24

COMPILER TECO/ATI ENDORSEDDATE

01.08.2003

REG. CODE

1-5302-620

MODEL N°

50902

DATE OF ISSUE

08-03

REVISION 00

X

27

28

29

0,015 ÷ 0,048 0,100

0,10

11,98 ÷ 11,99

12,00 ÷ 12,018

28,3028,39÷ 28,43A

RD210-211

RD270-278

29,70

30,25

29,95 ÷ 30,00

30,52 ÷ 30,57

A-B

A-B

RD210-211-270-278

exhaust inlet

Fitting mm Max. wear mm

Engine

Measurement

Fitting

mm

Max. wear

mm

Engine

Measurement

Fitting

mm

Max. wear

mm

Max .assy.clearance mm

Fitting mm

CHECKS AND OVERHAUL

Oil seal rings

Make sure the oil seals have not hardened round the internal

contact edge with the crankshaft and that they do not show signs of

cracks or wear. If they do, replace them with new ones of the same

size.

Then re-fitting the oil seal, use protective cone cod.

00365R0260. Fit said cone over the ends of the crankshaft

to avoid damage to the ring itself.

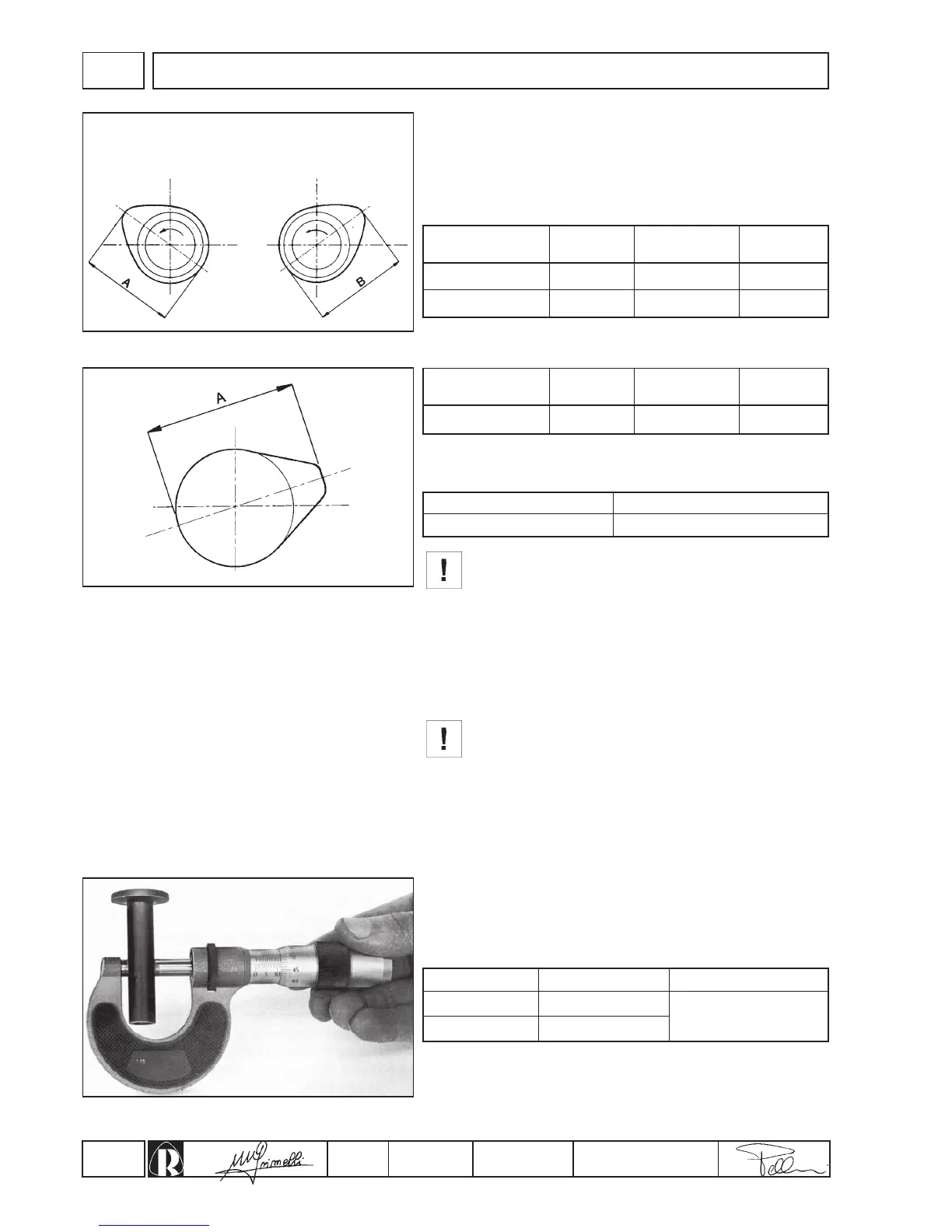

Tappet checking

Make sure the tappet surfaces are not worn, lined or present signs

of seizure. If so, replace.

Tappet and seat check in mm (fig. 29).

Measurement

Tappet

Tappet seat

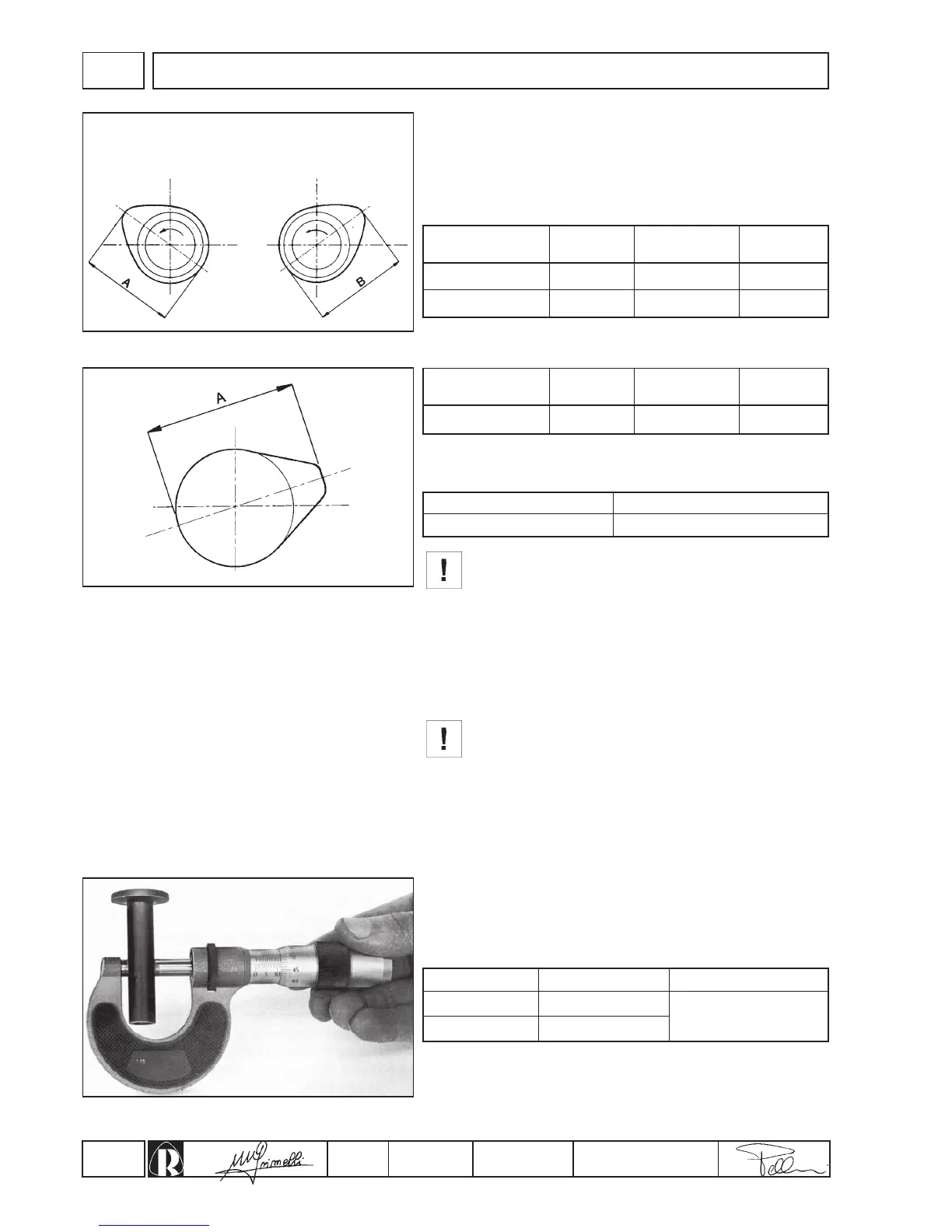

Camshaft

Check cams and support pins for wear or scores.

Check amount of wear by measuring points A and B shown in fig.

27 and 28 and comparing to the figures of the tables hereunder:

Distribution cam dimensions (fig. 27).

Injection cam dimensions (fig. 28)

The coupling clearance between pins and respective housings

should be:

Renew the camshaft if the cams or journals show wear in

excess of 0.1mm.

Loading...

Loading...