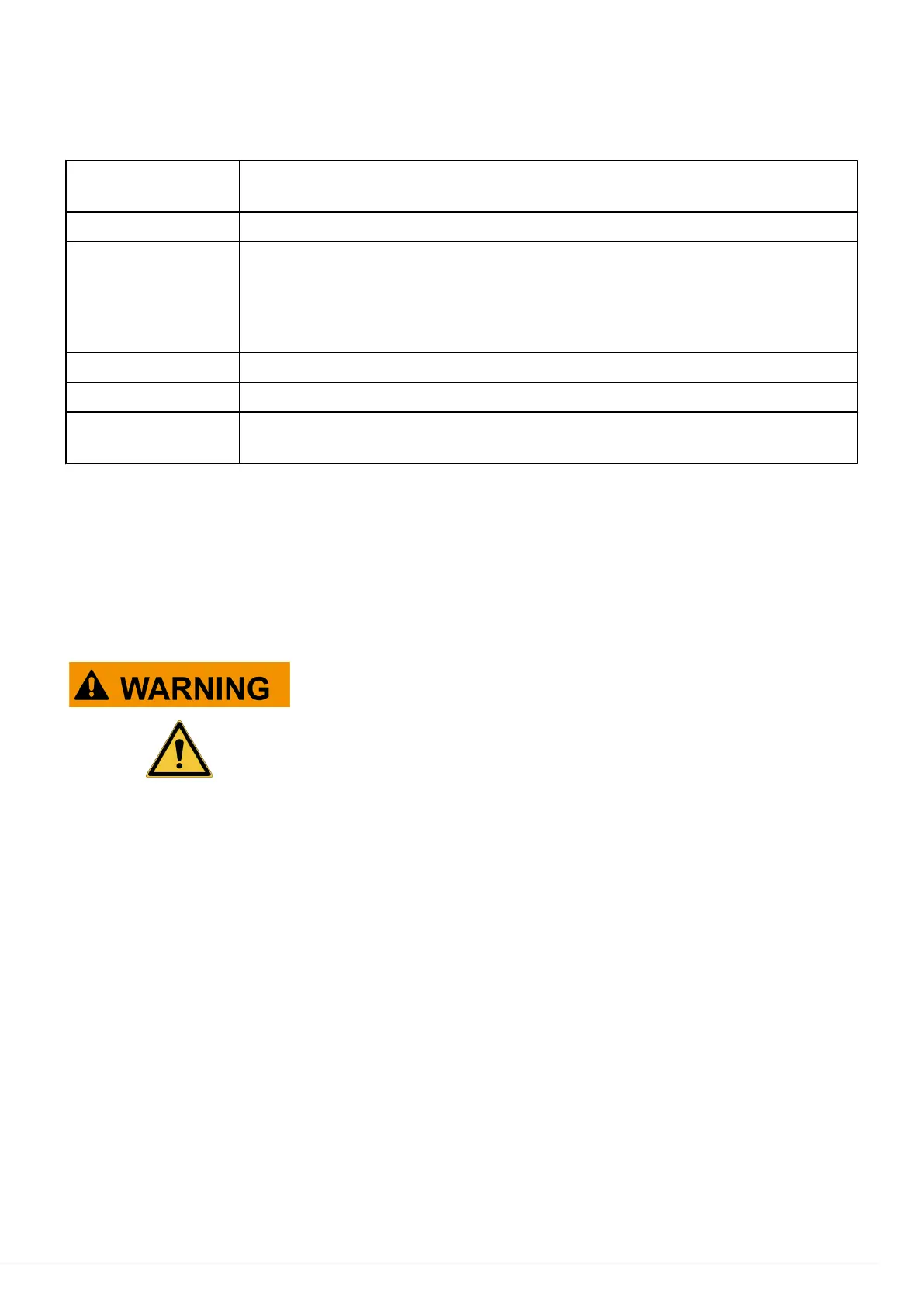

Parts subject to

wear

Check

Service hoses Make sure there are no cuts, scratches or bulges.

Quick fittings

Make sure there are no signs of wear and that the hoses do not harden

during use.

Make sure the service hoses are connected properly.

Make sure there are no cuts or scratches on the O-rings.

Oil and UV bottles Make sure they are clear and not damaged.

Wheels Make sure the brakes are working properly.

Power supply

cable

Make sure there are no cuts, scratches or burns.

16.3 Periodical Safety Checks

In order to guarantee the correct operation of the equipment, carry out periodical checks on the

safety devices and on the liquid refrigerant receiver.

The safety valve and safety pressure switch must be visually checked to verify that they are not

damaged in order to guarantee that they are working properly.

The liquid refrigerant receiver has its manufacturing and validity dates (5 years) printed on its collar.

A periodic inspection of the operation of the safety devices

(Safety Pressure Switch and Safety Valve) and of the integrity of

the refrigerant liquid receiver must be carried out at intervals

defined by the national regulations in force in the country in

which the equipment is being used.

49

Loading...

Loading...