2003-10:1 © Scania Industrial & Marine Engines 41

14. Every 2400 hours:

CHECKING THE INJECTORS

Injectors should be inspected by trained personnel with access to the

necessary equipment. Inspection should be carried out at least once a year or

every 2400 hours.

Removal

1. Clean round the injectors and connections, including clamps and

brackets.

2. Detach the delivery pipe bundle and leak-off fuel lines.

3. Unscrew the injector.

4. Fit protective plugs on the injector and delivery pipe.

5. Lift up the sealing washer from the bottom of the injector seat if it does

not come out together with the injector.

6. Fit a core plug in the injector seat in the cylinder head.

7. Clean the injectors and check/adjust a nozzle tester.

Correct opening pressure, see Technical data, page 54.

Fitting

1. Check that there is no old sealing washer in place and fit a new sealing

washer in the bottom of the injector seat.

2. Fit a new O-ring in the threaded socket nut and a new sealing ring under

the socket nut.

3. Fit the injector.

4. Tighten the socket nut to 70 Nm (7.0 kpm).

5. Fit the delivery pipe and tighten the cap nuts to 20 Nm (2.0 kpm). Fit

clamps and brackets.

Take care to fit the delivery pipe without tension and make sure that

the cone on it is correctly positioned in the connection.

6. Fit the leak-off fuel line. Tighten the bolts to 11 Nm (1.1 kpm).

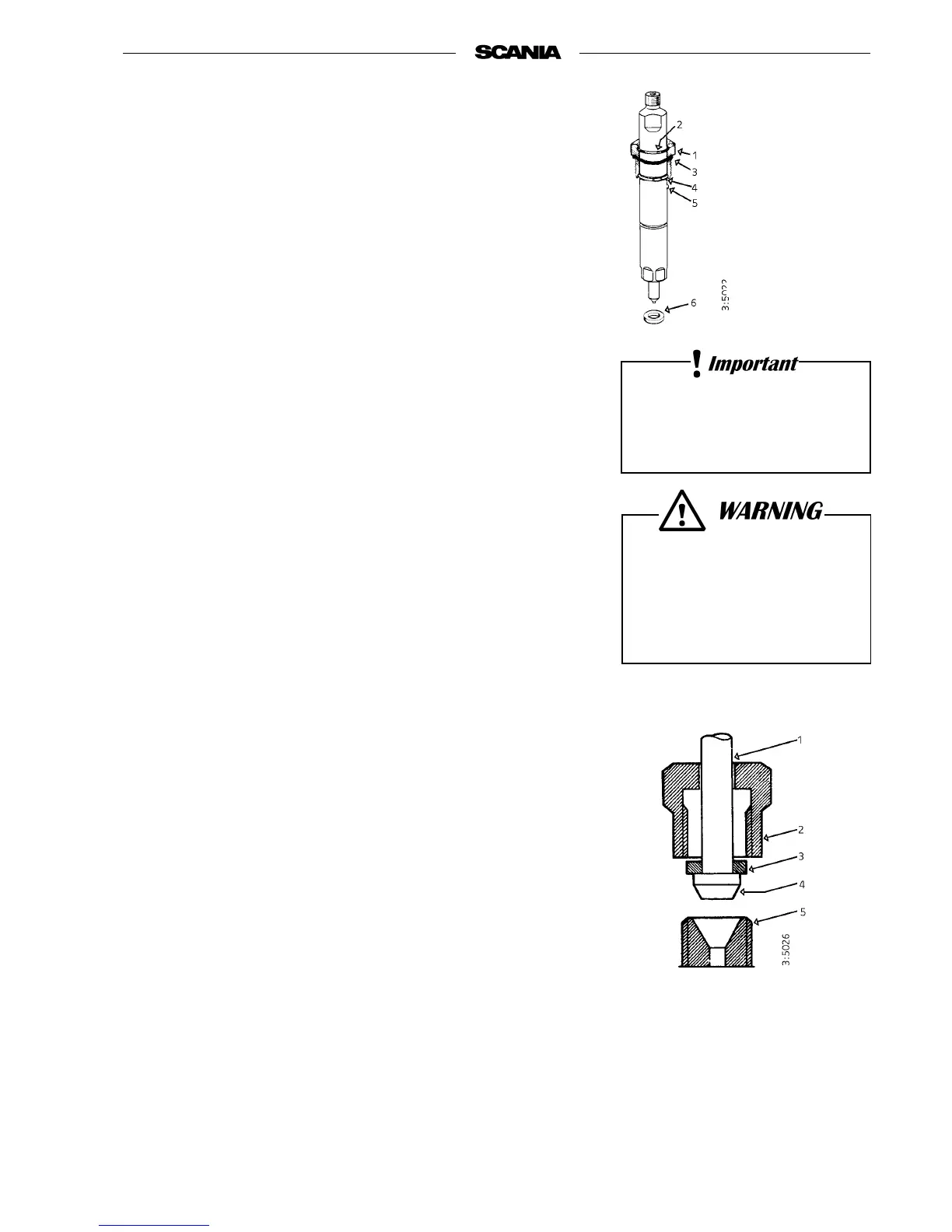

1. Threaded

socket nut

2. O-ring

3. O-ring

4. Stop ring

5. Guide pin

6. Sealing washer

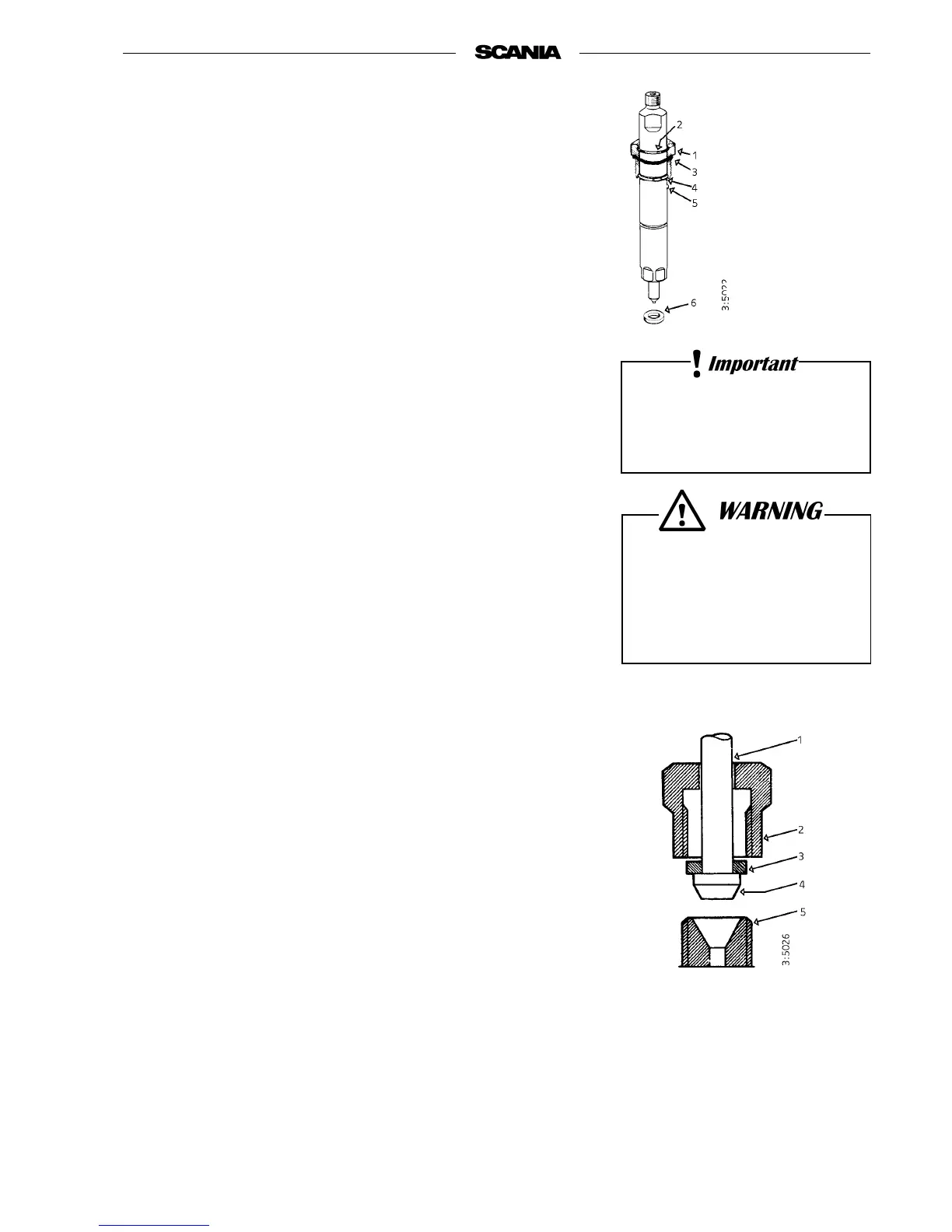

1. Delivery pipe

2. Cap nut

3. Washer

4. Cone

5. Connection on injector or

injection pump

The delivery pipes must not be

bent.

All clamps must be refitted.

Also wear protective goggles

when testing injectors.

A jet from the injector can

penetrate tissue and cause

serious injury.

Loading...

Loading...