14 M0412-1 ver 3.0

3 MAINTENANCE AND SERVICE

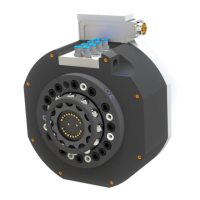

The swivel tool changers and the tool attachments must be maintained regularly to ensure

proper function. The specified intervals are approximate and valid under normal conditions,

corresponding to 2 tool changes per minute during 2 work shifts per working day, i.e. 42.000 tool

changes per month. Under extreme conditions, such as dirty environments or extreme robot

movements, the intervals should be shortened. Consider the table as a guide and update as

your production experience of each system increases.

NOTE!

Read the safety section 1.2.before any maintenance activities are carried out.

NOTE!

Swivel tool changers must only be dismantled and repaired by Robot System

Products during the warranty period. Otherwise the warranty will not be valid.

3.3 Maintenance scheme

3.3.1 Every second week

The following maintenance activities should be carried out every second week.

Visual inspection of swivel tool changer,

rotation stop and cables (section 3.4.1).

Check locking balls (section 3.4.1).

Check air sealings (section 3.4.1).

Check spring-loaded signal pins (section

3.4.1).

Visual inspection of tool attachment and

cables (section 3.4.2).

Clean contact surfaces (section 3.4.2).

3.3.2 Every six-months or 250,000 tool changes

The following maintenance activities should be carried out every six-months or 250,000 tool changes.

Clean locking balls and add new

lubrication, (section 3.4.3).

Clean air sealings (section 3.4.3).

Spring-loaded pins

(electrical versions

only)

Clean spring-loaded signal pins (section

3.4.3).

Clean the cavities of the locking balls.

(section 3.4.4).

Clean the contact surfaces of air

sealings (section 3.4.4).

Loading...

Loading...