7/12 Ref. GPAO : 33522111601 Ref. Const. 5490 326 4000

5. Protective devices (if fitted, see specifications table)

5.1. Oil failure cut-out

This mechanism is designed to prevent any damage to the engine resulting from lack of oil in the engine sump. It

stops the engine automatically (in this case, the red oil level warning light is turned on and stops the starting

process). If the engine cuts out and will not restart, check the engine oil level before looking for any other cause

of the problem.

5.2. Circuit breaker

The electrical circuit of the set is protected by several magnetothermal, differential or thermal cut-out switches.

Any overload and/or short circuits cause the supply of electrical energy to be cut.

5.3. Overcharge

When there is electrical overcharge, the overcharge indicator turns on and electrical current production cuts out

in less than 20 seconds.

6. Maintenance schedule

6.1. Usage reminder

The maintenance interval frequency and the operations to be carried out are outlined in the maintenance

programme.

However, it should be added that it is the environment in which the generating set is operating which determines

this programme. Accordingly, if the set is used in extreme conditions, shorter intervals between maintenance

procedures should be adopted.

These maintenance schedules apply only to generating sets running on fuel and oil, that conform to the

specifications given in this booklet.

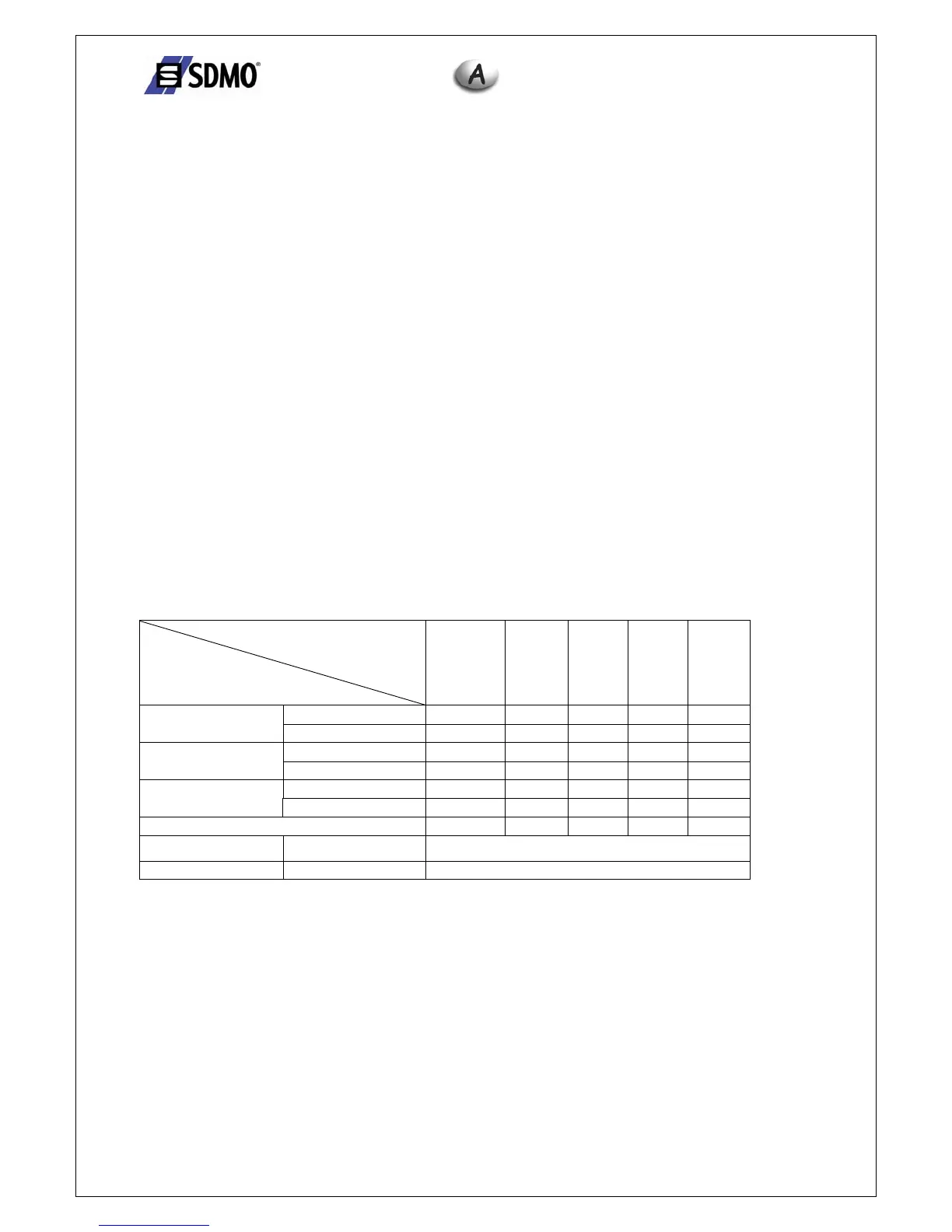

6.2. Maintenance table

carry out the maintenance

procedures at whichever

part deadline

is reached first

Each time

it is used

Within

the 1st

month or

20 hours

Every 3

months

or 50

hours

Every 6

months

or 100

hours

Every 3

years or

300

hours

Check the level

•

Engine oil

Change

•

•

Check

•

Air filter

Clean

•

Spark Check – clean

•

plug Replace

•

Cleaning the generating set

•

Valves * Check – adjust Once per year

Fuel filter * Clean Once per year

NB: * these procedures should be carried out by our registered agents

Loading...

Loading...