2003-10:1 © Scania Industrial & Marine Engines 31

- Wash all parts in diesel oil.

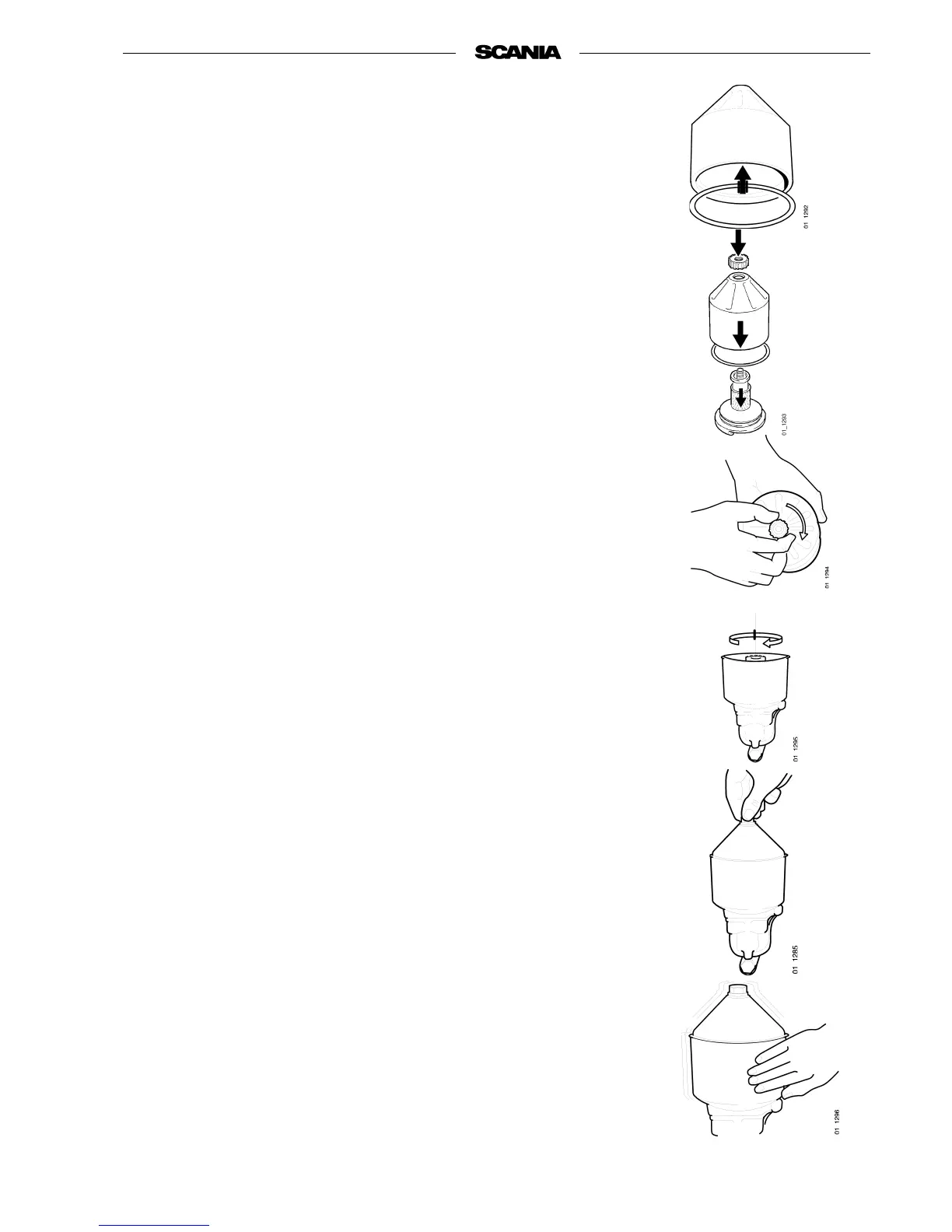

- Fit the O-ring in the rotor bowl. Make sure it is not damaged.

Change if necessary.

- Assemble the rotor.

- Tighten the rotor nut firmly by hand

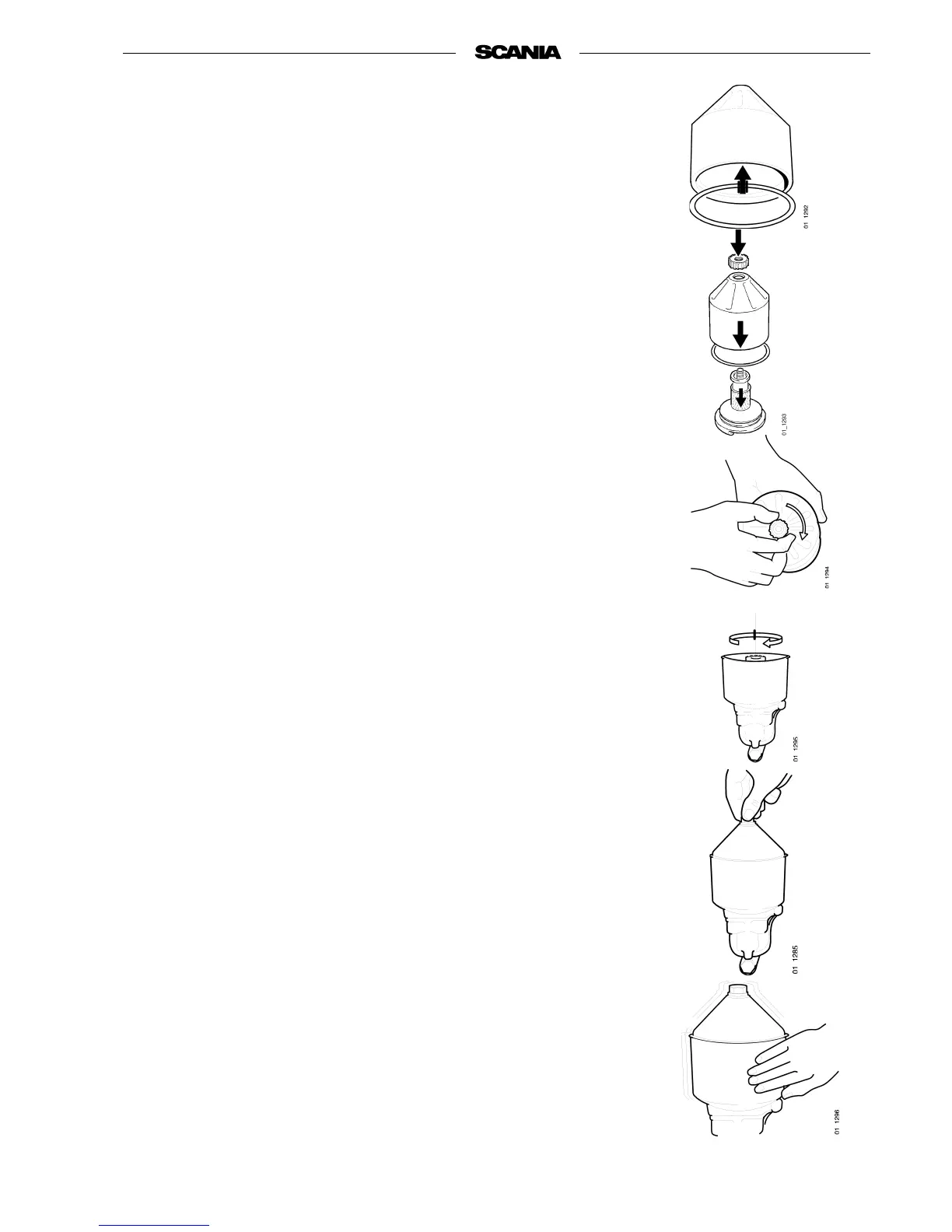

- Refit the rotor.

- Make sure that it spins easily.

- Check that the O-ring in the bowl is undamaged.

A hardened or damaged O-ring must be changed.

- Screw the bowl down hard by hand

If the nut is tightened with a tool, the rotor shaft, nut or bowl may be

damaged.

Functional inspection

The rotor rotates very fast and should continue to rotate when the engine has

stopped.

- Stop the engine when it is warm.

- Listen for a whirring sound from the rotor or feel whether the cleaner

housing is vibrating.

The rotor normally continues spinning for 30 - 60 seconds after the engine

has stopped.

If it does not: dismantle it and inspect the component parts.

Loading...

Loading...