23

COMPILER TECO/ATI ENDORSEDDATE

01.08.2003

REG. CODE

1-5302-620

MODEL N°

50902

DATE OF ISSUE

08-03

REVISION 00

X

23

24

25

26

A

B

-0,50 mm

44,505

÷

44,515

44,494

÷

44,510

-0,25 mm

44,755

÷

44,765

44,744

÷

44,760

STD mm

45,005

÷

45,015

44,994

÷

45,010

47,965 ÷ 47,985

48,965 ÷ 48,985

CHECKS AND OVERHAUL

Dimensions

Undersize bearing bushes are already available at the necessary

sizes without requiring any adjustment by boring.

Main bearing bushes with increased external diameters are also

available. Table indicates the crankcase boring values.

Crankshaft

Whenever the engine is dismantled, particularly for the replacement

of cylinders and pistons due to wear caused by the aspiration of

dust, it is good practice to check the condition of the crankshaft.

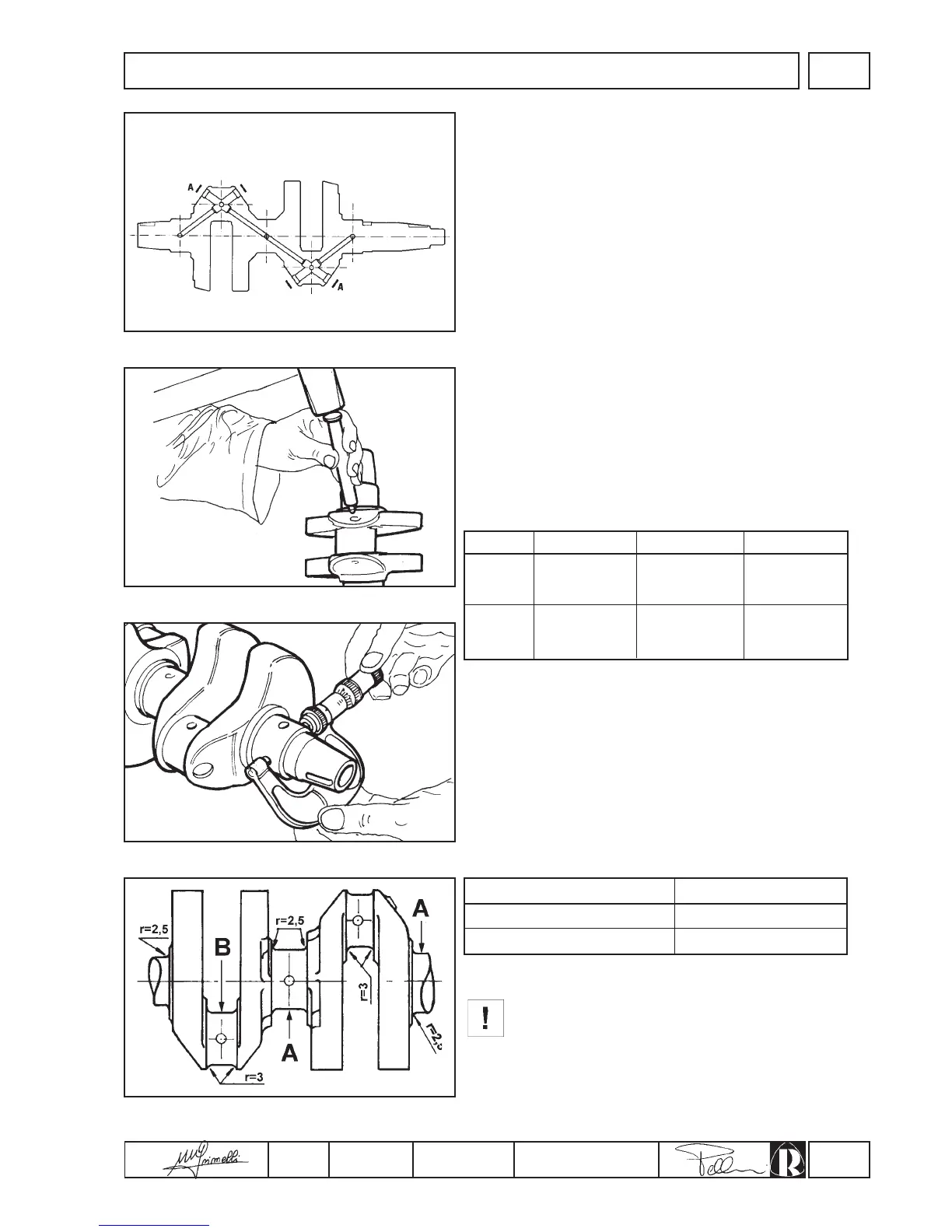

1.Remove the plugs “A” from the oil passages (fig.23).

2.Use an appropriately shaped steel punch to clean the inside of

the oil passages and the collection traps. If the deposits are

particularly resistant, immerse the whole crankshaft in petrol or

paraffin before proceeding with the operations.

3.When the oil passages and traps have been throughly cleaned,

close the openings with new plugs (fig.24).

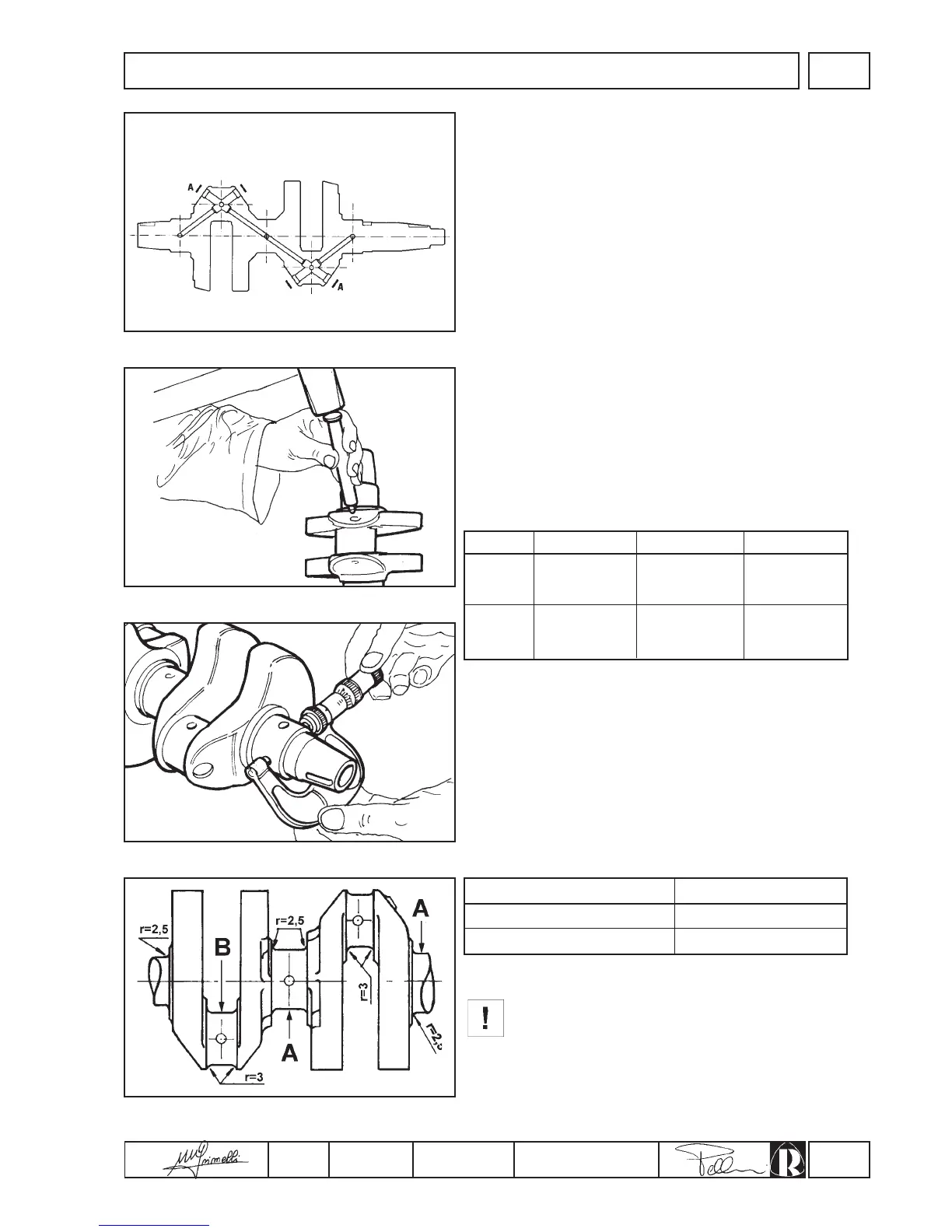

Checking crankshaft dimensions

Once the crankshaft has been thoroughly cleaned, use a

micrometer to check the wear and ovality of the main journals and

crank journals across two sections at right angles to each other

(fig.25).

If wear exceeds 0.08 mm (fig.26) grind the crankshaft to the

dimensions shown in the table:

Bearing

Standard

+ 1 mm

Ø of brush housingmm

During grinding take care not to remove the shim

adjustment material from the main journal thrust face to

avoid changing the crankshaft end float; also ensure that

the grinding wheel radii are as specified in figure 26 so as

not to create crack initiation sections on the crankshaft.

Loading...

Loading...