508.366.1488 | www.semshred.com

30

Changing the Rotor Knives

Caution: Always de-energize the unit using proper lockout-tagout (LOTO) procedures when cleaning,

lubricating, or performing any other maintenance, troubleshooting, or repair.

Caution: Always wear proper PPE, including cut resistant gloves, when accessing the cutting chambers.

Warning: Failure to sharpen or replace knives will result in excess dust, frequent jamming in the Stage 2

chamber, reduced throughput, excess vibration, and increased noise throughout the unit.

Re-sharpening: Knives can be re-sharpened 2-3 times provided they are not significantly damaged or worn.

Knives must be sharpened as a complete set (2 bed knives, 3 rotor knives). Contact SEM customer service

for details or for replacement knives.

Tools and PPE Required:

• Cut resistant gloves

• 7/16” and 1/2” wrench or socket wrench

• 5/16” Allen drive socket bit

• 4-6” socket wrench extension

• Torque wrench compatible with sockets listed above

• 0.005” feeler gauge

Frequency: Change the blades as needed, based on usage. Knife wear varies, depending on the material

being destroyed. In all cases, change the knives and return them for sharpening after no more than 25 hours

of usage to avoid potential jams and excessive dust.

Note: SEM highly recommends that this work be completed by SEM-trained technicians.

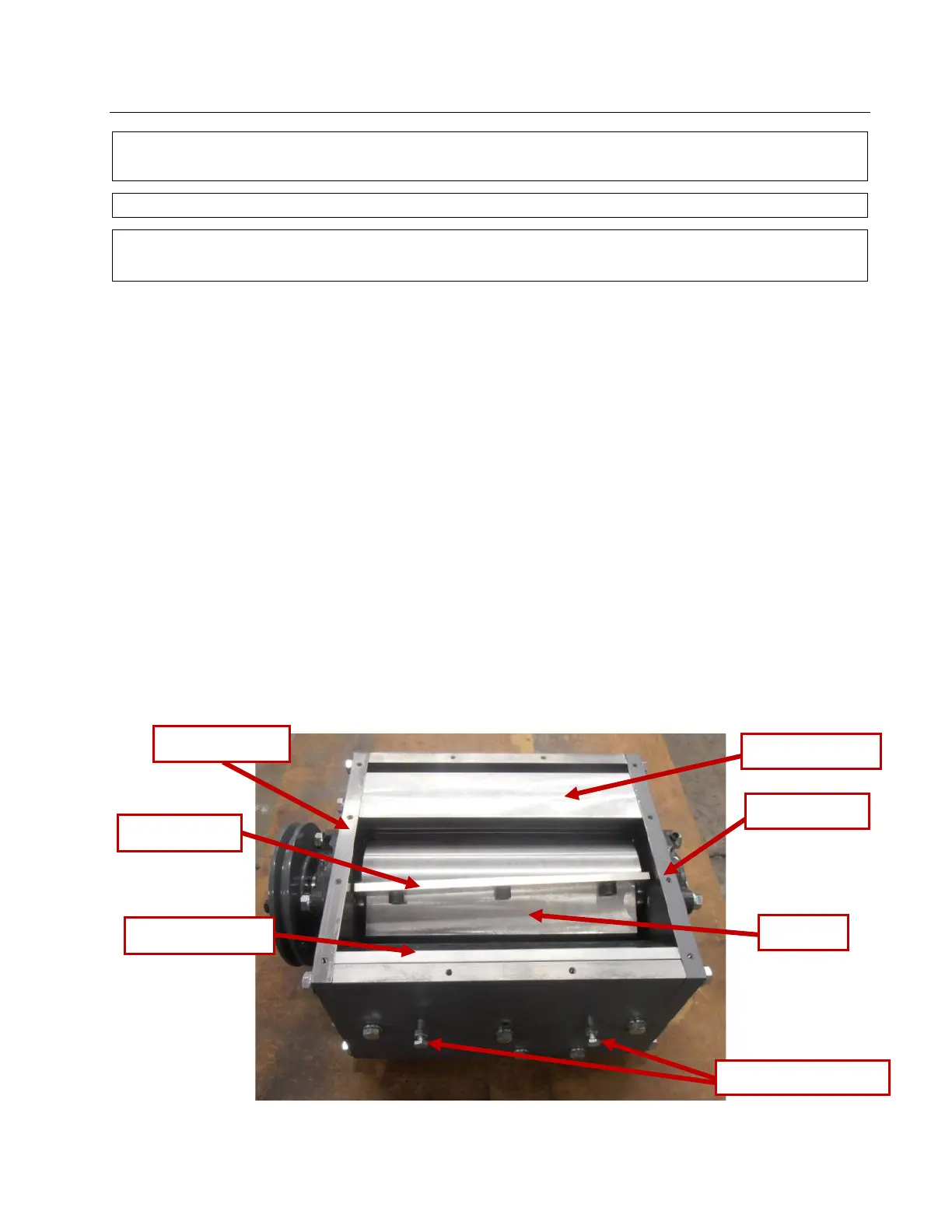

Figure 33. Chamber overview

Loading...

Loading...