2003-10:1 © Scania Industrial & Marine Engines 35

c)

Checking protection against corrosion

There must always be sufficient corrosive inhibitor in the coolant to protect

the cooling system against corrosion.

If there is no danger of freezing, only Scania Corrosion Inhibitor should be

used in the coolant.

The inhibitor in Scania Corrosion Inhibitor is free of nitrite.

The correct proportion of anti-corrosive is 7-12% by volume.

- Topping up with 1.0% Scania Corrosion Inhibitor by volume should be

done after every 2400 hours of operation.

- Never top up with only water or only anti-corrosive!

Fluid losses must always be replaced with blended coolant:

water + 10% Scania Corrosion Inhibitor by volume.

Note: The coolant should be changed when the cooling system is

cleaned:

every 4800 hours or at least every 5th year.

Changing the coolant

1. Remove the filler cap from the expansion tank.

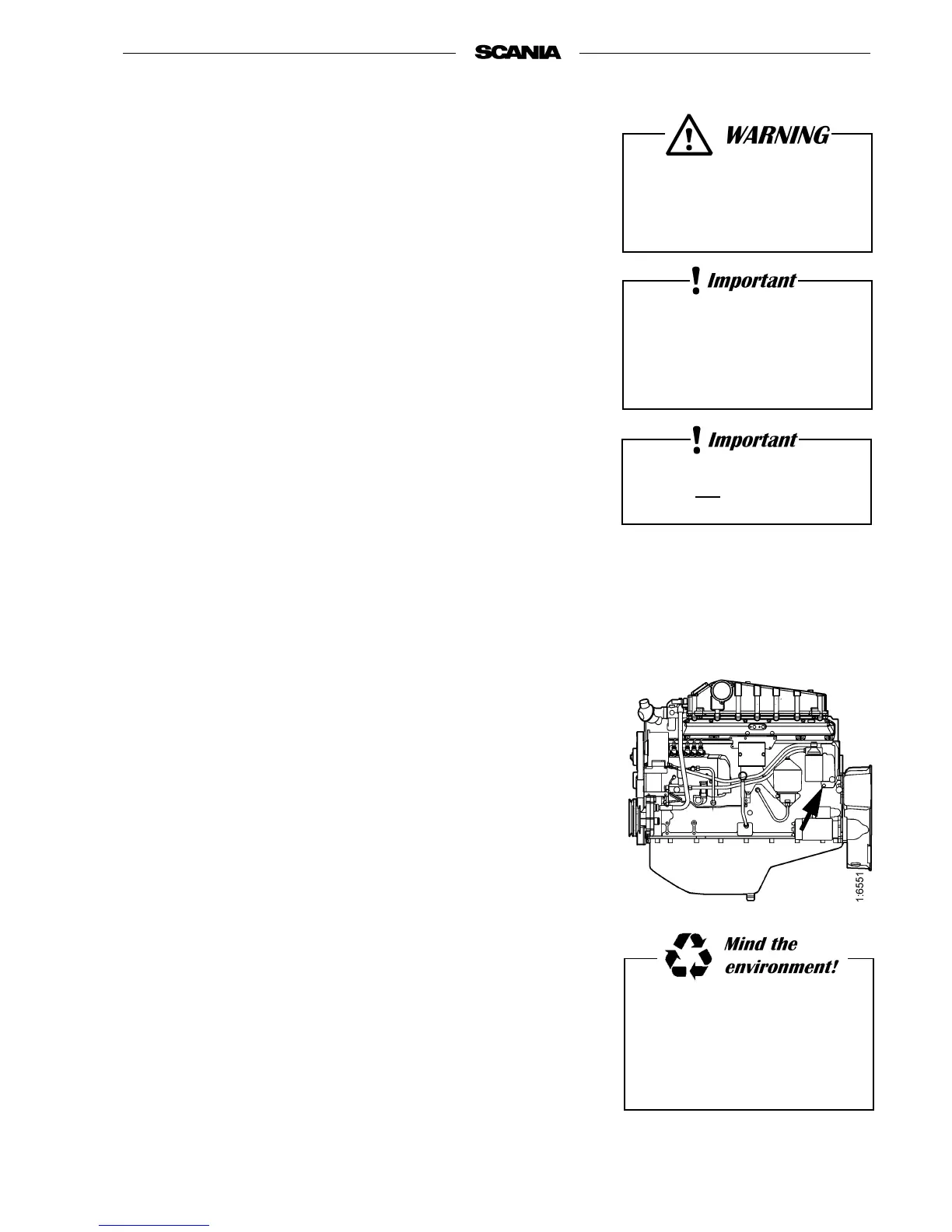

2. The coolant is drained at two points:

- the "lowest point" of the engine block, see illustration.

- the "lowest point" of the cooling system.

3. Close the drain taps.

4. Fill up with coolant through the expansion tank's filler hole.

Mix coolant as described on page 33.

Use a container to avoid spillage

when changing the coolant.

Dispose of used coolant through

an authorised waste disposal

contractor.

If a coolant filter has been fitted

it must not

contain inhibitor.

Mixing with glycol or the use of

too much corrosion inhibitor

can lead to build up of sludge

and reduced cooling capacity.

It is highly dangerous to

consume corrosion inhibitor.

Avoid contact with the skin.

Loading...

Loading...