PROCEDURE

FOR

SETTING

IDLING

SPEED

AND

CO%

*

If

the engine performance is good, the pilot

screw

I Volume control screw (VCS) need

not be disturbed.

* The idling speed can be adjusted only with

the idling screw.

* If there is a performance deterioration,

clean carburetor and adjust the idling

speed.

NOTE:

Before adjusting the idling speed, correct the free

play of cable assembly throttle to 1-2mm.

ADJUST THE IDLING SPEED

AS

FOLLOWS:

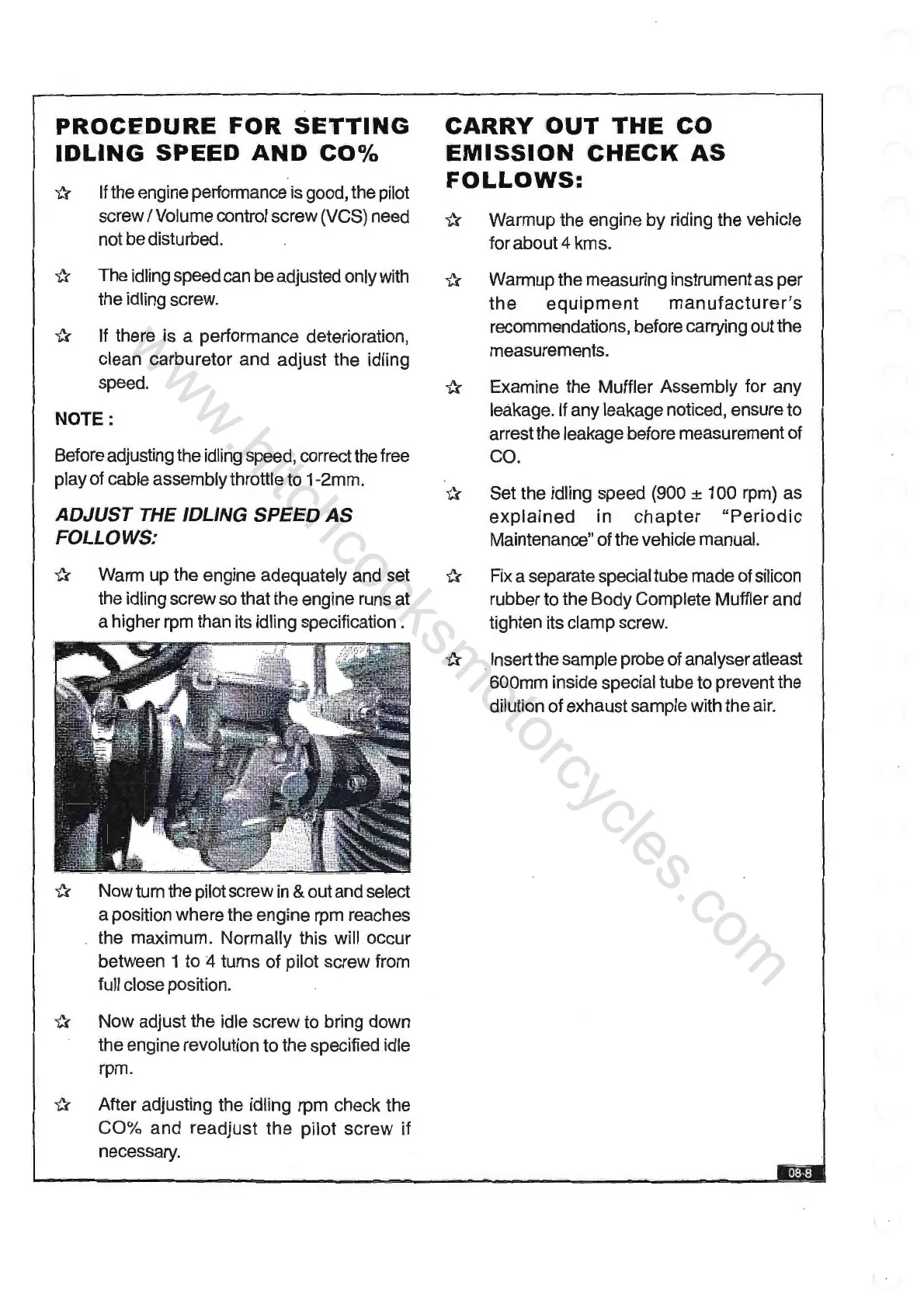

* Warm up the engine adequately and set

the idling screw

so

that the engine runs at

a higher rpm than its idling specification .

* Now turn the pilot screw

in

& out and select

a position where the eng;ne rpm reaches

the maximum. Normally this will occur

between 1 to 4 turns of pilot screw from

full close position.

* Now adjust the idle screw to bring down

the engine revolution to the specified idle

rpm.

* After adjusting the idling rpm check the

CO%

and

readjust

the

pilot

screw

if

necessary.

CARRY

OUT

THE

CO

EMISSION

CHECK

AS

FOLLOWS:

* Warmup the engine by riding the vehicle

for about 4 kms.

* Warmup the measuring instrument as per

the

equipment

manufacturer's

recommendations, before carrying out the

measurements.

* Examine the Muffler Assembly for

any

leakage. If any leakage noticed, ensure to

arrest the leakage before measurement of

co.

* Set the idling speed (900 ± 100 rpm) as

explained

in

chapter

"Periodic

Maintenance" of the vehicle manual.

* Fix a separate special tube made of silicon

rubber to the Body Complete Muffler and

tighten its clamp screw.

* . Insert the sample probe of analyser atleast

600mm inside special tube to prevent the

dilution of exhaust sample with the air.

www.hitchcocksmotorcycles.com

Loading...

Loading...