www.scheppach.com service@scheppach.com +(49)-08223-4002-99 +(49)-08223-4002-58

26 І GB

Damaged electrical connection cable

The insulation on electrical connection cables is of-

ten damaged.

This may have the following causes:

• Passage points, where connection cables are

passed through windows or doors.

• Kinks where the connection cable has been im-

properly fastened or routed.

• Places where the connection cables have been cut

due to being driven over.

• Insulation damage due to being ripped out of the

wall outlet.

• Cracks due to the insulation ageing.

Such damaged electrical connection cables must not

be used and are life-threatening due to the insula-

tion damage.

Check the electrical connection cables for damage

regularly. Make sure that the connection cable does

not hang on the power network during the inspection.

Electrical connection cables must comply with the

applicable VDE and DIN provisions. Only use con-

nection cables with the marking „H05VV-F“.

The printing of the type designation on the connec-

tion cable is mandatory.

AC motor

• The mains voltage must be 230 V~

• Extension cables up to 25 m long must have a

cross-section of 1.5 mm

2

.

Connections and repairs of electrical equipment may

only be carried out by an electrician.

Please provide the following information in the event

of any enquiries:

• Type of current for the motor

• Machine data - type plate

• Machine data - type plate

Cleaning and Servicing

Pull the mains plug before any adjustments,

maintenance or repair.

m Have any work on the device that is not de-

scribed in this instruction guide performed by a

professional. Only use original parts. Allow the

device to cool off before any maintenance or

cleaning is undertaken. There is a risk of burn-

ing!

Always check the device before using it for obvi-

ous defects such as loose, worn or damaged parts,

correct the positioning of screws or other parts. Ex-

change the damaged parts.

Cleaning

Do not use any cleaning agents or solvents. Chemi-

cal substances can etch the plastic parts of the de-

vice. Never clean the device under running water.

• Thoroughly clean the device after every use.

• Clean the ventilation openings and the surface of

the device with a soft brush or cloth.

To switch ON: Move the ON/OFF switch (13) to the

“I” position to switch on the laser. Two laser lines are

projected on the workpiece and intersect at the cent-

er of the drill tip contact point.

To switch OFF: Move the ON/OFF switch (13) to the

“0” position.

Setting the laser (Fig.15+16)

The laser can be adjusted via the adjusting screws (T)

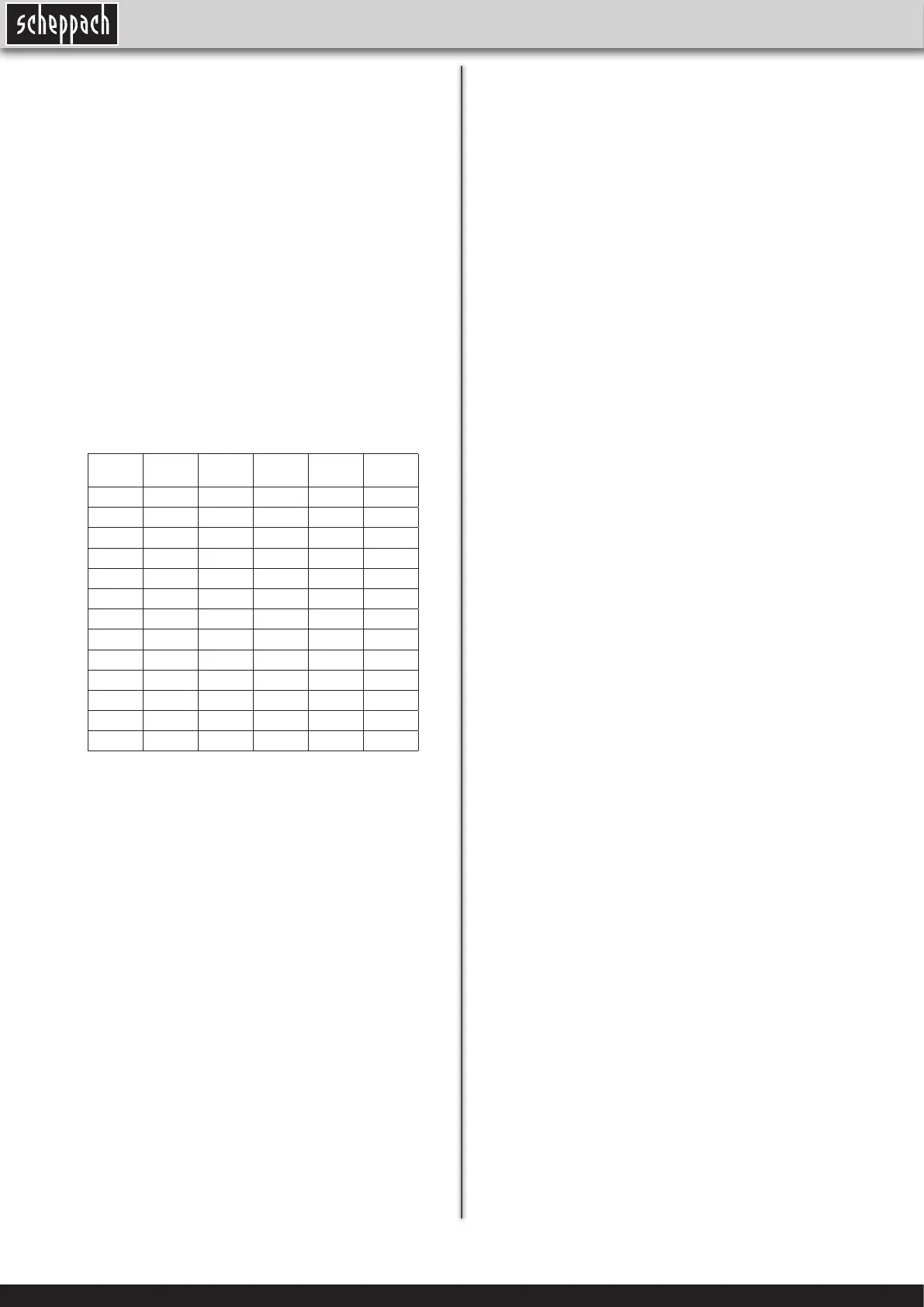

Working speeds

Ensure that you drill at the proper speed. Drill speed

is dependent on the diameter of the drill bit and the

material in question.

The table below acts as a guide for selecting the

proper speed for various materials.

The drill speeds speci ed are merely suggested

values.

Drill

bit Ø

Cast

iron

Steel Iron Alumin-

ium

Bronze

3 2550 1600 2230 9500 8000

4 1900 1200 1680 7200 6000

5 1530 955 1340 5700 4800

6 1270 800 1100 4800 4000

7 1090 680 960 4100 3400

8 960 600 840 3600 3000

9 850 530 740 3200 2650

10 765 480 670 2860 2400

11 700 435 610 2600 2170

12 640 400 560 2400 2000

13 590 370 515 2200 1840

14 545 340 480 2000 1700

16 480 300 420 1800 1500

Countersinking and center-drilling

With this table drill, you can also countersink and

center-drill. Please observe that countersinking

should be performed at the lowest speed, while a

high speed is required for center-drilling.

Drilling wood

Please note that sawdust must be properly evacuated

when working with wood, as it can pose a health haz-

ard. Ensure that you wear a suitable dust mask when

performing work that generates dust.

Electrical connection

The electrical motor installed is connected and

ready for operation. The connection complies

with the applicable VDE and DIN provisions.

The customer‘s mains connection as well as

the extension cable used must also comply with

these regulations.

Important information

In the event of an overloading the motor will switch

itself off. After a cool-down period (time varies) the

motor can be switched back on again.

Loading...

Loading...