36

COMPILER TECO/ATI ENDORSEDDATE

01.08.2003

REG. CODE

1-5302-620

MODEL N°

50902

DATE OF ISSUE

08-03

REVISION 00

XIII

64

65

67

66

kgm 3,8 ÷ 4 (37,3 ÷ 39,3 Nm)

1,7 ÷ 2,1 mm

34 ÷ 34,2 mm

ENGINE ASSEMBLY

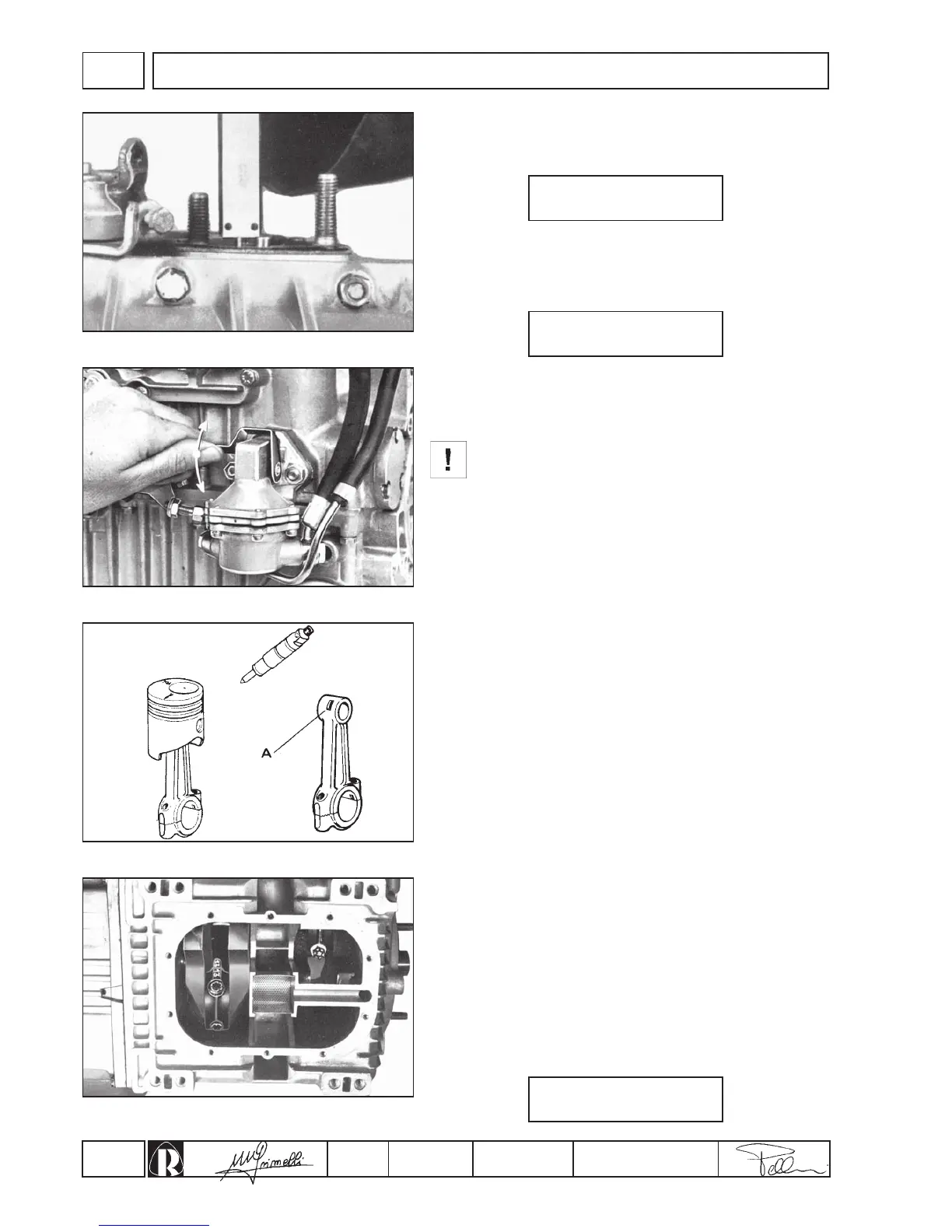

Feeding pump assembly

1.Insert fuel feeding pump cap into its housing and make sure it

moves freely. The length of the cap is :

4.With fuel feeding pump control cams at bottom dead centre

position mount feeding pump and action manually. There

should still be a small suction stroke (fig. 65).

If said checks are not carried out, the fuel feeding pump

diaphram could be damaged due to the excessive stroke

to which it will be subjected.

2.Fit gasket (0.5 mm and 0.2 mm thick).

3.With fuel pump control cams in a rest position the cap should

protude from the gasket surface (fig. 64) for:

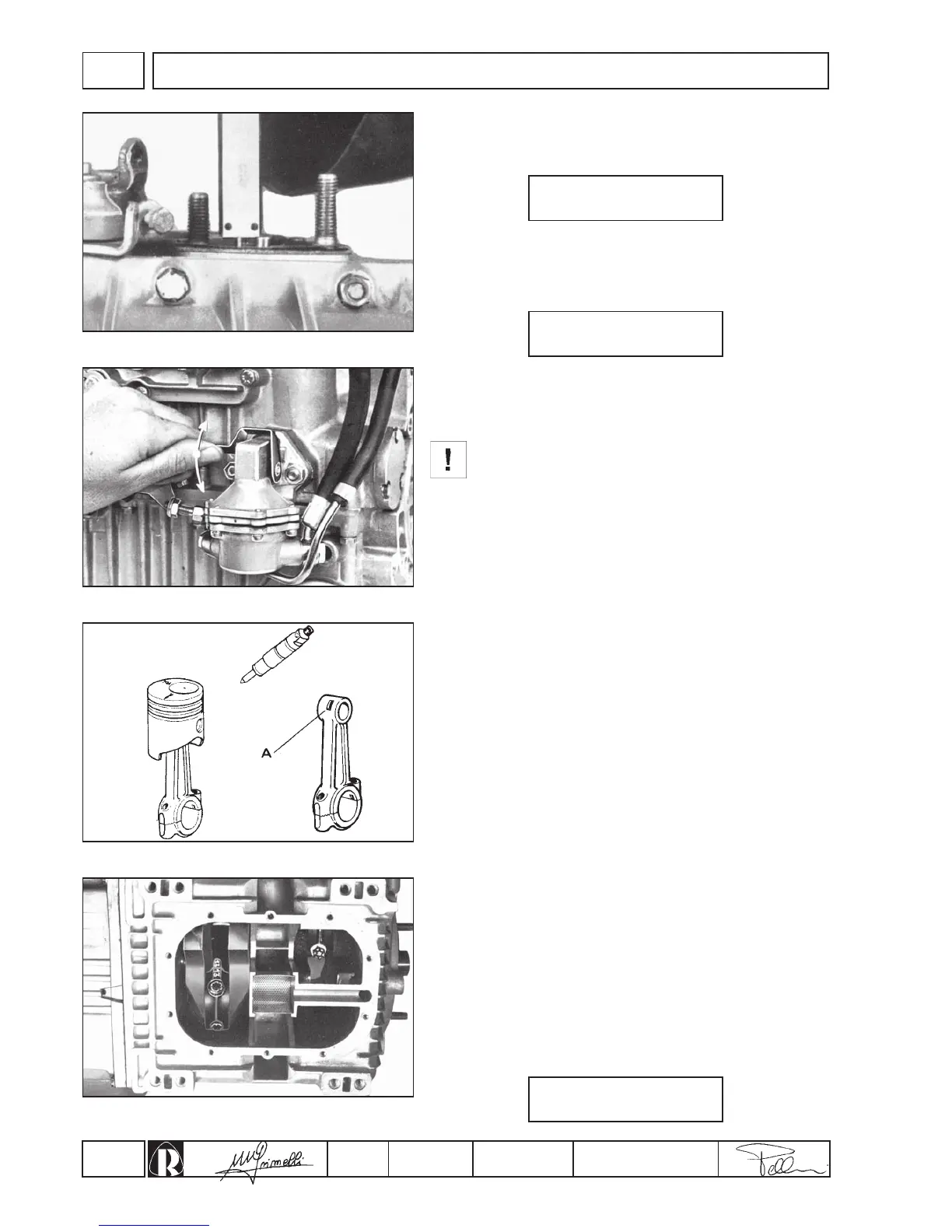

Piston-connection rod couplings

The piston is coupled to the connecting rod by means of slight hand

pressure on the gudgeon pin without heating the piston.

RD 210-211-218

The clearance between the small end and the gudgeon pin is:

0.023 to 0.038 mm and between gudgeon pin and piston: 0.002 to

0.008 mm.

The lubrication groove (A, fig. 66) on the small end must be turned

towards the engine rotation direction (injection pump side).

RD 220 - 240 - 270 - 278

The clearance between small end main bearing and gudgeon pin

is: 0.001 to 0.007 mm and between gudgeon pin and piston: 0,001

to 0,010 mm.

There is no specific position for mounting the connecting rod as the

lubrication groove is located inside the rod itself.

Connecting rod-crankshaft coupling

After insertion of the bearings into the big end, attach connecting

rods to crank pins, bearing in mind that an arrow, on the pistons for

RD210-211 , indicates the rotation direction of the engine (fig. 66).

The combustion chamber, which is eccentric with respect to the

axis, should be turned to the nozzle side. On pistons for RD270-278,

the combustion chamber is centered and there is no specific

mounting position. Mount connecting rod caps with reference

numbers corresponding to those on the rod (fig. 67). The coupling

clearance between big end bearing and pins is: 0.020 to 0.072 mm.

Tighten up connecting rod bolts to:

Loading...

Loading...