40

COMPILER TECO/ATI ENDORSEDDATE

01.08.2003

REG. CODE

1-5302-620

MODEL N°

50902

DATE OF ISSUE

08-03

REVISION 00

82

81

XIII

80

83

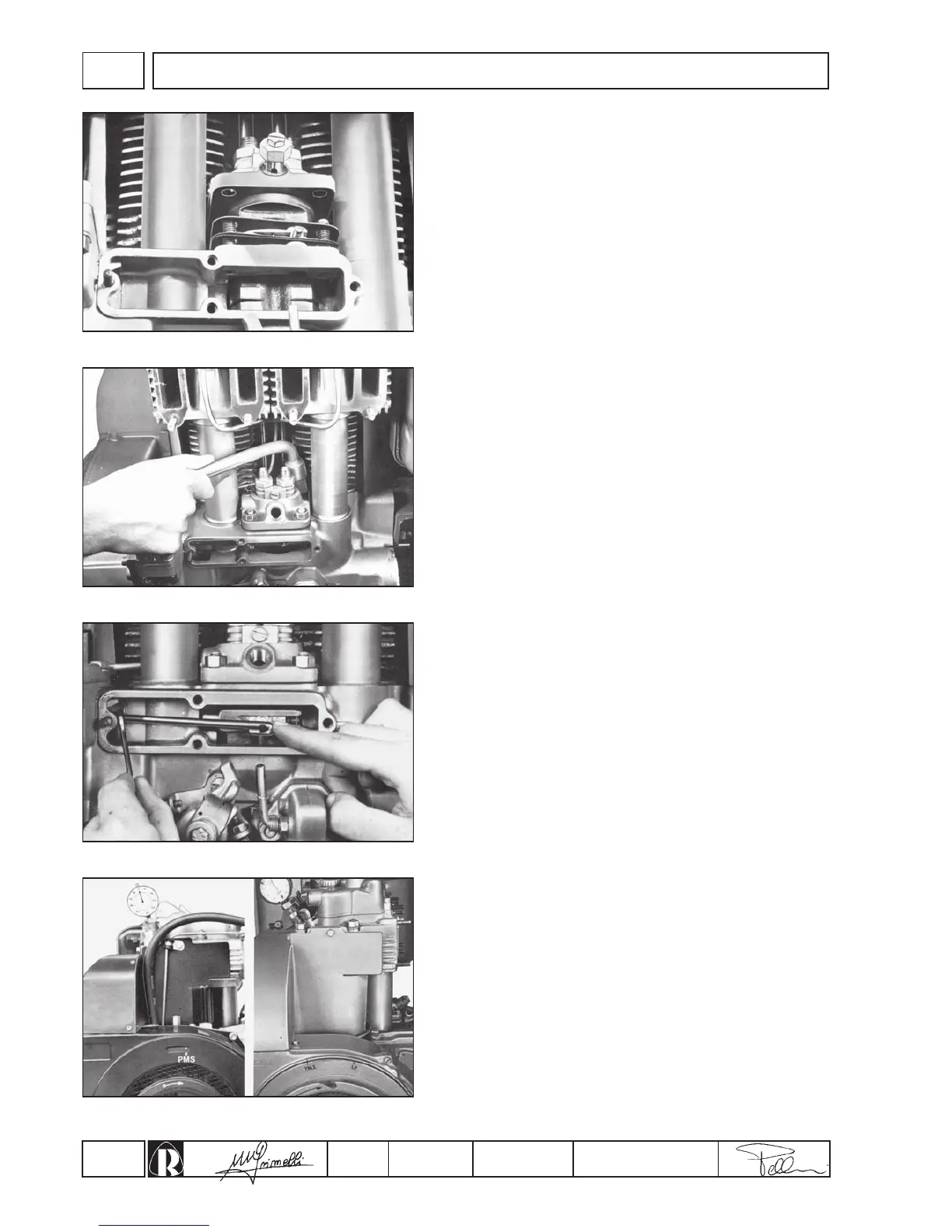

Injection pump fitting

Fit injection pump into timing case inserting adjusting shim

between supporting flange and crankcase (fig. 80).

To facilitate the insertion of the pump, rotate the flywheel so as to

bring the actuating cam to rest position and set the rack bar in a half

way position.

To facilitate tightening of pump nuts on the cylinder side, use the

special key (tool od. 00365R0210) illustrated in fig. 81.

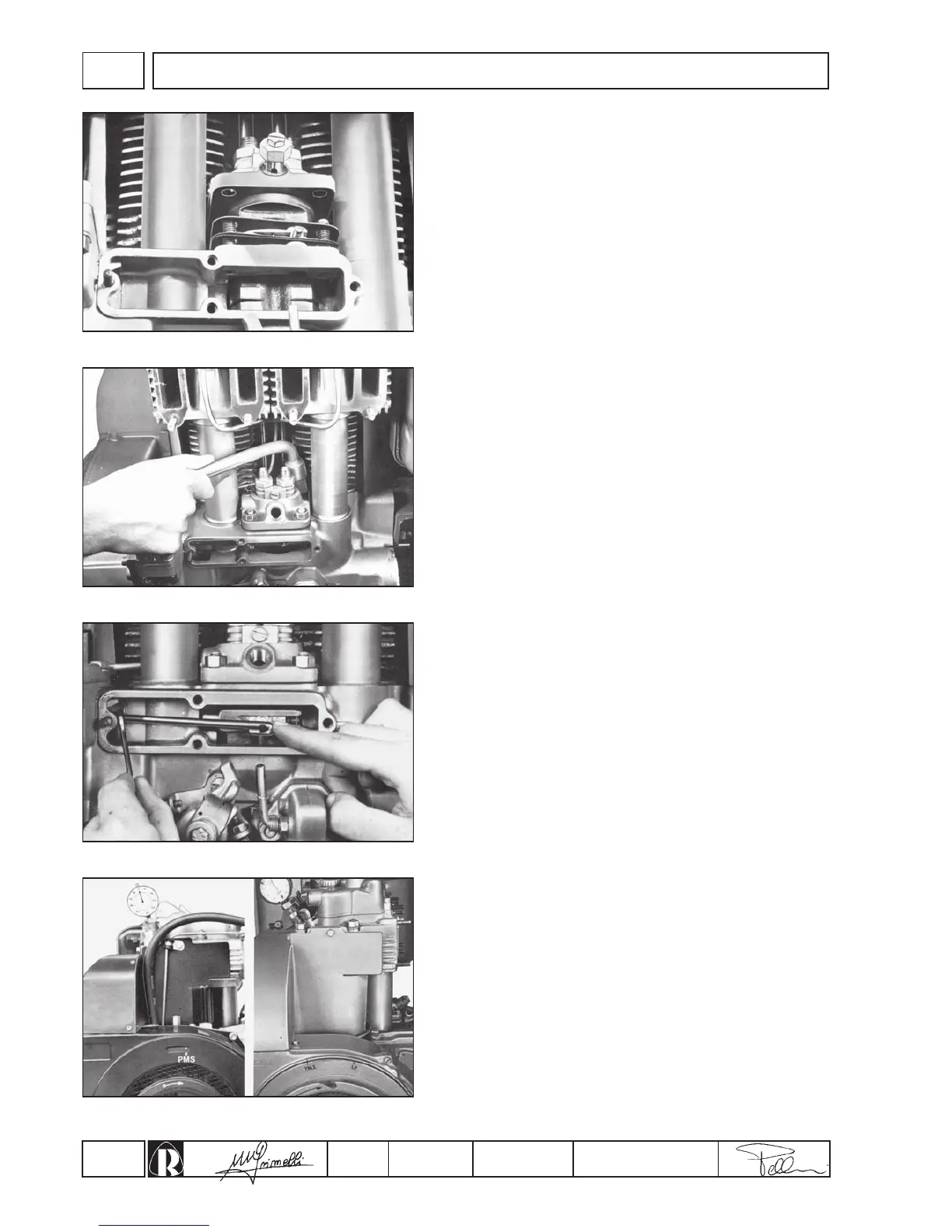

Injection pump tie rod connection

- The injection pump tie rod length, measured from the

connecting centre of the rack bar to the centre of the ball joint

must be mm 118 ±1 complete turn.

Careful operation will avoid uneven running, starting difficulties

and power losses.

- Connect tie rod to governor lever, engaging the ball joint to 90°

(fig. 82), and to the injection pump rack bar and then insert split

pin.

Checking T.D.C.

With pistons in respective top dead center compression position

check that the arrows on the air conveyor coincide with top dead

center position indications on the flywheel (fig. 83).

If the flywheel has to be replaced, transfer and punch the above

mentioned indications on the new one.

ENGINE ASSEMBLY

Loading...

Loading...