Section 2 Installation Instructions

Part Number 020005256 5/15 2-21

STARTING SYSTEM & DISPENSER

Upon completion of the beverage dispenser and / or

system installation, all tubing, dispenser, and system

components must be cleaned and sanitized prior to use.

NOTE: At installation equipment, dispensers, and tubing

get moved through many environments, dirt, dust,

chases, insulation, drywall, etc. It is an important

procedure and best practice to address cleaning to

deliver the best quality drink to your customer.

Clean and sanitize the water and syrup circuits

according to instructions provided in this manual. Clean

and sanitize the dispenser components according to

instructions provided in this manual. Consult and use

local health codes if a discrepancy occurs between this

manual and your local health codes.

Test Draw Temperature

Draw temperature test is only to be done after the

coldplate has completely chilled.

1. Operate one valve for about 15 seconds.

2. Take a temperature reading of the beverage on the

next 15 second draw. If the sample drawn is 40°F or

lower, go to the next step. If the beverage is higher

than 40°F, wait 10 minutes longer for the beverage

to attain the proper temperatures. Then repeat this

step.

3. When the beverage achieves the proper

temperature the valves syrup to water ratio (brix)

can be set.

4. Install flavor labels on the dispensing valve covers

then proceed to brix the valves.

Adjust Syrup to Water Ratio (Brix)

These are general brix instructions for beverage valves

using an S-tube syrup separator and high yield brix cup,

process may vary depending on valve manufacturer.

Refer to valve manufacturer for specific brix instructions.

1. Remove nozzle and syrup diffuser from valve.

2. Use an S-tube syrup separator to separate the syrup

dispense from the water by installing the rubber tip

snuggly over the diffuser.

3. Re-attach nozzle and diffuser with S Tube in place.

4. After nozzle has been re-attached, dispense a small

amount of product to fill up the S-tube.

NOTE: This is necessary to ensure an accurate reading.

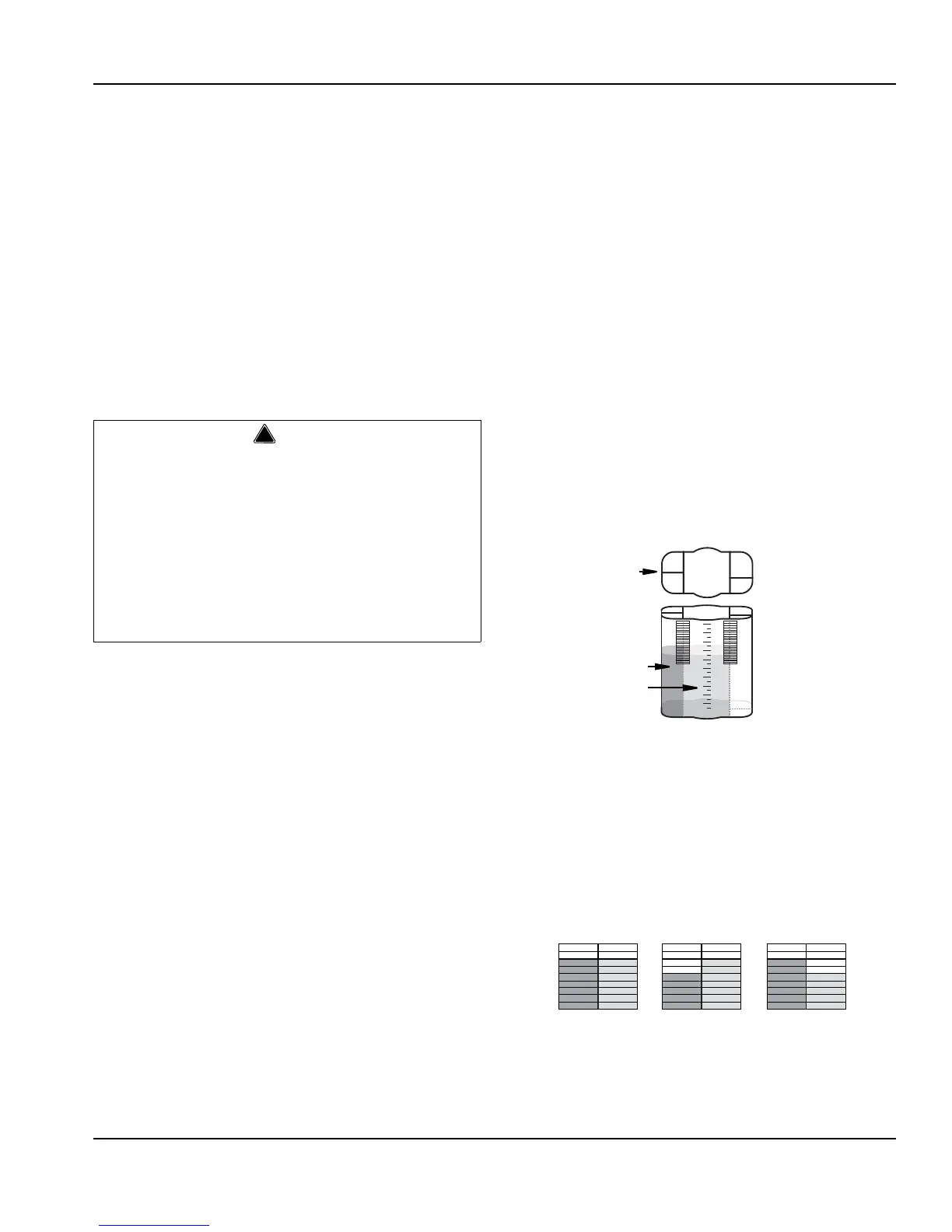

5. Position the large middle opening of the brix cup

under the valve. At the same time insert the free end

of the S tube into the proper syrup ratio chamber.

Verify what ratio is recommended for the product.

The diagram below illustrates a typical high yield

brix cup.

6. Dispense product until product reaches the grid on

the Brix cup.

NOTE: The water should be clear. If the water is not

clear, the S-tube has not been attached correctly to the

syrup diffuser, correct and repeat previous step.

7. Remove filled brix cup from dispenser and tap on

counter 3 times. Place on flat surface.

8. Look a the grid lines. The water and syrup levels

should be + / - 2 bars of each other.

9. Adjust dispensing valves for water-to-syrup ratio

(brix) as recommended by the syrup distributor.

10. Repeat these steps for each product that will be

dispensed.

Carbon Dioxide (CO

2

) displaces oxygen. Exposure to a

high concentration of CO

2

gas causes tremors, which are

followed rapidly by loss of consciousness and suffocation.

If a CO

2

gas leak is suspected, particularly in a small

area, immediately ventilate the area before repairing the

leak. CO

2

lines and pumps should not be installed in an

enclosed space. An enclosed space can be a cooler or

small room or closet. This may include convenience

stores with glass door self serve coolers. If you suspect

CO

2

may build up in an area, venting of the B-I-B pumps

and / or CO

2

monitors should be utilized.

6:1

5.5:1

8.5:1

5:1

WATER

5.5

to 1

8.5

to 1

10

OZ.

SYRUP

WATER

SYRUP

RATIOS

High Yield Brix Cup

SYRUP

WATER

SYRUP

WATER

SYRUP

WATER

Loading...

Loading...