Revised 10/02/2012 1.7

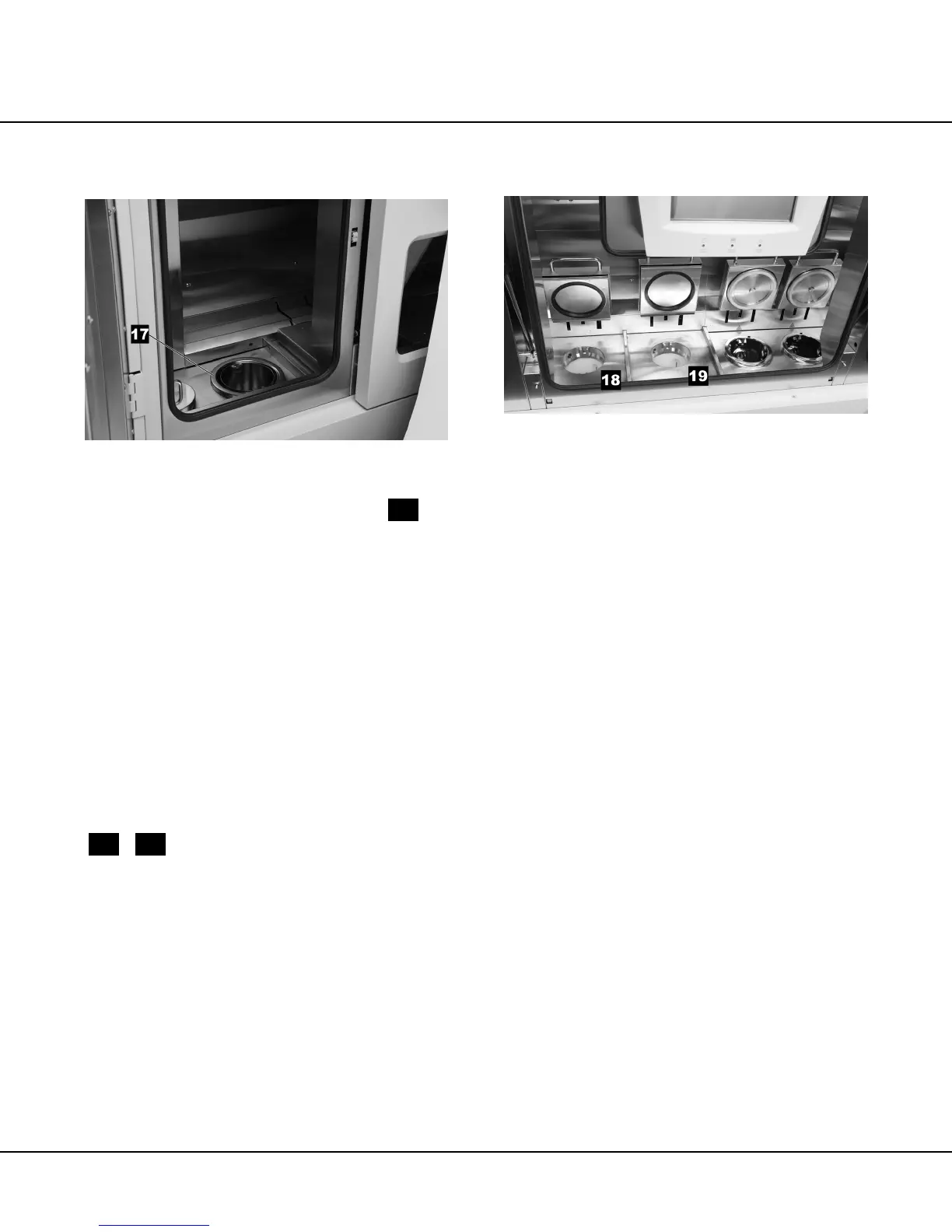

Loading Station (Figure 1-F)

Figure 1-F

The Loading Station (Figure 1-F) is an unheated, rea-

gent-filled, removable stainless steel container

..17

.. that

facilitates the loading of a single basket or two Paraform

®

magazines, containing a maximum of 40 tissue cassettes,

into the Tissue-Tek Xpress x120. The Loading Station

retort holds a maximum of approximately 1.8 liters of

reagent (Preprocessing Solution, product code 7115).

Access to the Loading Station is facilitated by an ac-

cess door in the Cabinet Front (see “Cabinet Front (Figure

1-A)” on page 1.3 for details).

A removable lid protects the retort contents (reagent)

when the instrument is not in operation.

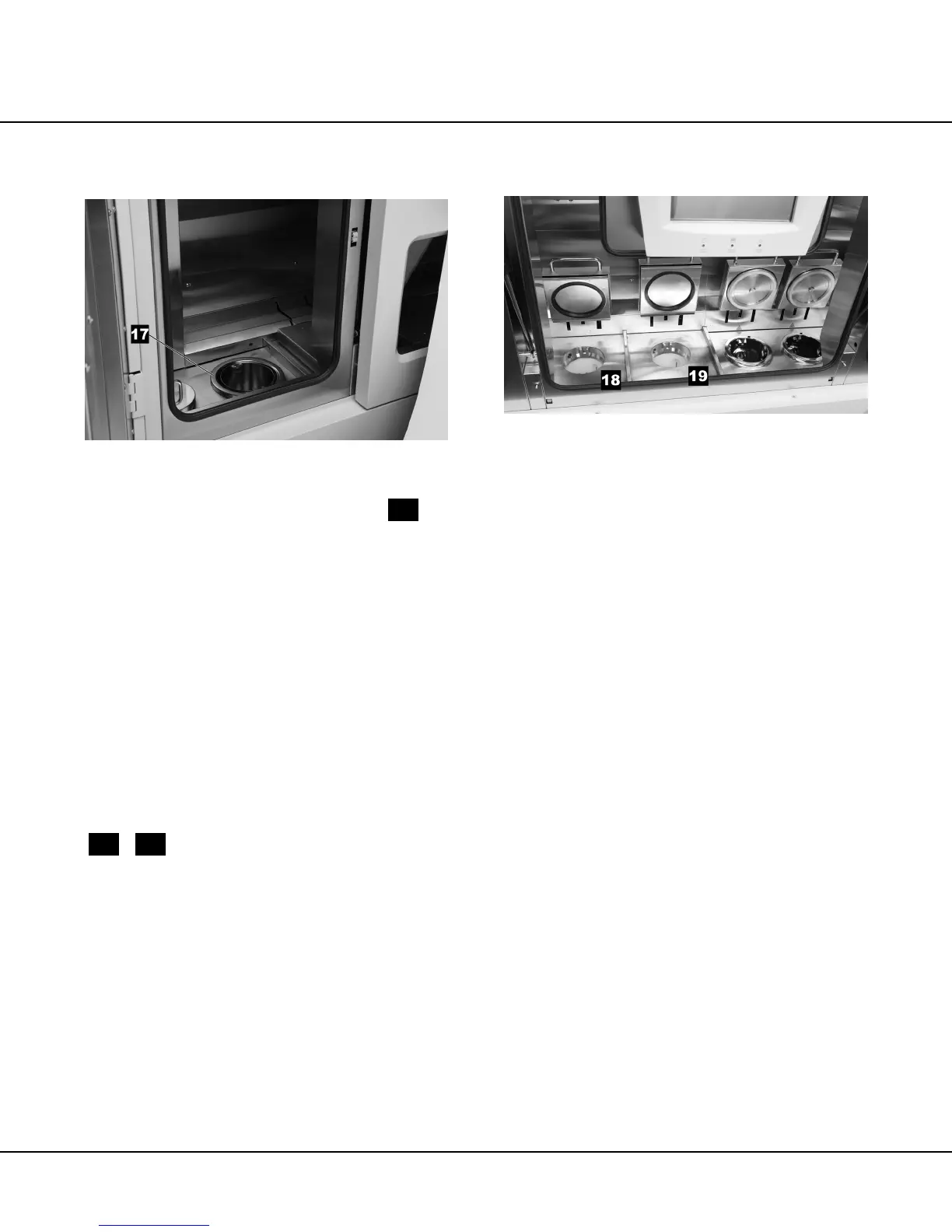

Microwave Stations (Retorts #1 and #2)

NOTE: Retort #1 and Retort #2 are identical.

At these Mircrowave Stations (Retorts #1 and #2)

(

..18

..,

..19

.., Figure 1-G) dehydration and clearing

processes are performed. The reagent in the Microwave

Station retorts is heated by radiating microwaves. Each

Microwave Station is comprised essentially of a micro-

wave retort and associated microwave unit (microwave

applicator and power supply), preheating chamber,

reagent container, and reagent cabinet.

Microwave Retorts (Figure 1-G)

Figure 1-G

Each microwave retort supports the processing of a

single basket or two Paraform magazines containing a

maximum of 40 cassettes. Each microwave retort has a

designated reagent supply level of approximately 1.44

liters, with a maximum capacity of approximately 1.74

liters. Filing and draining of the retorts is accomplished by

a reagent flow circuit operating under software control.

The flow control circuit incorporates an interlock that

prevents reagent from draining out of the retort if a

reagent container is not in place in the reagent cabinet.

A two-level reagent level detector is provided. The

lower level is used to stop supplying reagent when

replenishing; the upper level is used to prevent reagent

overflow. When the upper level sensor is actuated, an

audible alarm sounds, and the line pump is stopped.

A software controlled temperature regulation unit al-

lows control of reagent temperature at 51°C. The set

temperature for the microwave retorts is established

during installation, according to elevation of the installation

site. A bubbling pump is employed to supply volatilized

reagent to the microwave retort to aid in equalizing the

temperature of the reagent within the retort.

A hinged lid protects the retort contents during pro-

cessing. The lid is opened automatically during transfer

operations, and may be opened manually when no power

is applied to the motor to allow for cleaning and mainte-

nance of the retort. Each retort lid has a sensor that

prevents the associated microwave unit from being

energized in the event the lid is not fully closed, and

immediately turn off the magnetron in the event the lid is

opened during processing.

Loading...

Loading...