Section 4 Maintenance

Part Number 020005256 5/15 4-3

Sanitizing

BEVERAGE SYSTEM CLEANING

Sanitize the beverage system at initial start-up as well as

regularly scheduled cleaning. The drain pan must be in

place under soda valves, to carry away detergent and

sanitizing agents that will be flushed through valves.

BAG-IN-BOX SYSTEM SANITATION

The procedure below is for the sanitation of one

syrup circuit at a time. Repeat to sanitize additional

circuits.

You will need the following items to clean and sanitize

the Bag-in-Box (BIB) beverage system:

• Three (3) clean buckets

• Plastic brush or soft cloth

• Mild detergent

• Unscented bleach (5% Na CL O) or

Commercial sanitizer

• Bag-In-Box bag connector

1. Prepare the following in the buckets:

• Bucket 1 — warm to hot tap water for rinsing.

• Bucket 2 — mild detergent and warm to hot

water.

• Bucket 3 — mix a solution of unscented bleach

(5% Na CL O) or commercial sanitizer and warm

to hot water. Mixture should supply 100 PPM

available chlorine (1/4 oz. bleach to 1 gallon

water).

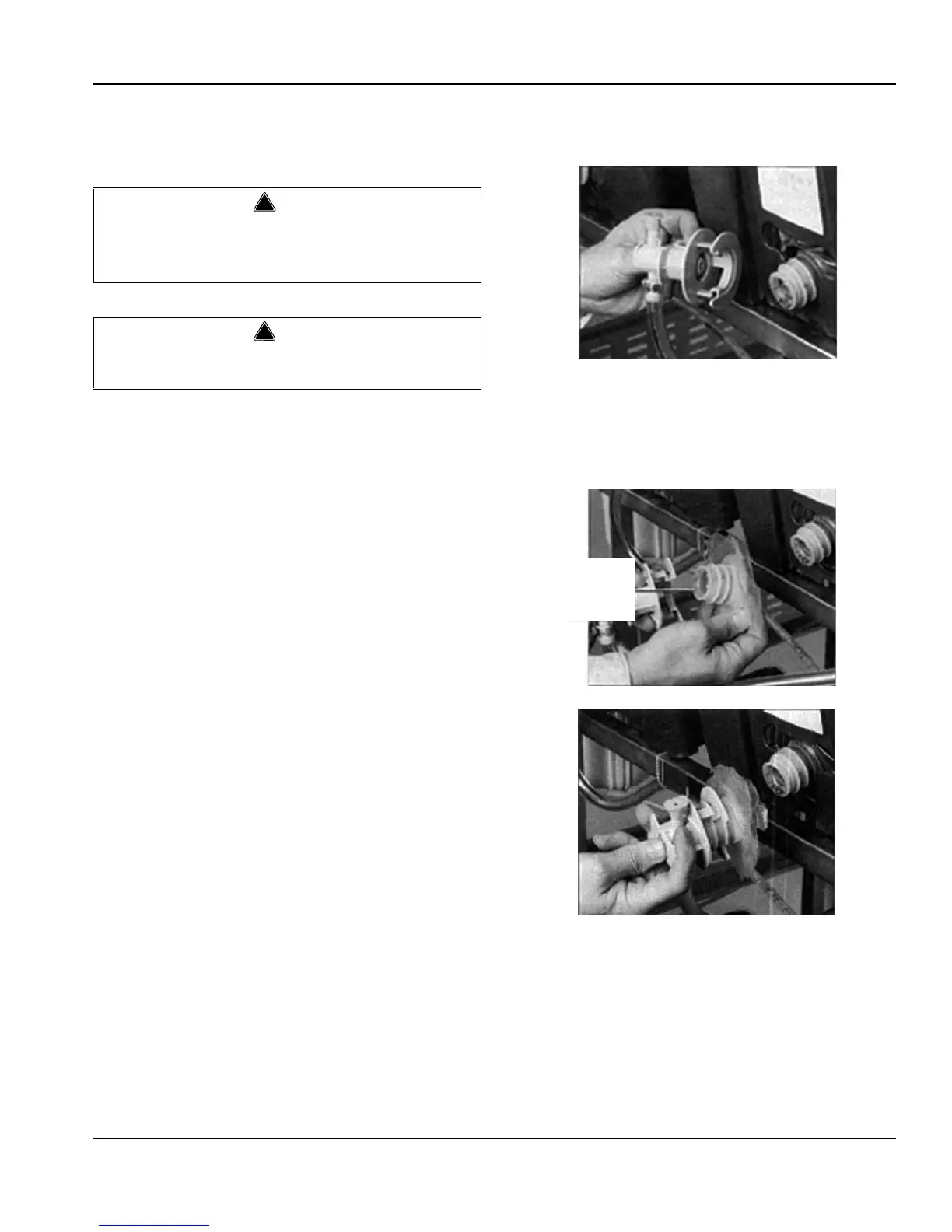

2. Disconnect the “syrup-line side” of the bag-in-box

connector.

3. Rinse connector with warm tap water.

4. Connect syrup connector to BIB connector and

immerse both into Bucket 1. A “bag-side” connector

can be created by cutting the connector from an

empty disposable syrup bag.

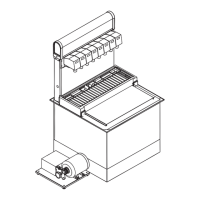

5. Draw rinse water through system until clean water is

dispensed. Most beverage valves allow the syrup

side to be manually activated by depressing the

syrup pallet.

6. Connect Bucket 2 to system.

7. Draw detergent solution through system until

solution is dispensed.

8. Repeat steps 2-7 until all syrup circuits contain

detergent solution.

Flush sanitizing solution from syrup system.

Residual sanitizing solution left in system could

create a health hazard.

When using cleaning fluids or chemicals, rubber

gloves and eye protection must be worn.

Loading...

Loading...