508.366.1488 | www.semshred.com

29

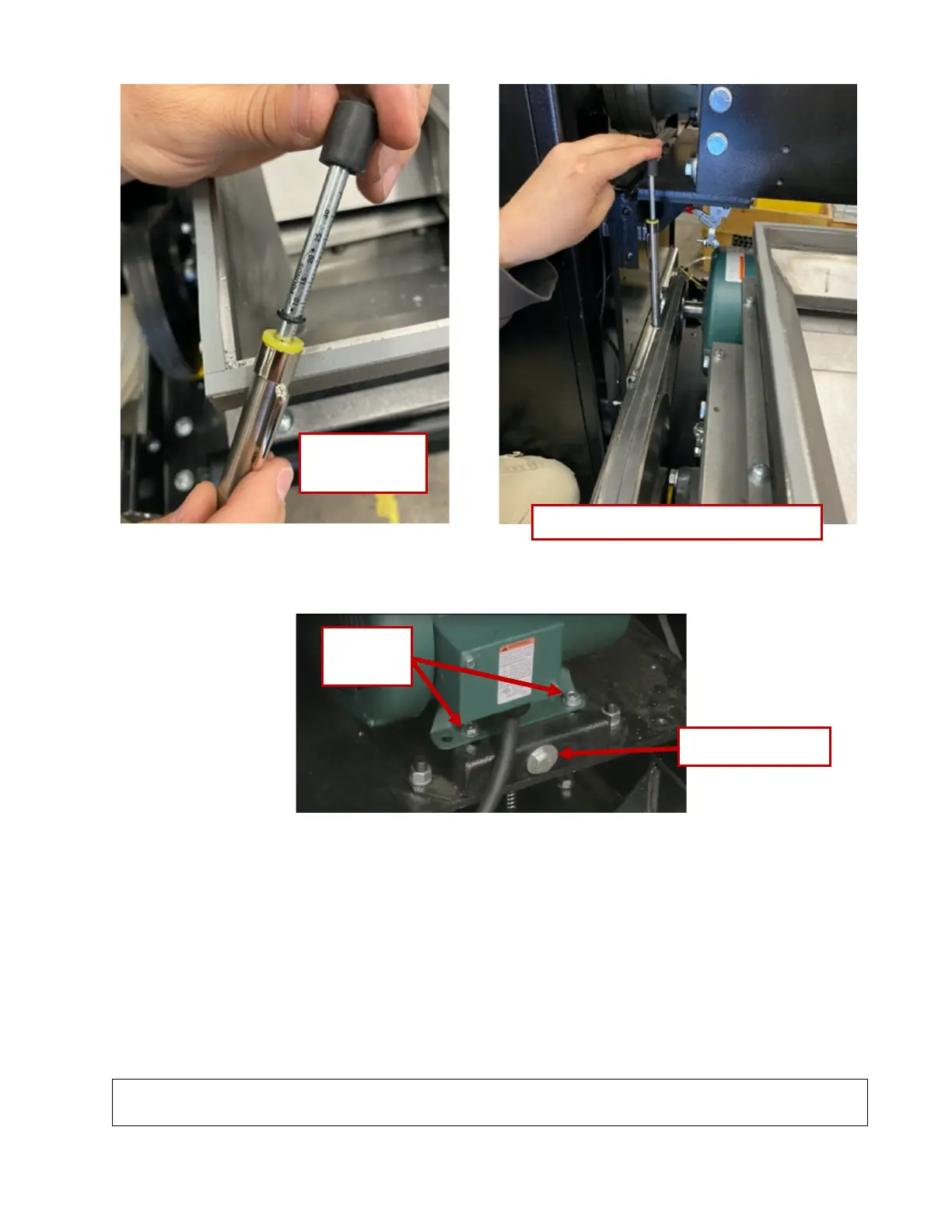

Figure 30. Correct pressure

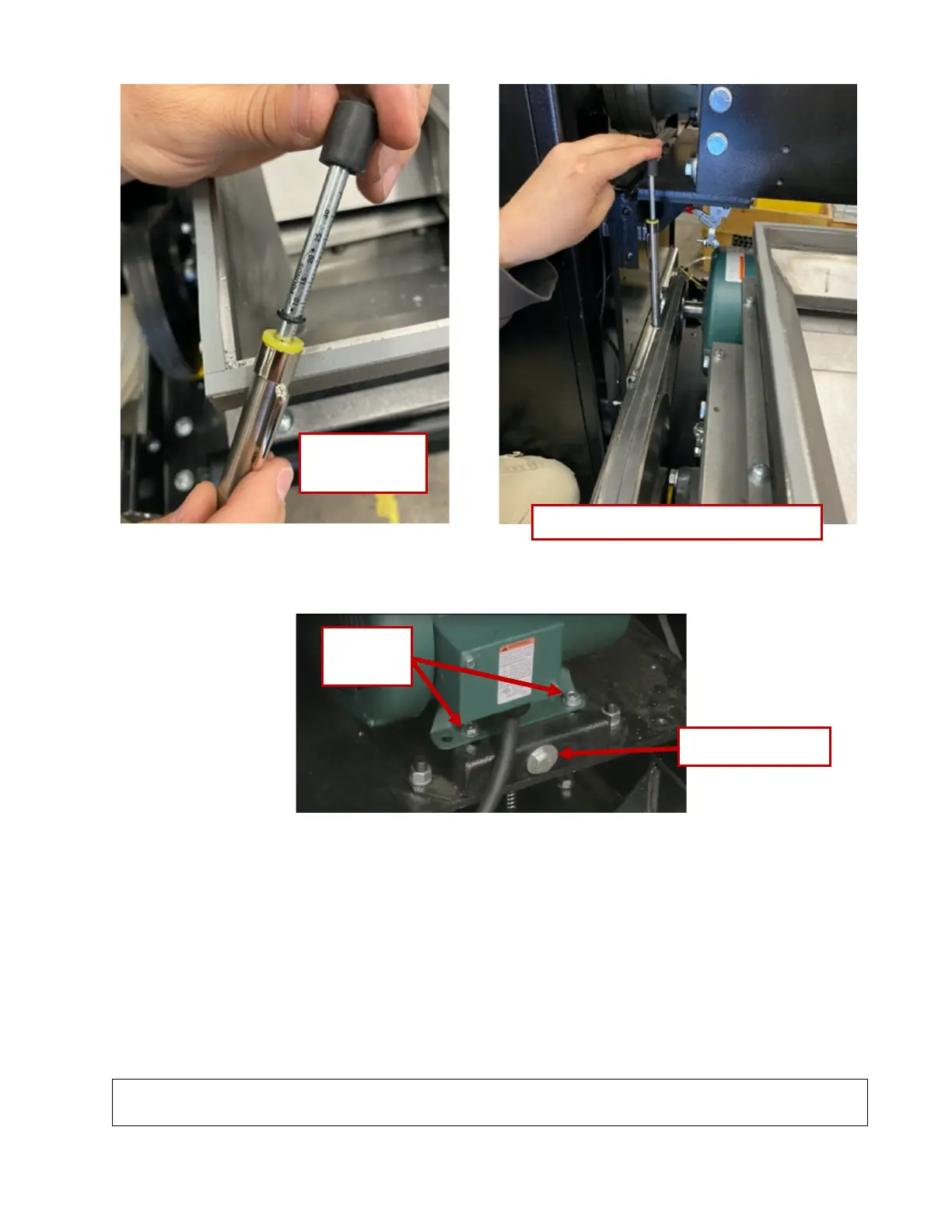

Figure 31. Applying pressure to belt

Figure 32. Tensioning adjustment

2. Loosen the four bolts that hold the motor. Figure 32 shows the two in the back. The other two are in the

front.

3. Use the tensioning bolt on the frame to adjust the belt tension:

clockwise to tighten, counterclockwise to loosen.

4. Adjust and check the tension until the proper tension is achieved.

5. Tighten motor mounting bolts.

6. Inspect the whole length of both belts for any damage.

7. Reinstall the belt guard.

Important: Check and tighten the belt (if required) after the first 10 hours of operation. After that, check

and tighten quarterly, as well as anytime a jam occurs. Change the belts annually or if they are damaged.

Apply perpendicular pressure

Loading...

Loading...