Revised 10/02/2012 1.11

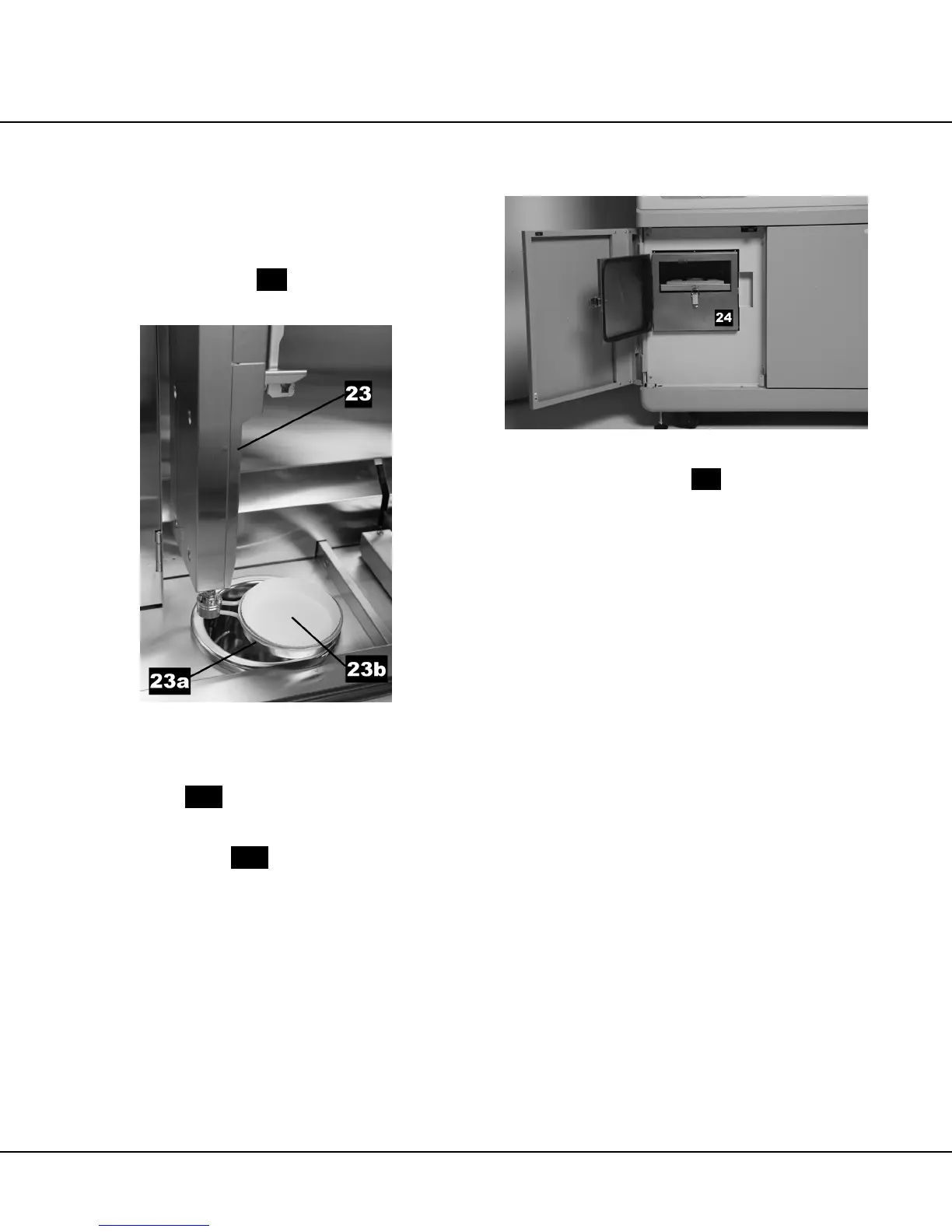

Transfer System (Figure 1-M)

The Transfer System performs the automated process

of transferring baskets from the Loading Station to the

Microwave and Vacuum Stations, and ultimately to the

Unloading Station. The Transfer System is comprised of a

motor-driven transfer arm

..23

.. that provides for move-

ment in the X (horizontal) and Z (vertical) axes.

Figure 1-M

When the instrument is not processing specimens, the

transfer arm can be moved manually.

A drip pan

..23a

.. associated with the transfer arm

prevents reagent from dripping onto the top panel in the

instrument when a basket is transferred between stations.

A disposal tray liner

..23b

.. receives reagent drips. A

rotational drive associated with the drip pan automatically

retracts the drip pan to allow the transfer arm to raise or

lower a basket. The drip pan is returned to its location

beneath the basket while traveling horizontally between

stations.

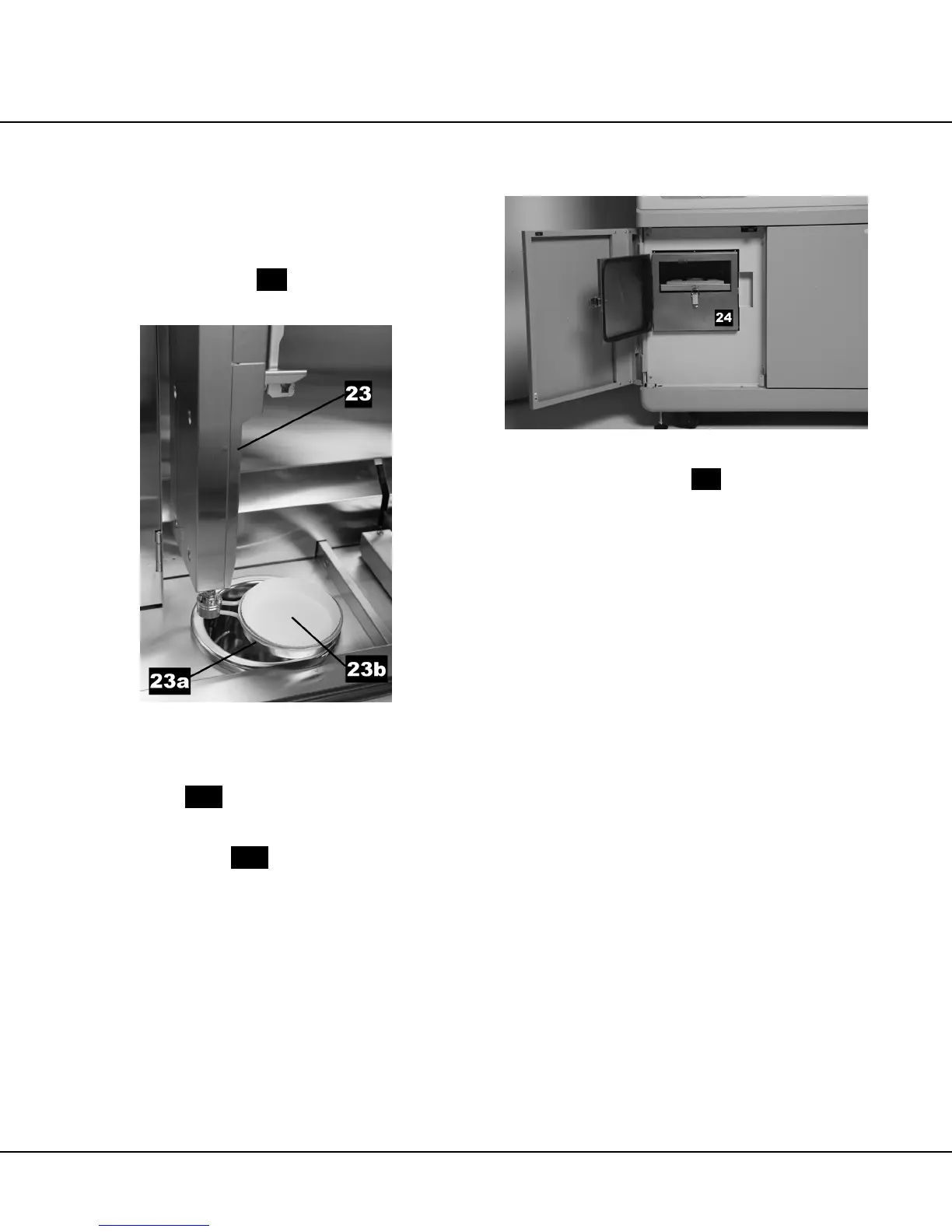

Fume Control System (Figure 1-N)

Figure 1-N

The Fume Control System ..

24

..

is comprised essential-

ly of a hood, activated carbon absorption filter, and

exhaust fan. The Fume Control System is accessed

through a door in the cabinet front (see “Cabinet Front

(Figure 1-A)” on page 1.3 for details).

The Fume Control System hood serves to prevent

hazardous fumes from leaking to the outside of the

instrument. The system collects reagent fumes from inside

the instrument and passes them through an activated

carbon absorption filter to reduce fume emissions to

acceptable levels. The filtered air is then discharged to the

atmosphere. The fume control exhaust fan is active

whenever power is applied to the instrument. In the event

the fume control exhaust fan fails while the instrument is in

operation (processing is being performed), an audible

alarm sounds.

Additionally, a duct is provided on the instrument rear

panel to facilitate connection of the Fume Control System

to a facility exhaust system.

Loading...

Loading...