21

COMPILER TECO/ATI ENDORSEDDATE

01.08.2003

REG. CODE

1-5302-620

MODEL N°

50902

DATE OF ISSUE

08-03

REVISION 00

X

17

18

19

0,30 ÷ 0,50

0,25 ÷ 0,50

0,80

0,80

A = 0,22

B -C= 0,18

D = 0,16

0,001 ÷ 0,010 0,060

RD210 RD 211

RD270 RD278

89,919 ÷ 89,930

94,920 ÷ 94,935

CHECKS AND OVERHAUL

Piston rings - Pistons - Piston pins

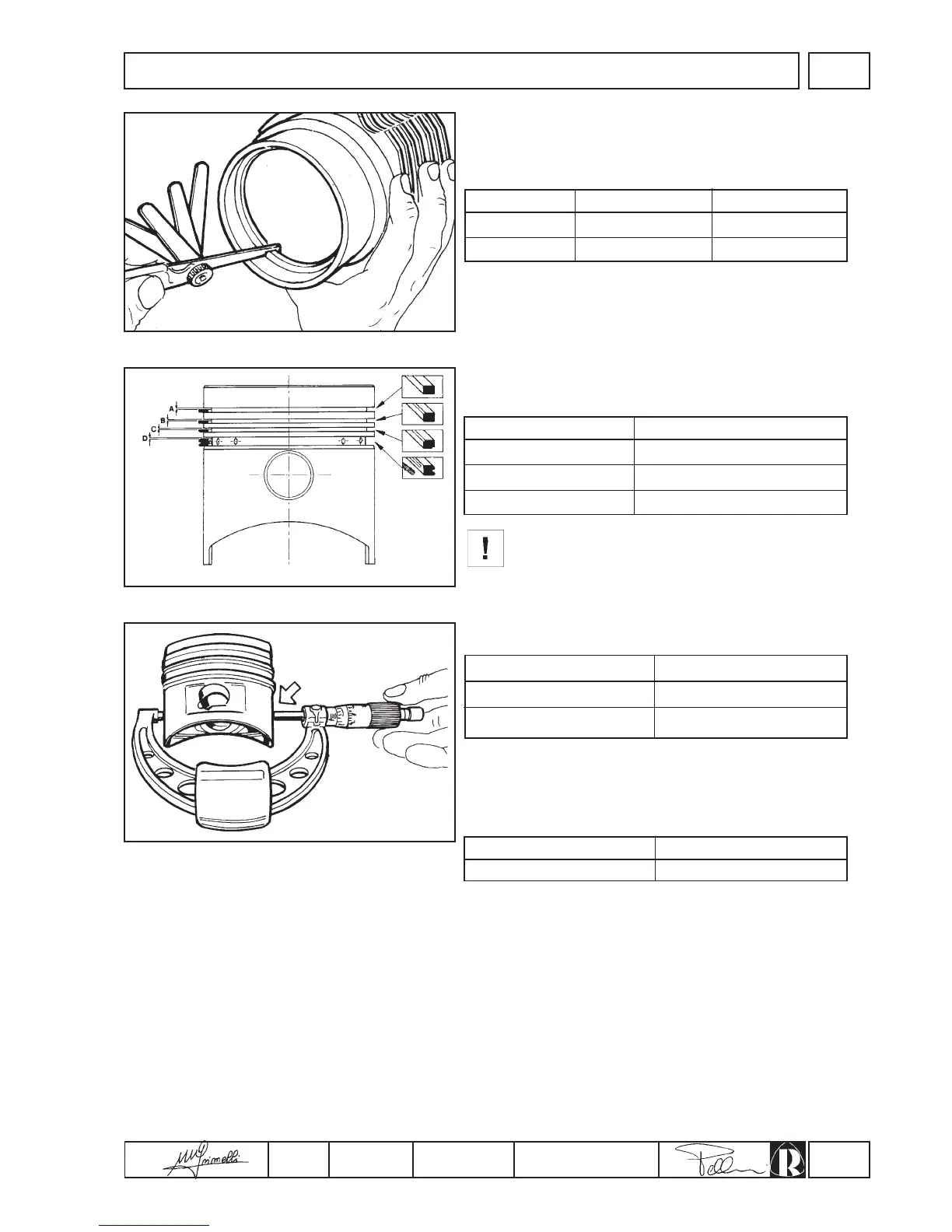

Check the wear of piston rings by fitting them into the cylinder

through the lower end and measuring the end gap (fig.17). The

values should be:

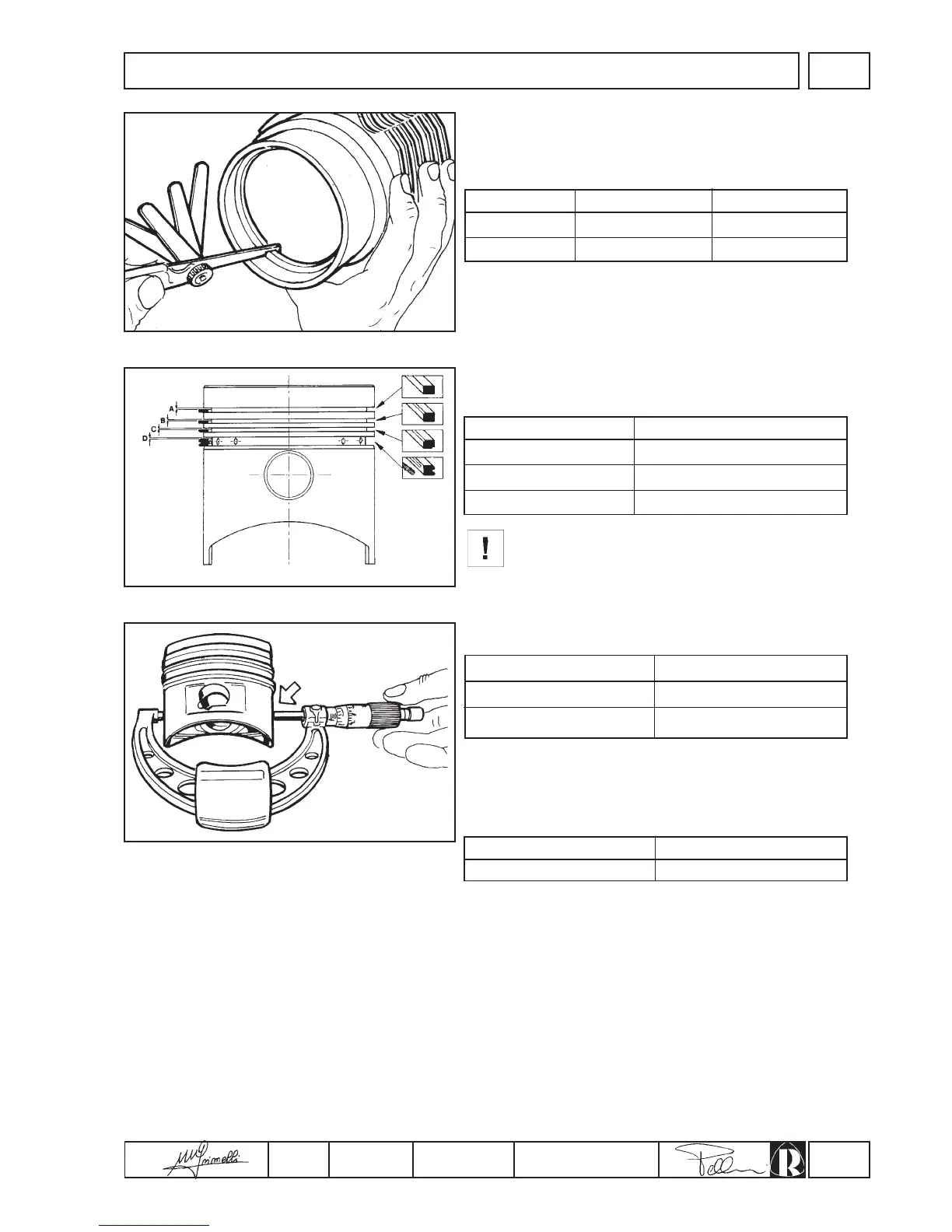

Check that the rings move freely in the grooves and check the ring/

groove clearance using a feeler gauge (fig.18).

If the clearance exceeds the values shown in the table, renew the

piston and the piston rings.

Piston rings must always be renewed after dismantling

the piston.

Piston diameter check: The diameter of the piston must be

measured at approximately 18 mm from the base (fig.19).

Fitting mm Max. wear mm

Piston ring

1st Compression

2nd- 3rd Compression

4th Oil scrapper

Max. wear mm

Engine

Diameter mm

Fitting mm Max. wear mm

Piston ring

Compression

Oil scrapper

Check the clearance between cylinder and piston, if it is greater

than 0.120 mm both cylinder and piston must be replaced.

Assembly clearance between piston pin and piston in millimetres:

Loading...

Loading...