Revised 10/02/2012 1.9

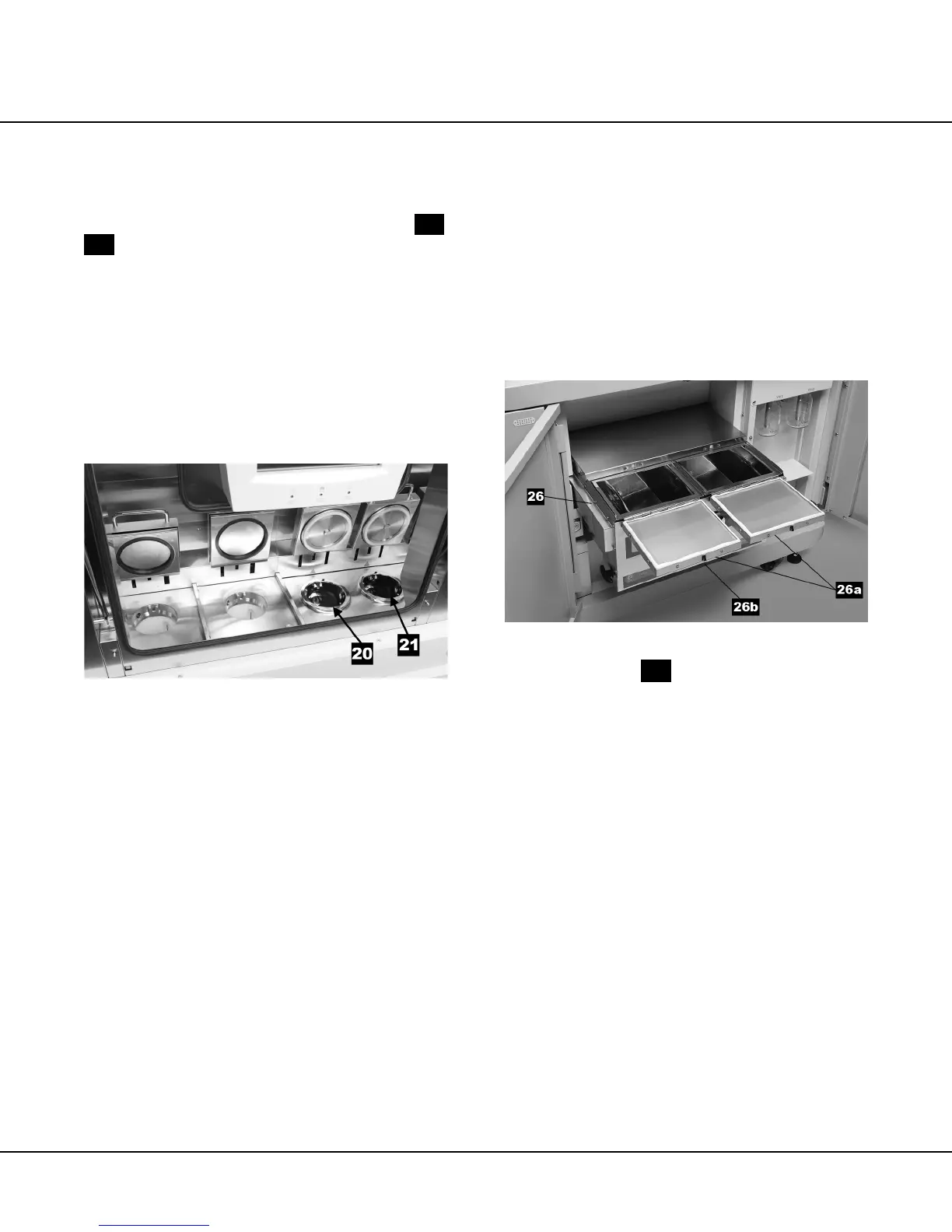

Vacuum Stations (Retorts #3 and #4)

NOTE: Retort #3 and Retort #4 are identical.

These Vacuum Stations (Retorts #3 and #4) (..20..,

..21.., Figure 1-I) are where the paraffin impregnation

processes are performed. The vacuum in the vacuum

retort increases removal of the Microwave Station

reagents from the tissue specimens, and improves

paraffin impregnation of the specimens. Each Vacuum

Station is comprised essentially of a vacuum retort with

integral retort heater, vacuum pump, paraffin oven, and

overflow bottles.

Vacuum Retorts (Figure 1-I)

Figure 1-I

Each vacuum retort supports the processing of a single

basket or two Paraform magazines containing a maximum

of 40 cassettes. Each vacuum retort has a maximum

reagent capacity of approximately 2.0 liters. Filling of the

retorts is accomplished by a vacuum pump and reagent

flow circuit operating under software control. An ultrasonic

sensor is provided for reagent level detection. The sensor

is used to stop supplying reagent (at approximately 1.7

liters), when replenishing. The retorts utilize gravity to

drain reagent to the paraffin oven.

A software-controlled temperature regulation allows

control of reagent temperature at 65°C. An over tempera-

ture control (thermal fuse) prevents overheating of the

reagent.

A hinged lid protects the retort contents during pro-

cessing. The lid is opened automatically during transfer

operations, and may be opened manually when no power

is applied to the motor to allow for cleaning and mainte-

nance of the retort.

Vacuum pumps are used to pump reagent (melted

paraffin) into the Vacuum Station retorts. The vacuum

pump for Vacuum Retorts applies vacuum for 80 seconds,

and then is off for 10 seconds (no vacuum applied). This

cycle is repeated continuously.

Reagent is drained from the Vacuum Station retorts to

the paraffin oven by gravity. Drain time is approximately

five minutes.

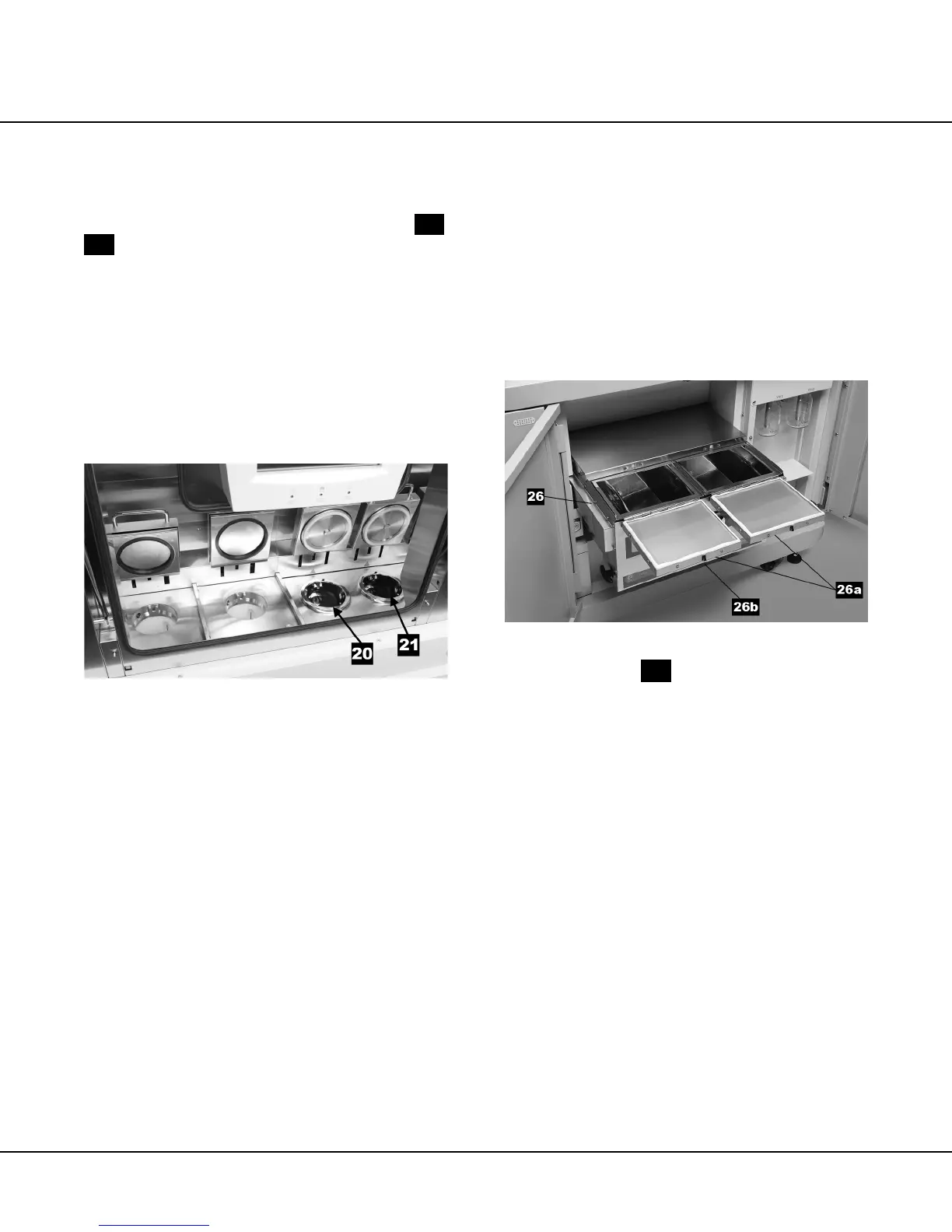

Paraffin Oven (Figure 1-J)

Figure 1-J

The paraffin oven

..26

.. is accessed through a door in

the cabinet front (see “Cabinet Front (Figure 1-A)” on page

1.3 for details). The paraffin oven is a two-compartment,

drawer-mounted container that provides for the storage

and heating (melting) of the Vacuum Station reagents.

The oven has the capability to melt paraffin at a rate of 2.4

kg (3.0 liters) within 4 hours. Temperature of the paraffin

oven is controlled at the set temperature of Vacuum

Stations Retorts #3 and #4 by a software-controlled

temperature regulation unit. An over temperature control

(thermal fuse) prevents overheating of the reagent.

The oven incorporates separate compartments for

Vacuum Station Retort #3 and Vacuum Station Retort #4

reagents. Each compartment has a capacity of approxi-

mately 3.0 liters of paraffin chips. A reagent level mark in

each compartment indicates the proper reagent level

inside the compartment (approximately 3.0 liters).

Loading...

Loading...