38

COMPILER TECO/ATI ENDORSEDDATE

01.08.2003

REG. CODE

1-5302-620

MODEL N°

50902

DATE OF ISSUE

08-03

REVISION 00

72

73

74

75

XIII

0,25 ÷ 0,35 mm

0,9 ÷ 1,1 1,8

RD210 RD 211 2,25 ÷ 2,75

RD270 RD278 3,75 ÷ 4,25

mm

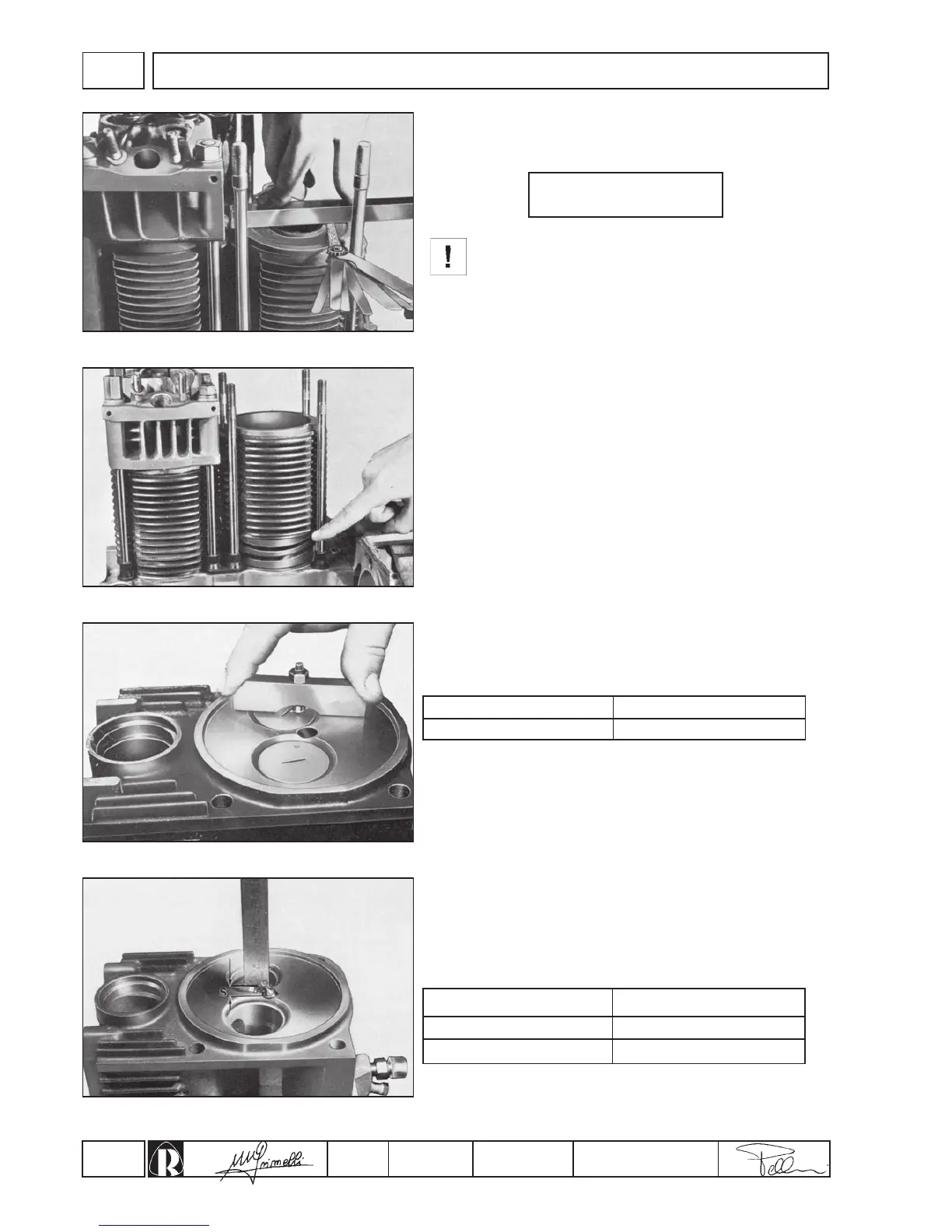

In order to carry out this operation correctly, make the

check with the cylinder pressed well down on its

crankcase (fig. 72).

The clearance is adjusted by means of shims inserted between the

lower face of the cylinder and crankcase (fig. 73).

Shim dimensions: 0.1 to 0.2 mm

Cylinder height adjustement

Between the top face of the cylinder and the piston at top dead

center, there must be a clearance of:

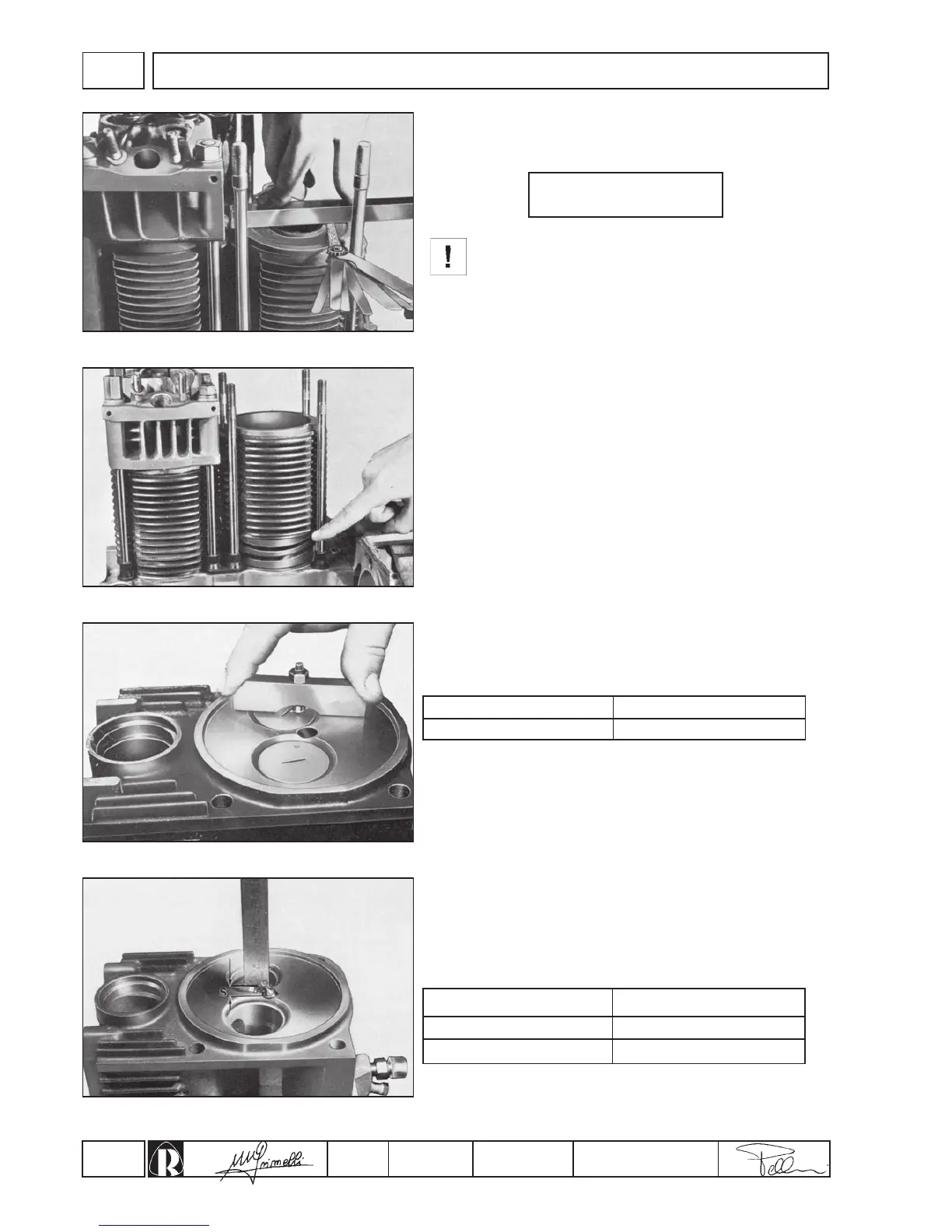

Checking valve head face depth

When replacing valves check that the clearance from the top of the

head to the face (fig. 74) is of:

For different values see on pages 18-19.

Checking injector protrusion

Before mounting the heads on the cylinders, insert injectors in their

housings and after having secured them temporarily, check

protusion of nozzles from head surface (fig. 75).

Protusion S should be:

Fitting mm Max. wear mm

ENGINE ASSEMBLY

Engine

Loading...

Loading...