EB 8359-2 EN 5-7

Installation

For tight-closing valves, the maximum signal

pressure pst

max

is roughly estimated as fol-

lows:

pst

max

= F +

d² · π · ∆p

[bar]

4 · A

d = Seat diameter [cm]

∆p = Differential pressure across the valve

[bar]

A = Actuator area [cm²]

F = Upper bench range value [bar]

If there are no specications, calculate as

follows:

Required supply pressure =

Upper bench range value + 1bar

The positioner output pressure is routed to

the top or bottom diaphragm case of the ac-

tuator as shown in Fig.5-2 to Fig.5-5.

5.5 Selecting the range spring

The attached lever and the installed range

spring of the positioner are assigned to the

values of rated valve travel and the set point

as in Table 5-1.

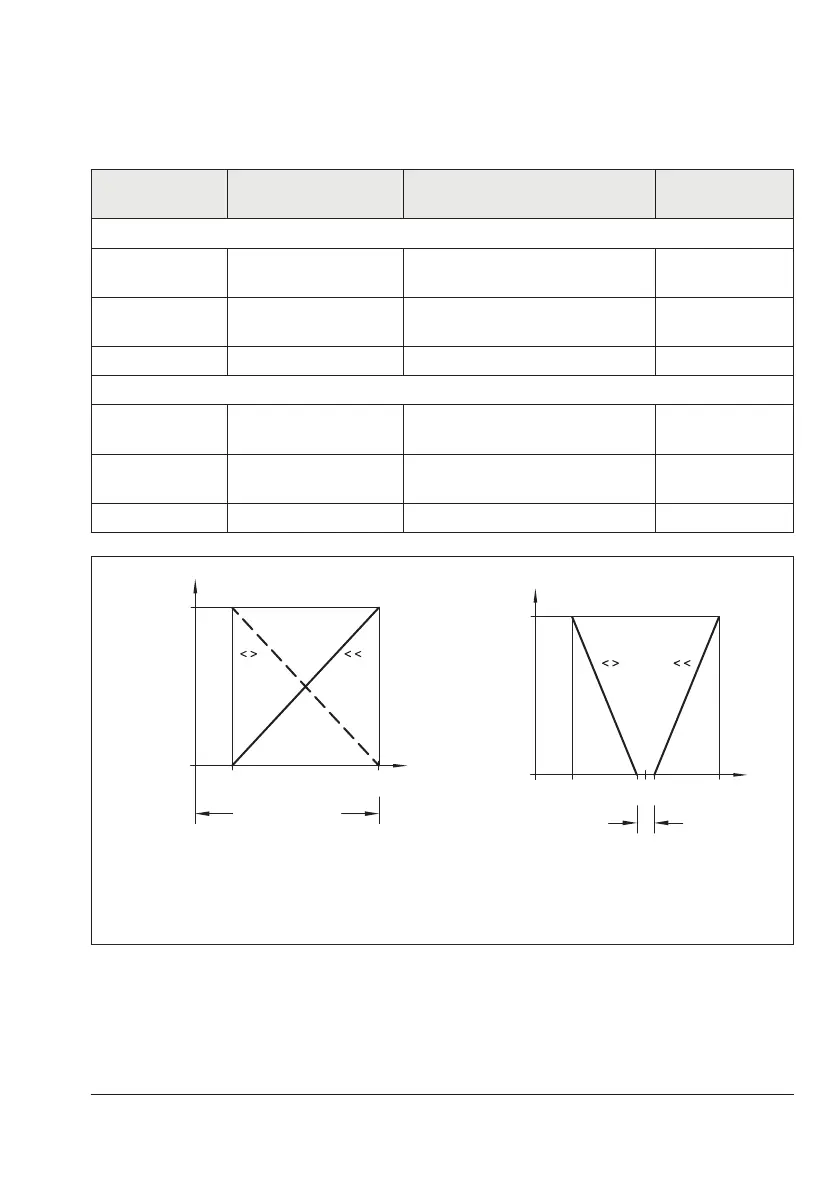

In normal operation, the set point span is

100% = 16mA. A smaller span of, for ex-

ample 50% = 8mA is only required for

split-range operation (Fig.5-8, right).

The span can be changed by exchanging the

range spring. On making adjustments to the

positioner, the travel must be adapted to the

set point and vice versa.

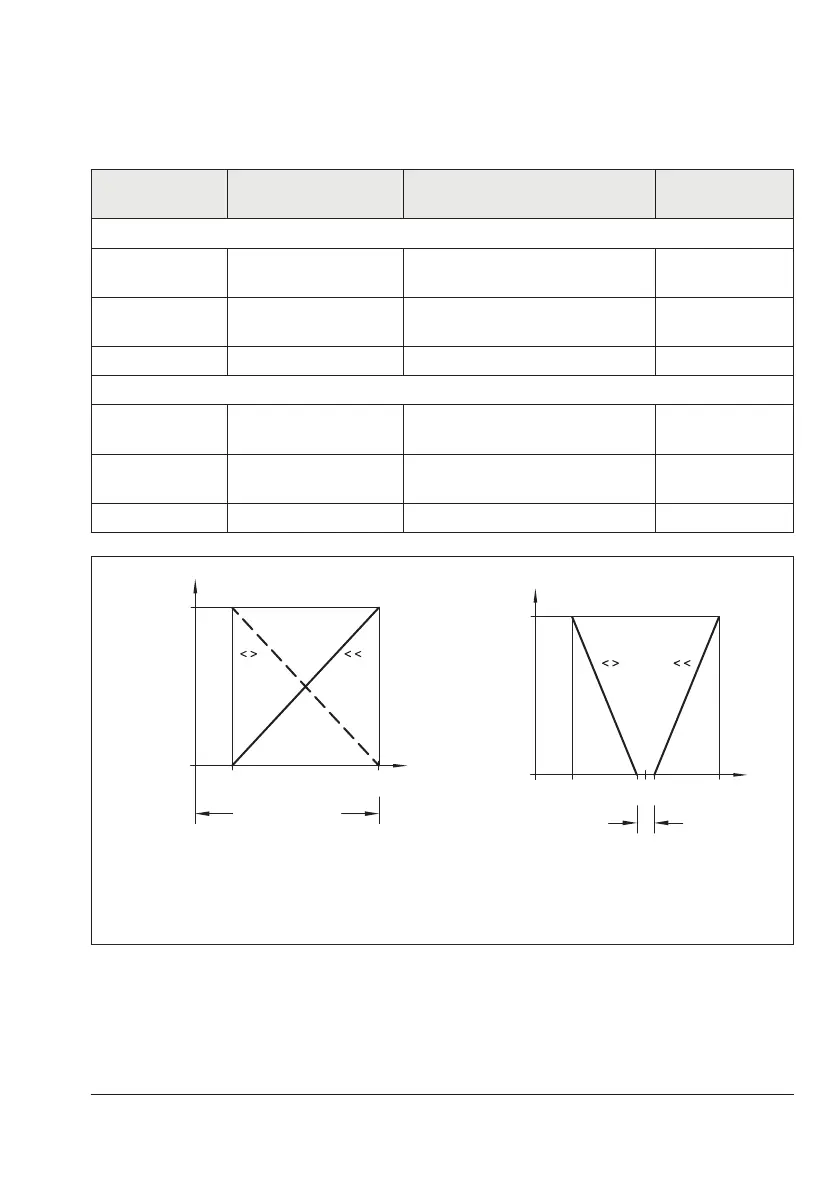

Table 5-1: Range springs

Rated travel

[mm]

Min./max. travel [mm] Set point (input signal) Range spring

Standard travels for SAMSON valves with lever l (40 to 127mm in length)

15 7.5 to 15

100%

50%

1

2

30 14 to 32

100%

50%

2

3

60 30 to 70 100% 3

Further travel ranges with lever l and lever extension (40 to 200mm in length)

20 7.5 to 26

100%

50%

1

2

40 14 to 50

100%

50%

2

3

> 60 30 to 90 100% 3

0%

4 20mA

Set point (input

signal)

Open

Travel

Closed

0%

412 20mA

Dead band

Valve 2 Valve 1

Open

Travel

Closed

Normal operation Split-range operation, two valves operating in

opposing directions

Fig.5-8: Normal or split-range operation

Loading...

Loading...