508.366.1488 | www.semshred.com

18

5. Clean any excess debris from the transition area and vacuum all other loose debris.

6. Clean all surfaces inside and outside with the multi-purpose cleaning solution and a rag.

7. Vacuum any dust in the vacuum filter bin.

8. Wipe down the vacuum fan system with the multi-purpose cleaning solution and a rag.

Lubrication

Caution: Always de-energize the unit using proper lockout-tagout (LOTO) procedures when cleaning,

lubricating, or performing any other maintenance, troubleshooting, or repair.

For optimum performance, lubricate the unit regularly.

Tools and PPE Required:

• Cut resistant gloves, safety eyewear, and a face mask

• Grease gun with standard fitting and a flexible tube nozzle

• Non-flammable mineral oil in a spray container

Stage 1 cutting chamber lubrication:

• Frequency: Every 72 hours of operation

• Lubricant: Non-flammable mineral oil

• Lightly spray the non-flammable mineral oil onto the cutting heads.

Stage 2 cutting chamber lubrication:

• Frequency: Twice yearly or as needed

• Lubricant: Multi-purpose grease or

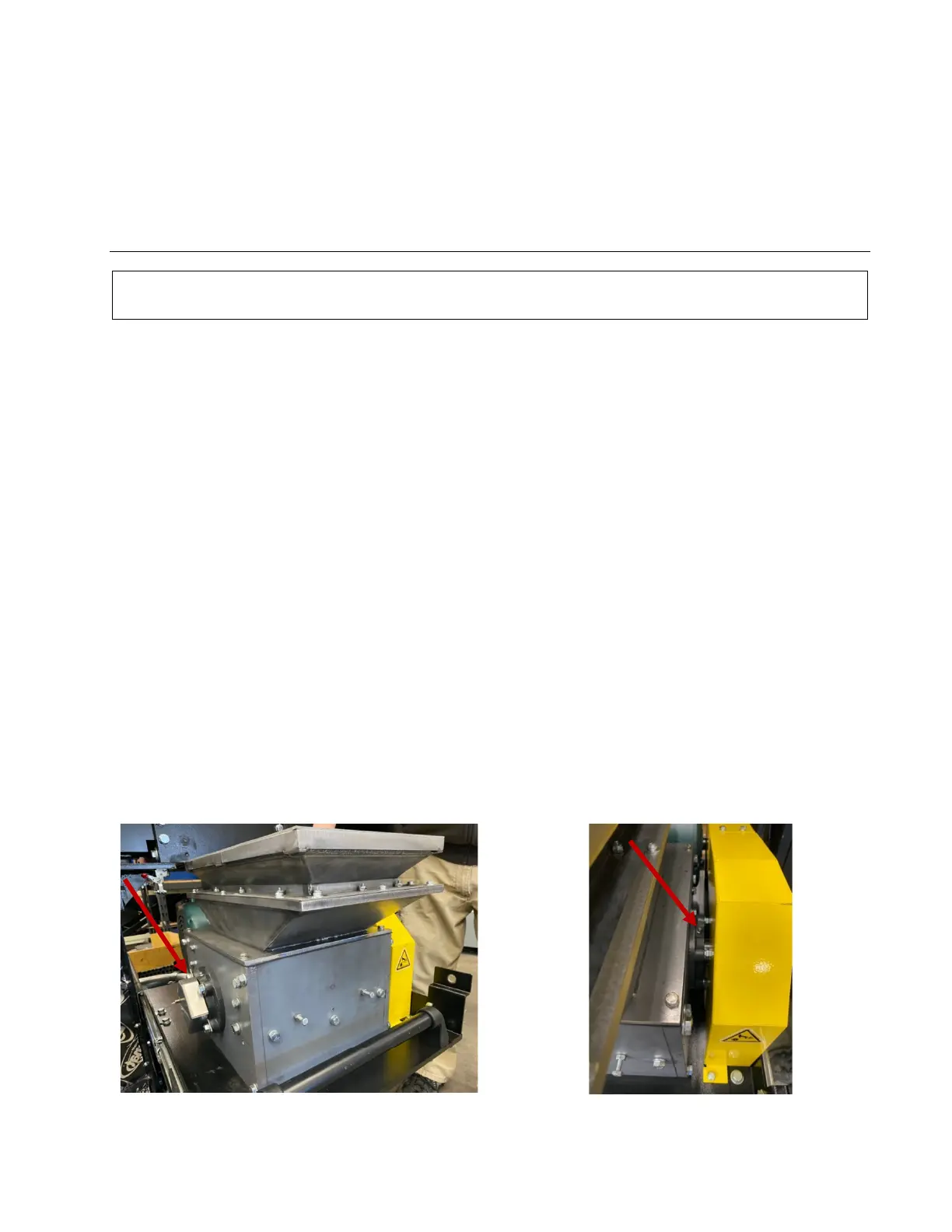

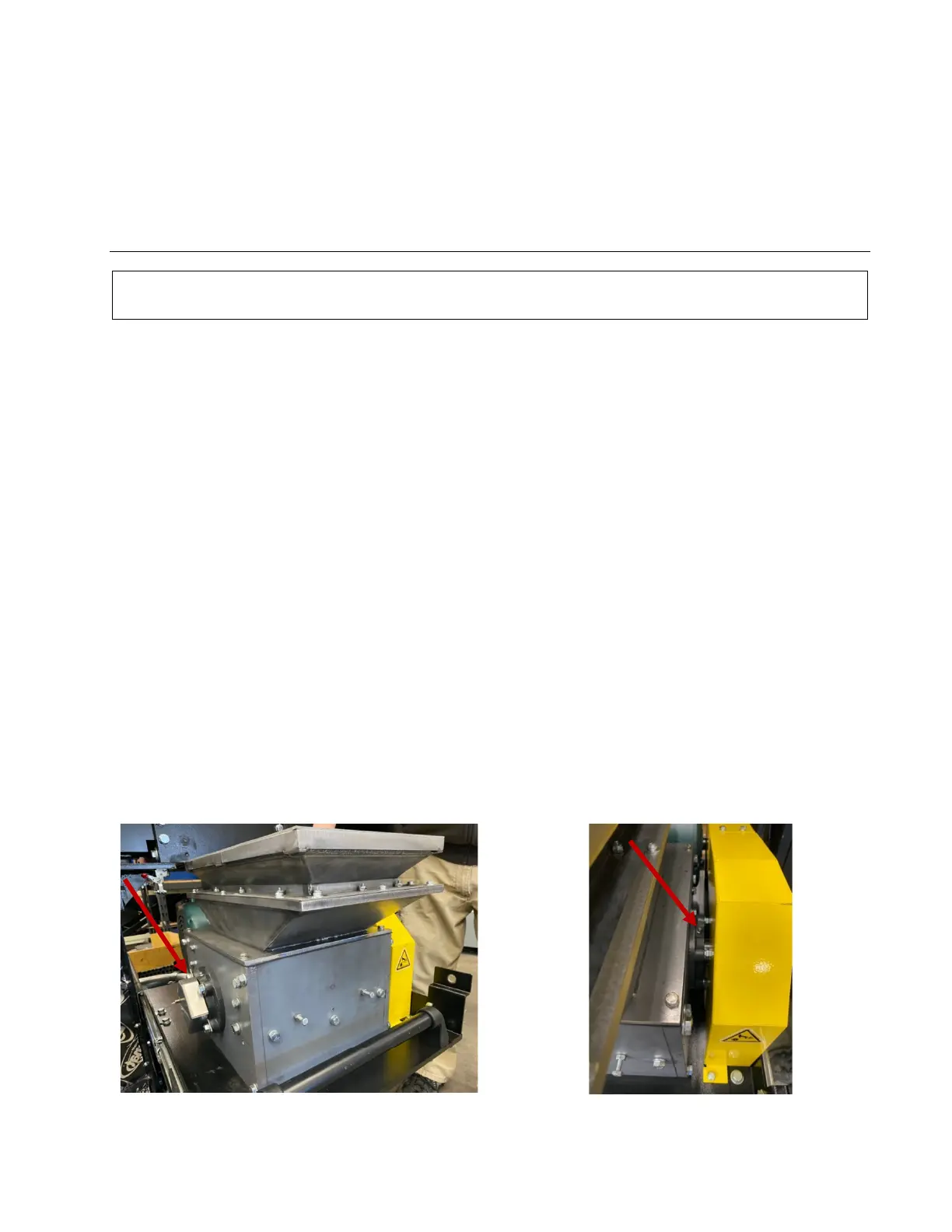

• Location: Grease fittings are located on top of the rotor bearings on each side of the Stage 2 cutting

chamber (Figure 9). Pull the drawer out for access.

• Pump 2-3 pumps on each fitting (Figure 9). Do not over-lubricate.

• Fan: None

Figure 9. Grease fittings on top of the rotor bearings

Loading...

Loading...