Section 3 Operation

Part Number 020005256 5/15 3-3

CO2 SUPPLY

Note: CO

2 inlet for the internal carbonator is located

with the cold plate inlet lines.

(See plumbing diagram for exact plumbing location)

•CO2 pressure to the BIB pump is 60 to 75 psi.

• DI-1522, 2323 & DIL-2323 CO

2 pressure to the internal

carbonator is 75 psi.

• For ambient carbonated systems the CO

2 pressure to the

carbonator should be set at 100 PSI

• "Optional" A low CO

2 alarm is available on all internally

Carbonated DI series units. A RED low CO

2 light mounted

to the tower will illuminate when the CO

2 supply for the

cabonator tank starts running low.

A CO

2 cylinder delivers carbon dioxide (CO2) gas through an

adjustable CO

2 regulator to the syrup BIB pump and also to

an internal carbonator. Plain water also enters the internal

carbonator tank, and is carbonated by the regulated CO

2 gas

pressure. When a dispensing valve is opened, CO

2 pressure

exerted within the syrup BIB pump propels syrup from the

BIB, through the beverage coils, and into the dispensing

valve. Carbonated water is forced from the carbonator tank by

CO

2 pressure which pushes cold carbonated water into the

dispensing valve resulting in a carbonated drink being

dispensed. A non-carbonated drink is dispensed in the same

manner as a carbonated drink with the exception that plain

water is substituted for carbonated.

The carbonator is replenished when the carbonated water

level inside the tank drops, which in turn automatically starts

the carbonator water pump. When the water level inside the

tank has been replenished, carbonator water pump will stop.

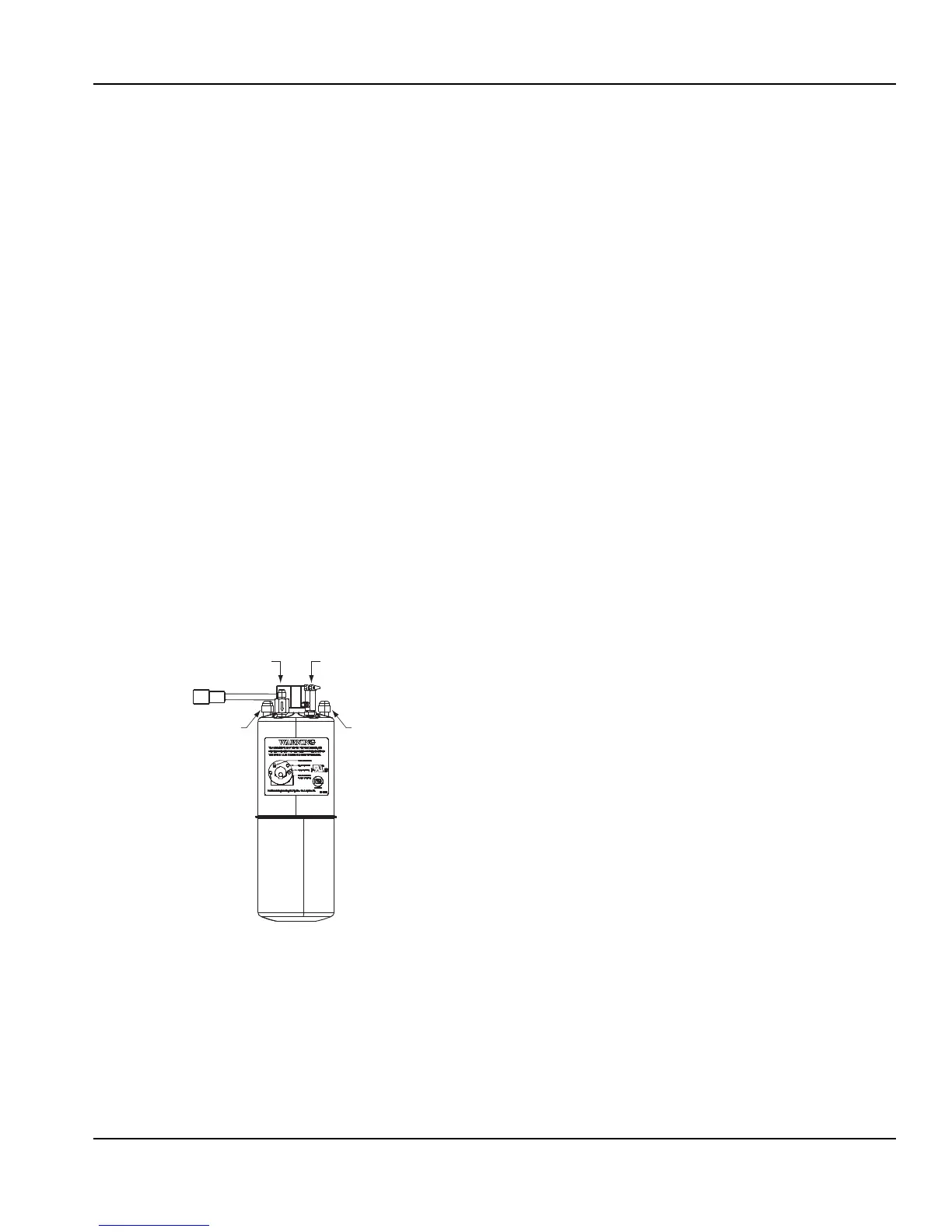

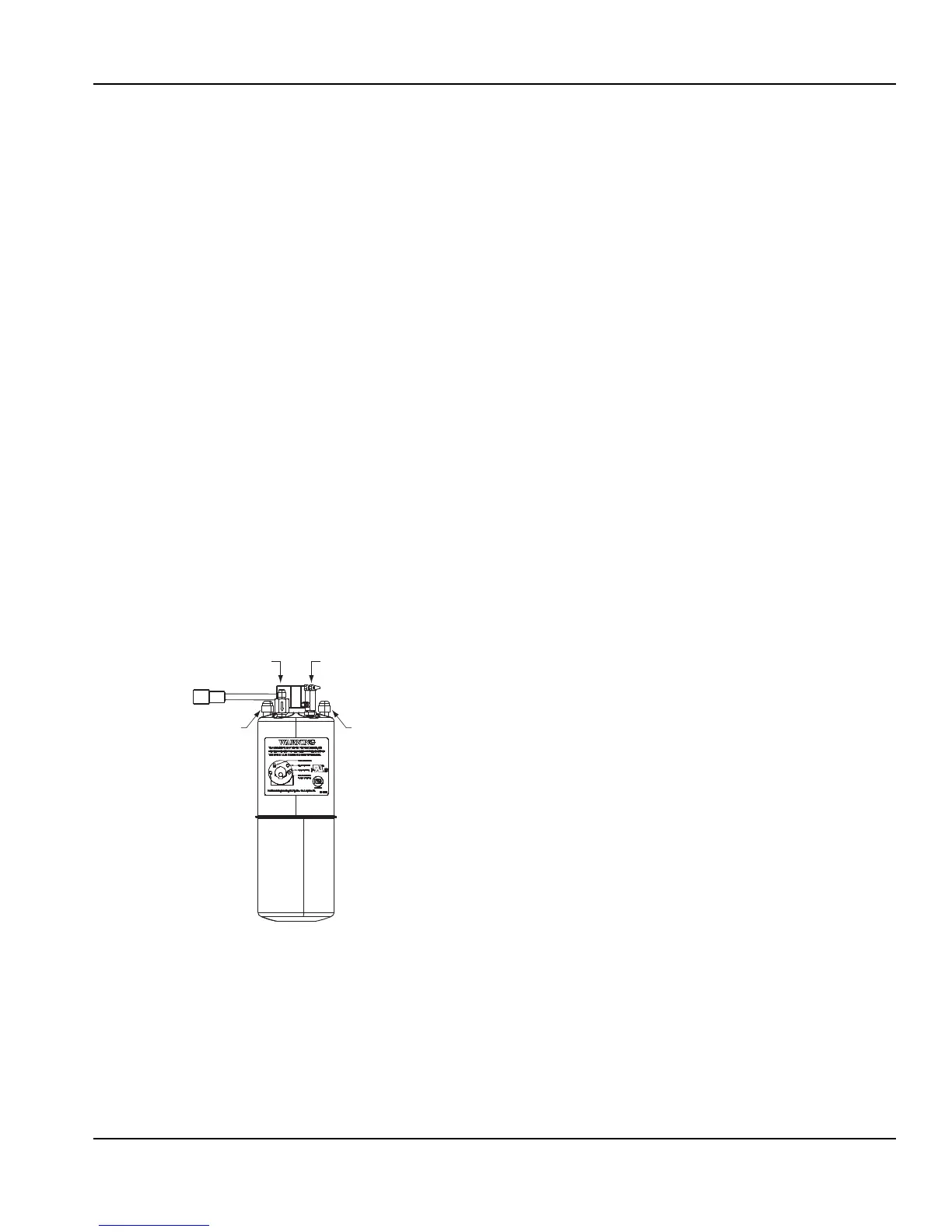

CARBONATED WATER

Carbon Dioxide (CO

2

) leaves the storage tank and

arrives at the carbonator tank through the gas inlet.

Water supply enters the carbonator pump inlet at regular

street water line pressure (minimum 20 PSI, maximum

80 PSI, dynamic or flowing pressure). The water pump

increases the pressure of the water, which allows the

water to flow into the carbonator tank. The CO

2

and the

water mix together in the carbonator to produce the

carbonated water that is then sent to the soda dispenser.

The agitation of the water and CO

2

together in the tank

under high pressure creates the soda water. The quality

of carbonation (percent of CO

2

mixed in the water)

increases as the water temperature decreases and

exposure time increases.

The water level in the carbonator tank is controlled by a

water level control in the tank. This control turns the

pump motor off and on to maintain a preset level of liquid

in the tank. The water level control may be electronic

probes or a mechanical float.

SYRUP DELIVERY SYSTEM

Your syrup location can vary depending on the volume of

beverages served and ease of accessibility. Your

beverage system may set in a back storage room or

under the counter of the dispenser. Configurations are

almost limitless. Check the temperatures expected for

the storage location. Adverse temperatures can affect

the storage and quality of beverage products. It is

recommended the temperature of storage location

should not fall below 40°F (4°C) or rise above 90°F

(32°C).

WATER SUPPLY

For internal carbonated systems:

Incoming water supply minimum of 40 and maximum of

55 psi. If incoming (static) water supply is over 55 psi

you have to install a water regulator. If incoming

(dynamic) water pressure is under 40 psi a water

booster is required.

NOTE: The incoming water supply for the carbonator,

which is the pre-chill inlet on the plumbing diagram, must

first be ran through the carbonator pump which is

located on the carbonator pump deck (power supply).

Carbonated

Water Outlet

Pressure

Relief

CO

2

inlet

120 psi max

Water Inlet

Loading...

Loading...