42

COMPILER TECO/ATI ENDORSEDDATE

01.08.2003

REG. CODE

1-5302-620

MODEL N°

50902

DATE OF ISSUE

08-03

REVISION 00

XIV

90

89

88

91

0,15 mm

intake/exhaust

ENGINE TESTING

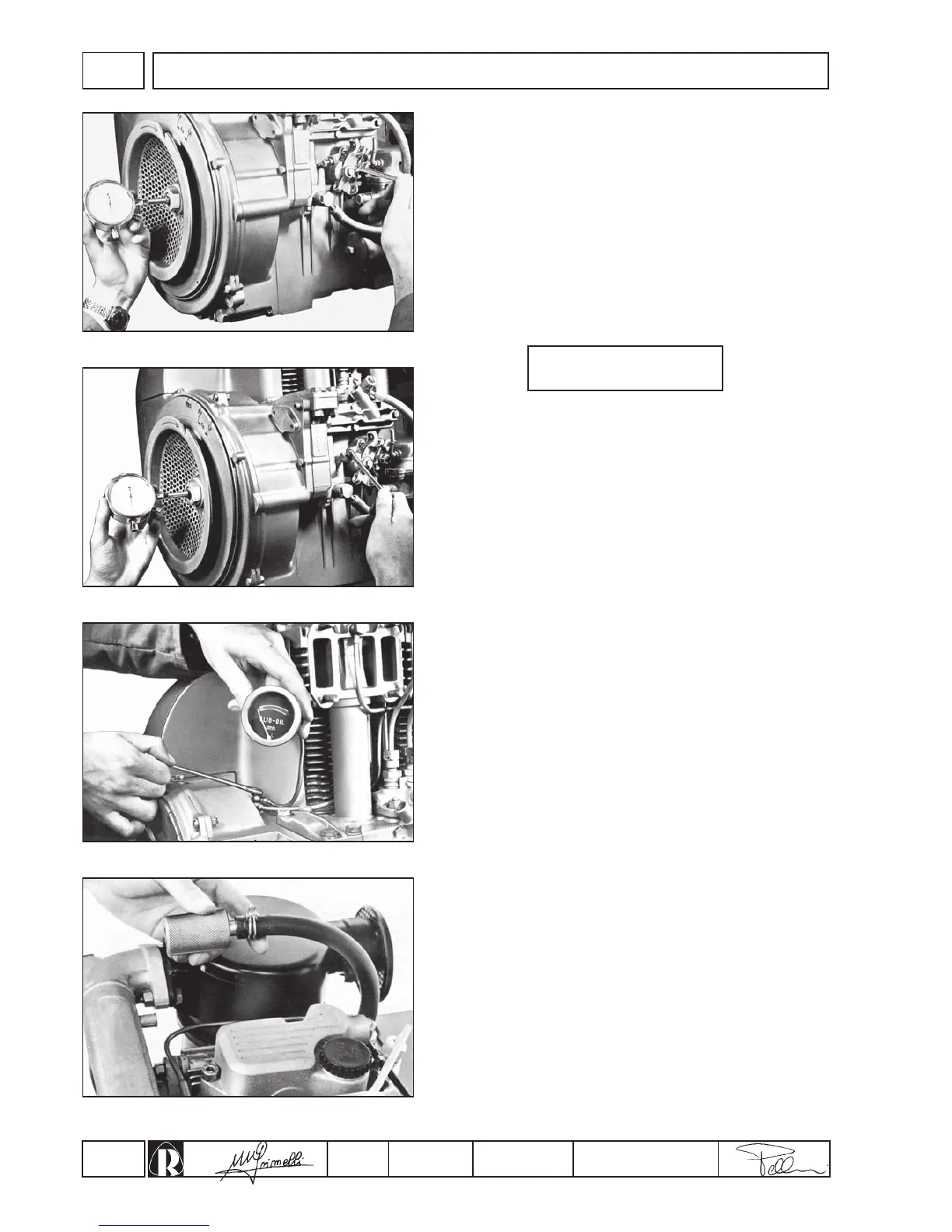

Checking oil pressure

1.Remove union from rocker oil hole and fit a pressure gauge

graded from 0 to 8 kg/cm² (fig. 90).

2.Start engine and run up to 3000 RPM. Wait for the oil

temperature to reach 70 to 80°C.

3.With engine idling at 3000 RPM the pressure gauge needle

should be slightly over half way corresponding to a pressure of

3 to 4 kg/cm².

Said pressure will stabilize at 2 to 3 kg/cm² when engine runs

at full load and the oil temperature exceeds 70 to 80°C.

4.Reduce revs to minimum. The pressure should not fall to under

1 kg/cm² with the oil temperature exceeding 80°C.

Checking for oil leaks

1.Remove exhaust gas collection pipe from suction manifold and

close with a plug (fig. 91).

2.Start engine and run for a few minutes. The pressure which

forms inside the crankcase bring out any oil leaks.

3.Re-fit gas collection pipe to suction manifold.

5.Re-fit rocker covers and sealing gaskets.

Speed adjustment

1.With engine hot set minimum speed at 1000 RPM (fig. 88) and

maximum to idle (fig. 89) at:

2100 RPM for RD 278 engine

3150 RPM for RD 210 engines

3700 to 3750 RPM for RD 211 engines

2.Then stop the engine.

3.Remove injectors, clean nozzle holes carefully, check setting

and re-fit.

4.Adjust clearance between valves and rockers, while engine is

hot, to:

Loading...

Loading...