28

COMPILER TECO/ATI ENDORSEDDATE

01.08.2003

REG. CODE

1-5302-620

MODEL N°

50902

DATE OF ISSUE

08-03

REVISION 00

XI

40

41

42

43

5 kgm (49 Nm)

RD210 RD 211 RD270 RD278

A B

RD210 RD 211 0,25

RD270 RD278 0,28

RD210 RD 211 225 ÷ 235

RD270 RD278 220 ÷ 230

Engine

Engine

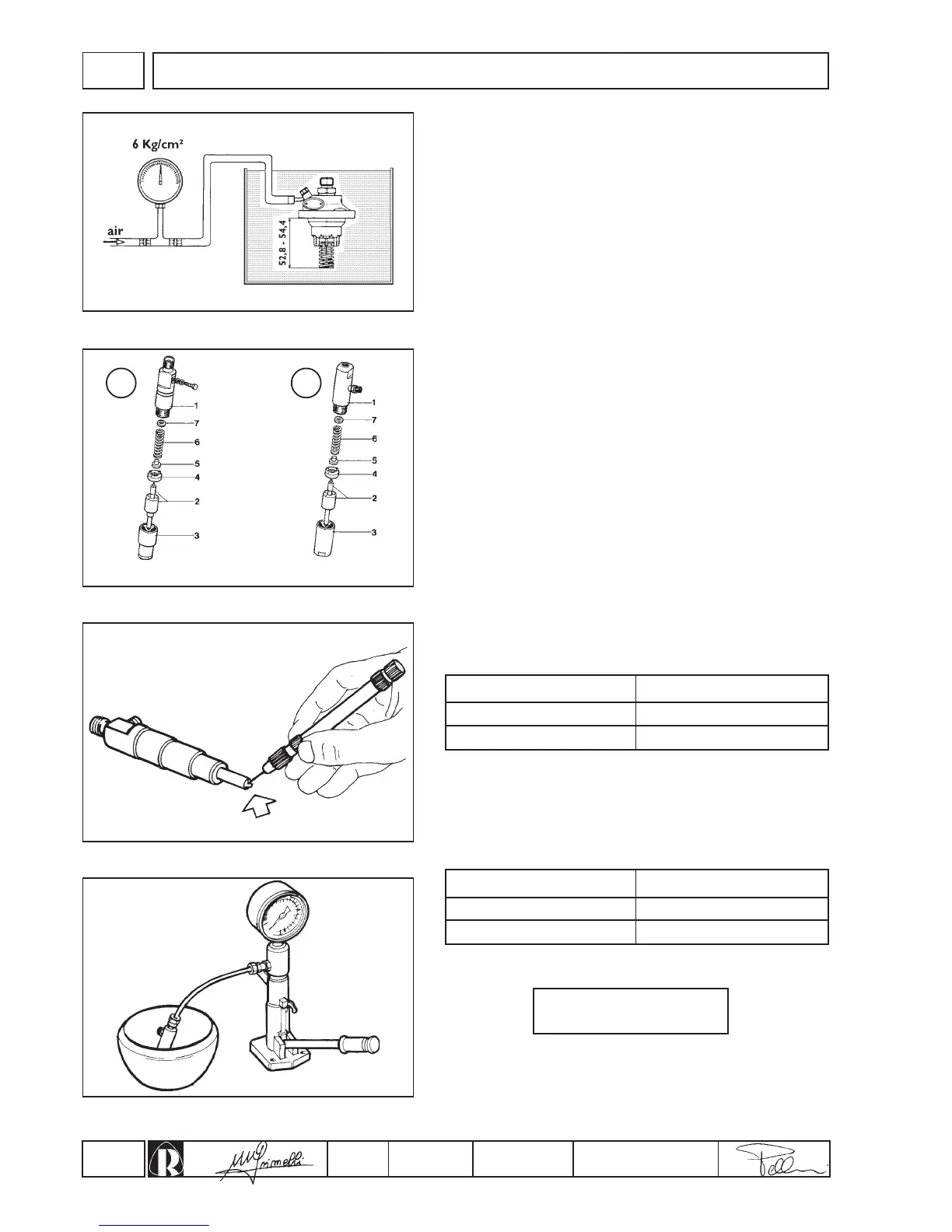

Testing air tightness

Feed pressurized air at 6 kg/cm² into the fuel sullpy union and

completely immerse the pump in oil or diesel fuel for about 20 ÷ 30

seconds (fig.40); check that no air bubbles are released.

N.B.: Tightness can be checked by compressing the springs to

52.8 ÷ 54.4 mm, which corresponds to the bottom dead centre

working position of the pump.

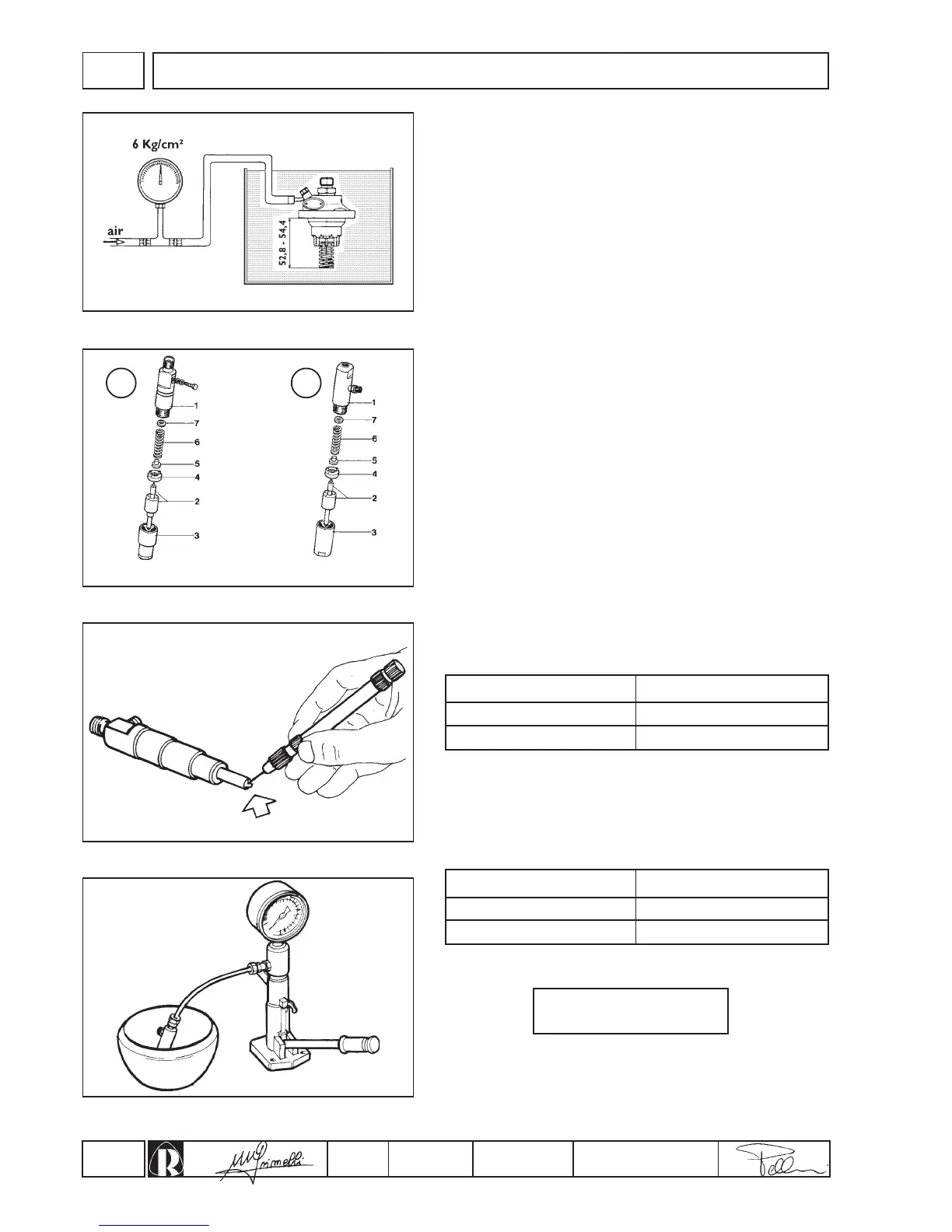

Injector checking and setting

1.Clean out nozzle holes with a thin piece of wire (fig. 42) of the

same size as that of the nozzle holes indicated on the table:

2.Set up injector on a test bench (tool cod. 00365R0430).

3. Unscrew injector lock coupling (No 3 fig. 41) or nozzle ring nut and

insert adjustment shim (7, fig. 41) until the pressure indicated in the

table hereunder is reached on the pressure gauge while pumping.

4.Tighten the nozzle ring nut (No 3 fig. 41) at:

5.When setting is complete, while still at the test bench, run

pumping elements a few times and check the amount of diesel

that passes through the upper leak-off of the injector (fig. 43).

Ø holes mm

Setting kg/cm

2

INJECTION EQUIPMENT

Injectors (fig. 41)

The engines can be equipped with three different types of injectors.

Type A injector for RD 210-211

1.Body - 2.Nozzle - 3.Ring nut - 4.Plate - 5.Rod - 6.Spring -

7.Adjustment shim.

Type B injector for RD 270-278

1.Body - 2.Nozzle - 3.Ring nut - 4.Plate - 5.Rod - 6.Spring -

7.Adjustment shim.

Loading...

Loading...