32

COMPILER TECO/ATI ENDORSEDDATE

01.08.2003

REG. CODE

1-5302-620

MODEL N°

50902

DATE OF ISSUE

08-03

REVISION 00

49

50

51

52

XII ENGINE ASSEMBLY

Notice: These instructions are valid for engines up-dated

prior to the publication of this manual. Any modifications

must be checked on the technical circulars.

Before assembling the engine carefully clean all parts

and dry them with compressed air. Lubricate moving parts

to prevent seizing when starting up. Replace the gaskets

with new ones each time the engine is assembled.

Use torque wrenches to ensure that the correct tightening

torques are applied.

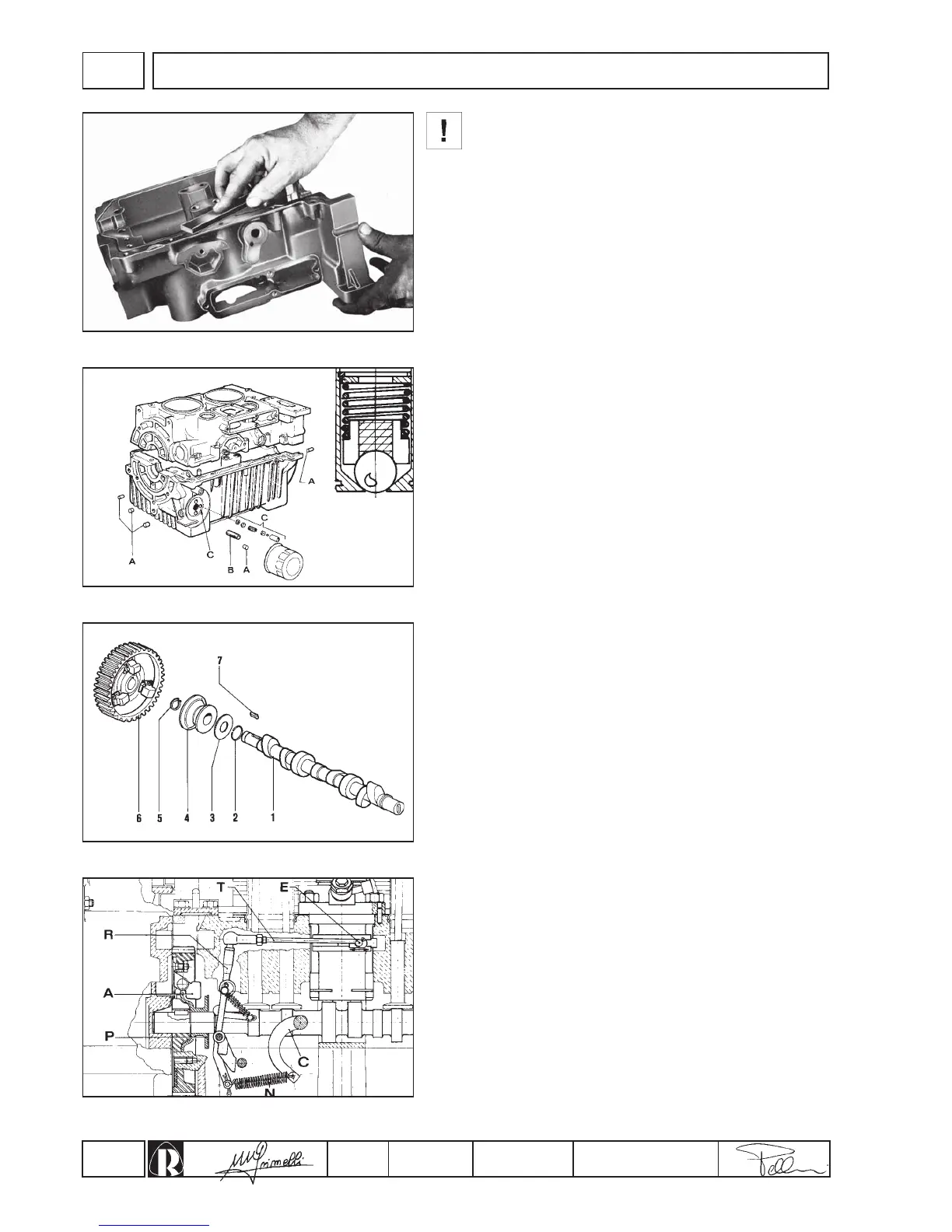

Preparation of crankcase

Clean support faces and remove seal residue and dirt with a

copper plate or a fine emery stone to avoid damage to the contact

surfaces (fig. 49).

Lower crankcase (fig. 50)

1.Insert plugs (A) into relative seats.

2.Screw in oil filter cartridge connection (B). The connection

should protude 11 to 13 mm. from the crankcase.

3.Insert complete oil pressure register valve into its seat (C).

Make sure the seat of the valve ball in the casing is free of dirt or

scores which could jeopardize the pressure seal.

4.Insert cylinder studs and centering pins.

Camshaft preparation

To prepare the camshaft unit (fig. 51) proceed as follows:

1.Insert shim adjustment washer (No 3) and governor plate

(No 4) on camshaft.

2.Fit snap ring (No 5) and tab (No 7) into respective housings.

3.Heat gear (No 6) complete with masses and insert onto

camshaft making sure it rests against the locking snap ring.

4.Insert governor plate locking ring (No 2).

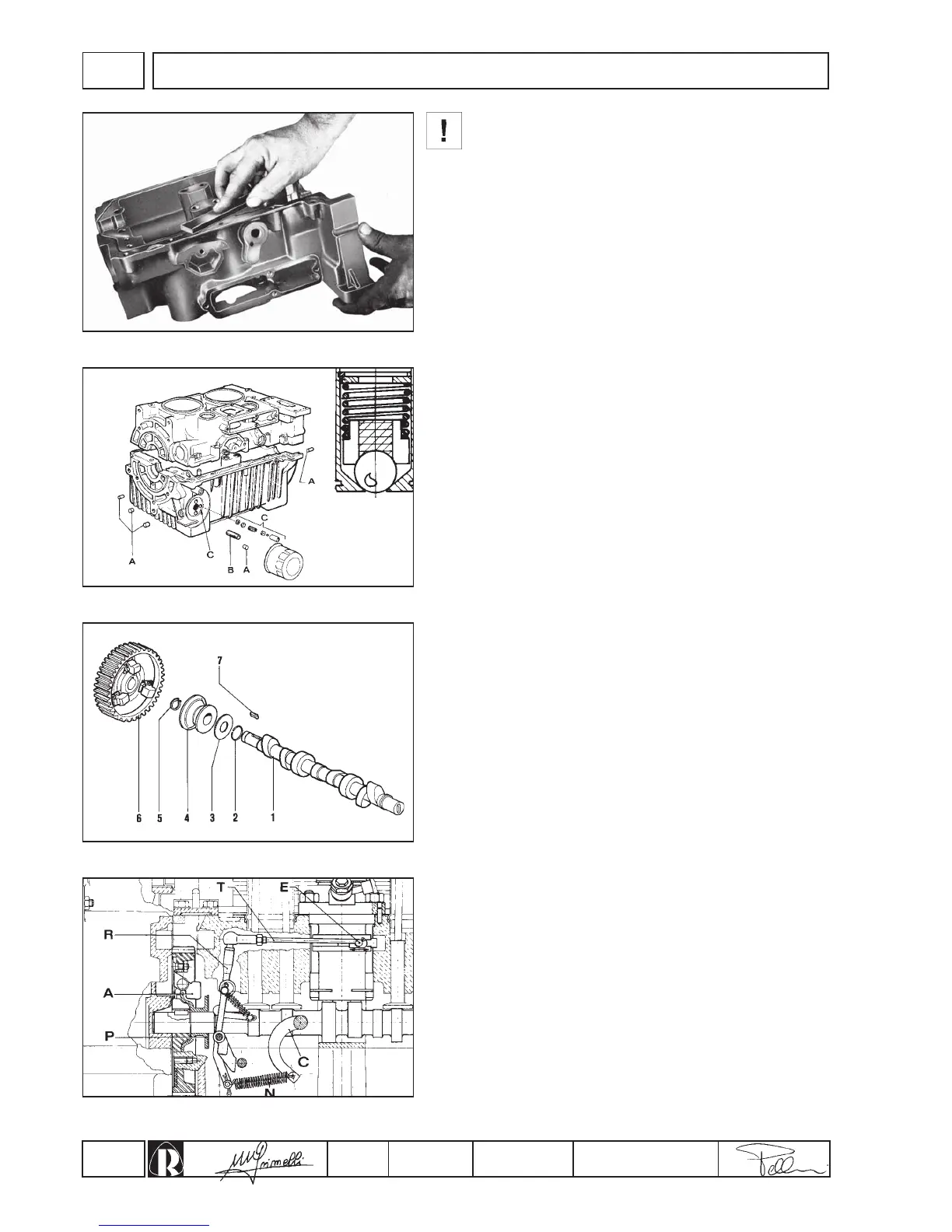

The speed governor is of the centrifugal mass type splined

directly onto the ends of the camshaft gear (fig. 52).

Masses (A), pushed outwards by the centrifugal force, shift mobile

plate (P) axially. Said plate actions lever (R) connected to injection

pump rack bar (E) by means of tie rod (T).

A spring (N) placed under tension by the accelerator (C), contrasts

the action of the centrifugal force of the governor.

The balance between the two forces keeps the revolutions

practically constant when load is changed.

For pre-load adjustment of the speed governor see paragraph on

page 40 "Injection pump tie rod connection".

Loading...

Loading...