The usage of standard 1 A testing devices for the secondary test method is possible

nonetheless, because the WIC1 CTs have an additional winding that is dedicated for testing

purposes. These test windings are connected to the WIC1-terminals C and D for each phase,

and there are additional device-internal connections to dedicated test sockets at the front

side of the housing.

Via these test sockets, you can inject a test current into the test windings, which results in

a simulated primary current. Although this is not a real primary current owing out of the

site to be protected, it induces a current on the secondary side of the CT. Every WIC1 CT is

designed such that the ratio between test current and secondary current is the same.

NOTICE!

• Injecting currents via the test windings has a lower accuracy, compared to•

injecting primary currents. However, the accuracy should be sucient for typical

commissioning tests, such as testing the wiring or verifying that the protection

device operates as required.

• Moreover, there must be no more primary current owing during this test, because•

the injected test current adds to the primary current and this spoils the test results.

• Finally it has to be noted that the test windings transfer only a limited current range•

in a reliably linear manner. See the related Technical Data.

If you have spent care on all this but the measurements are still wrong, then check the

wiring of the contacts and the phase sequence. See also the Troubleshooting entry about

wrong measuring and tripping values.

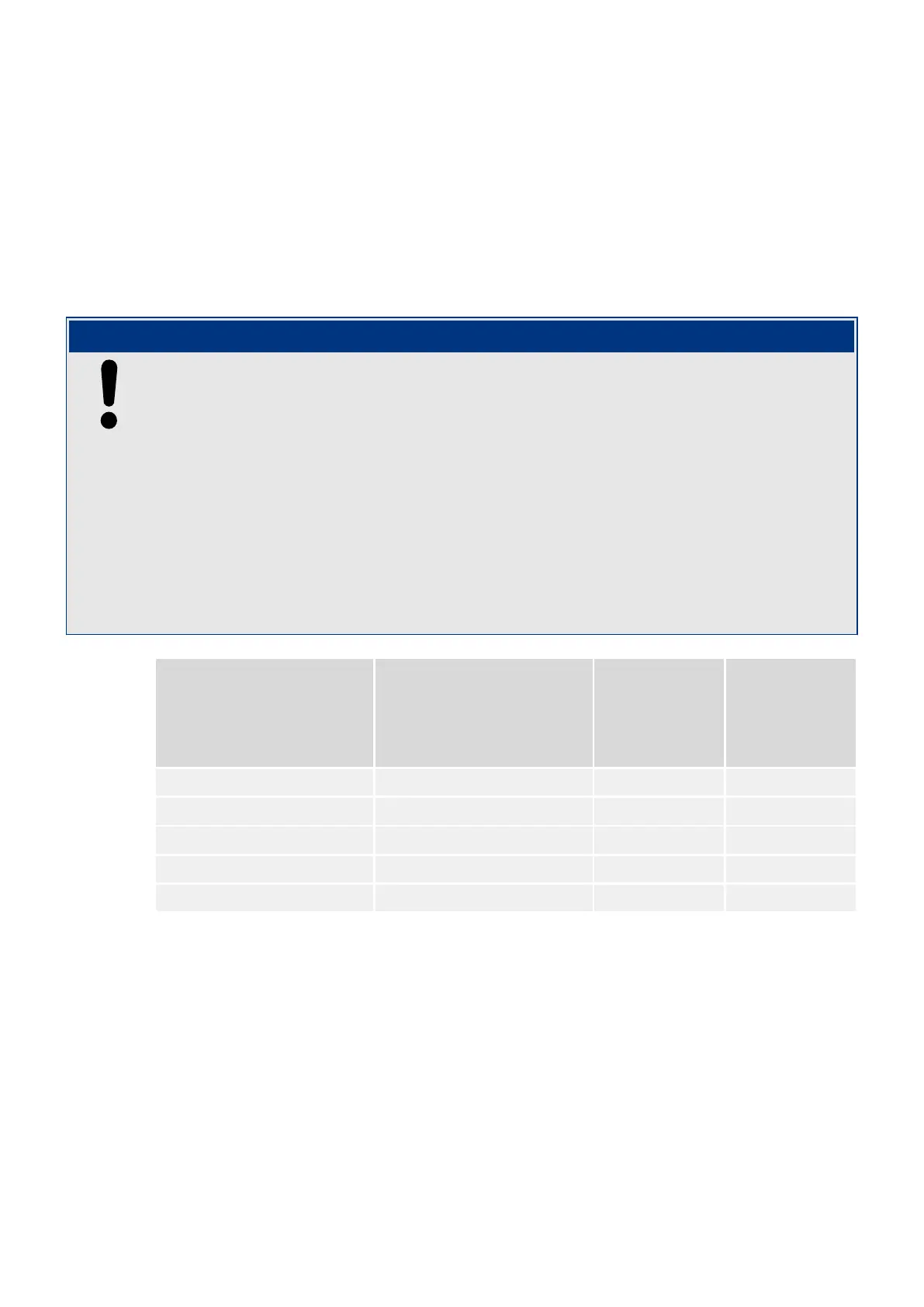

CT Type

(See also ╚═▷ “2.6.1.3

Order Form of the

WIC1-Compatible Current

Transformers”.)

Prim. Current Range Injected C–D

Test Current

Induced

Current

W2, WE2 16 … 56 A 1 A 50 A

W3 32 … 112 A 1 A 100 A

W4 64 … 224 A 1 A 200 A

W5 128 … 448 A 1 A 400 A

W6 256 … 896 A 1 A 800 A

Note: A more detailed table of test current and primary current values can be found in ╚═▷

“7.1.5.1 Test Currents”.

191WIC1WIC1-1.0-EN-MAN

7 Commissioning

7.1.4.1 Test Windings, Test Sockets

Loading...

Loading...