This parameter functions if PI is chosen as frequency source, which

means that the selection of P0-01 is option 4. The preset channel of objective

variables for PI is determined by this parameter. The setting objective

variables of PI are relative value; the percentage of the setting(100%)

corresponds to the percentage of feedback signal(100%) in the controlled

system. And operation is proceeded by the system according to the relative

value(0~100%).

When P7-00 equals zero, PI set value will be set by this parameter.

0 : Analog channel AI1

1 : Analog channel AI2

PI feedback channel is determined by this parameter.

PI output

characteristics

options

0 : Positive

1 : Negative

Positive PI output characteristics: output frequency must be lowered

to make it balance when the value of feedback signal is greater than PI set

value, for example PI control on winding tension.

Negative PI output characteristics: output frequency must be

increased to make it balance when the value of feedback signal is greater

than PI set value, for example PI control on unwinding tension.

Integral time (I)

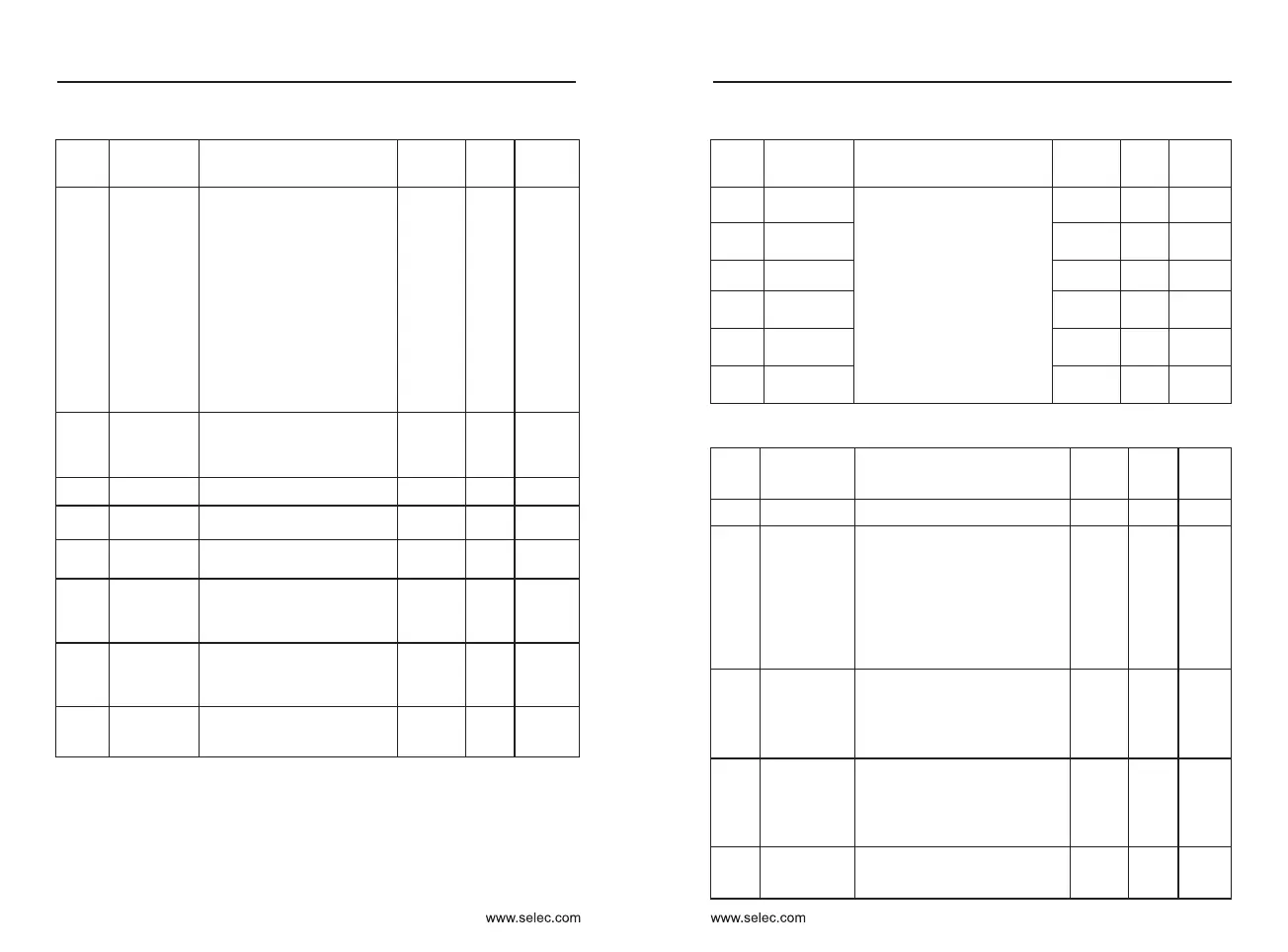

P7: PI control parameters

PI control is a common method to control the process. Output

frequency can be adjusted by proportion & integral operations on the

difference between the feedback signals of controlled variable and signals of

objective variables.

0 : Digital keyboard

1 : Panel potentiometer

2 : Analog channel AI1

3 : Analog channel AI2

Default: 0

P7-00

PI preset source

options

0.00~10.00V

Default:

0.00V

P7-01

PI set value

Default: 0

P7-02

PI feedback

source options

Default: 0

P7-03

Default:

1.0

P7-04

Proportional

gain (P)

0.0~10.0

P7-05

0.0~100.0s

Default:

0.1s

Proportional gain (P) determines the intensity of adjustment of PI

regulator; the larger P value is, the higher the intensity of adjustment will be.

PI is the most common control method for process control; the

function of each part is different from each other's. Please refer to the

following brief introduction of operating principles and regulation methods:

Integral time (I): when there is difference between feedback value

and set value, regulating variable of output should be accumulated

continuously; if the deviation can't be eliminated, the regulating variable

should be increased continuously until there is no deviation. Deviation can be

eliminated effectively by integral controller. However, overshoot may be

caused repeatedly if the adjustment of integral controller is too much, which

makes system unstable and even causes vibration. If vibration is caused by

excessive integral action, following characteristics can be observed-

oscillation of feedback signal on given quantity, expanding amplitude of

oscillation, even vibration. The parameter of integral time should be adjusted

generally from maximum value to minimum value so that the integral time

can be changed gradually. Observation should be made on the effect on the

system. Adjustment can't be stopped until the sable speed of system meets

the requirements.

Proportional gain (P): There will be proportional adjustment between

output and deviation if there is difference between feedback value and set

value; if deviation is constant, regulating variable is also constant.

Proportional control responses to the change of feedback quickly; however,

error control can't be proceeded only by proportional control. The greater

proportional gain is, the smaller adjusting speed of system will be. But the

proportional gain is excessive, it may cause vibration. The adjustment

method is to extend the integral time and make system running only by

proportional control; meanwhile, set value should be changed in order to

observe its stable deviation(static error) between feedback signal and given

quantity; if static error is in compatible with the change of given quantity,

proportional gain can be increased continuously, for example increasing

given quantity, or feedback quantity is always less than given quantity after

system is stable; otherwise, please reduce it. The instruction above should

be implemented repeatedly until deviation is optimized/minimized(tips: zero

offset is almost impossible).

Integral time (I) determines the speed of integral regulation on the

difference between PI feedback quantity and given quantity. The less integral

time is, the higher the intensity of adjustment will be.

55

54

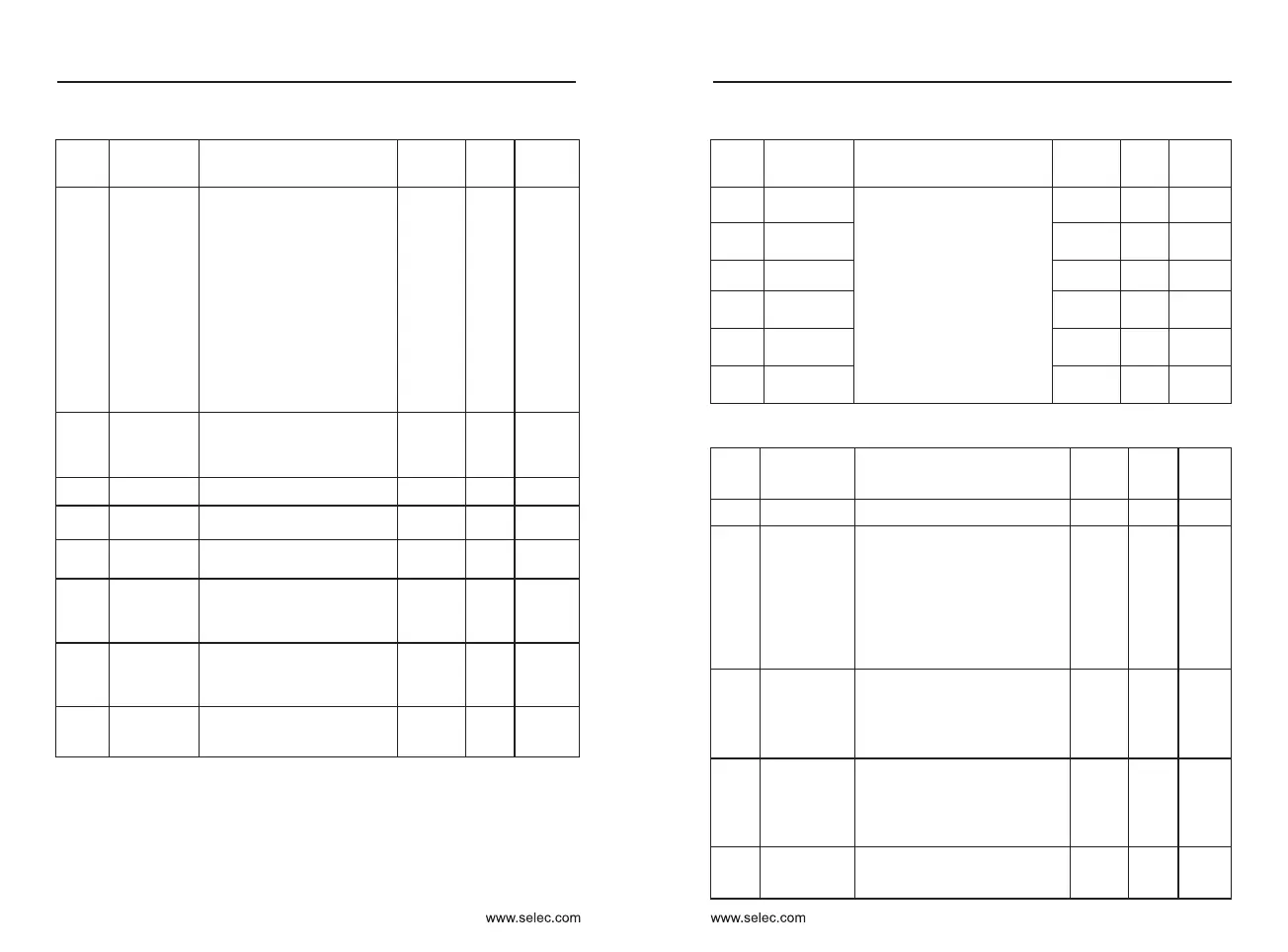

Pd: Communication parameter

Parameter

Name

Setting Range

Default

Prope-

rty

Modbus

Address

Fun-

ction

Code

Pd-00

Baud rate

5005

Pd-01

Data Format

0

Pd-02

Local address

1〜247, 0 Broadcast address

1

Pd-03

Response

delay

0ms〜20ms

2

Pd-04

Communi-

cation timeout

0.0

Pd-05

Data transfer

format

selection

30

Pd-06

Communi-

cation read

current

resolution

0

Pd-08

CANlink

communi-

cation timeout

0

Ones place : MODBUS

0 : 300BPS 1 : 600BPS

2 : 1200BPS 3 : 2400BPS

4 : 4800BPS 5 : 9600BPS

6 : 19200BPS 7 : 38400BPS

8 : 57600BPS 9 : 115200BPS

Tens place : Profibus-DP

0 : 115200BPs 1 : 208300BPs

2 : 256000BPs 3 : 512000Bps

(Hundreds place : Reserved)

Thousands place : CANlink

Baud rate

0 : 20 1 : 50 2 : 100

3 : 125 4 : 250 5 : 500

6 : 1M

0 : no checking(8-N-2)

1 : even checking(8-E-1)

2 : odd checking(8-O-1)

3 : no checking(8-N-1)

0.0 (Invalid)

0.1s~60.0s

Ones place :

0 : Non-standard MODBUS

protocol

1 : Standard MODBUS protocol

0 : 0.01A

1 : 0.1A

0.0s : Invalid

0.1~60.0s

PE: Customized function code

Parameter

Name

Setting Range

Default

Prope-

rty

Modbus

Address

Fun-

ction

Code

PE-00

User function

code 0

U3-17

PE-01

User function

code 1

U3-16

PE-02

User function

code 2

P0.00

Res-

erved

Reserved Reserved

PE-28

User function

code 28

P0.00

PE-29

User function

code 29

P0.00

P0-00~PP-XX

A0-00~AX-XX

U0-XX~U0-XX

U3-00~U3-XX

PP: Function code management

Fun-

ction

Code

Parameter

Name

Setting range

Default

Prope-

rty

Modbus

Address

PP-00

User password

0〜65535 0

PP-01

Parameter

initialization

0

●

PP-02

Function

parameter

group display

selection

11

●

PP-03

Personality

parameter

group display

selection

00

PP-04

Parameter

modification

property

0 : Can be modified

1 : Cannot be modified

0

0 : no operation

1 : Restore factory value,

excluding motor parameters

2 : Clear record information

3 : Restore factory values,

including motor parameters

4 : Backup user current

parameters

501: Restore user backup

parameters

Ones place : U group display

0 : not displayed

1 : display

Tens place : A group display

0 : not displayed

1 : display

Ones place : User customization

0 : Do not display

1 : Display

Tens place : User change

0 : Do not display

1 : Display

User Manual

Chapter 5

User Manual

Chapter 5

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

64769

64770

64771

64772

64773

64774

64775

64777

-

-

-

-

-

-

-

-

-

-

-

Loading...

Loading...