Operation Section 3

3-2

Part Number 020005256 5/15

PRE-MIX DROP-INS

Pre-mix fountain dispensing consists of a container of

beverage ready for dispensing, beverage delivery

system, carbon dioxide (CO

2) propellant, beverage

cooling system, and dispenser. We shall discuss each

component of this type of system within the context of

this manual.

The major advantage of a pre-mix system over most

other types is its flexibility. This flexibility is the ability to

go anywhere. Many pre-mix systems will operate without

electric power or separate water supply. Most drop-ins

are manufactured for post-mix. Unless otherwise stated,

operation and installation instructions are for post-mix.

STANDS

Stands are designed to accommodate drop-in ice bins

and to provide an enclosure for carbonators. See

instructions provided with those items for proper

installation and connections.

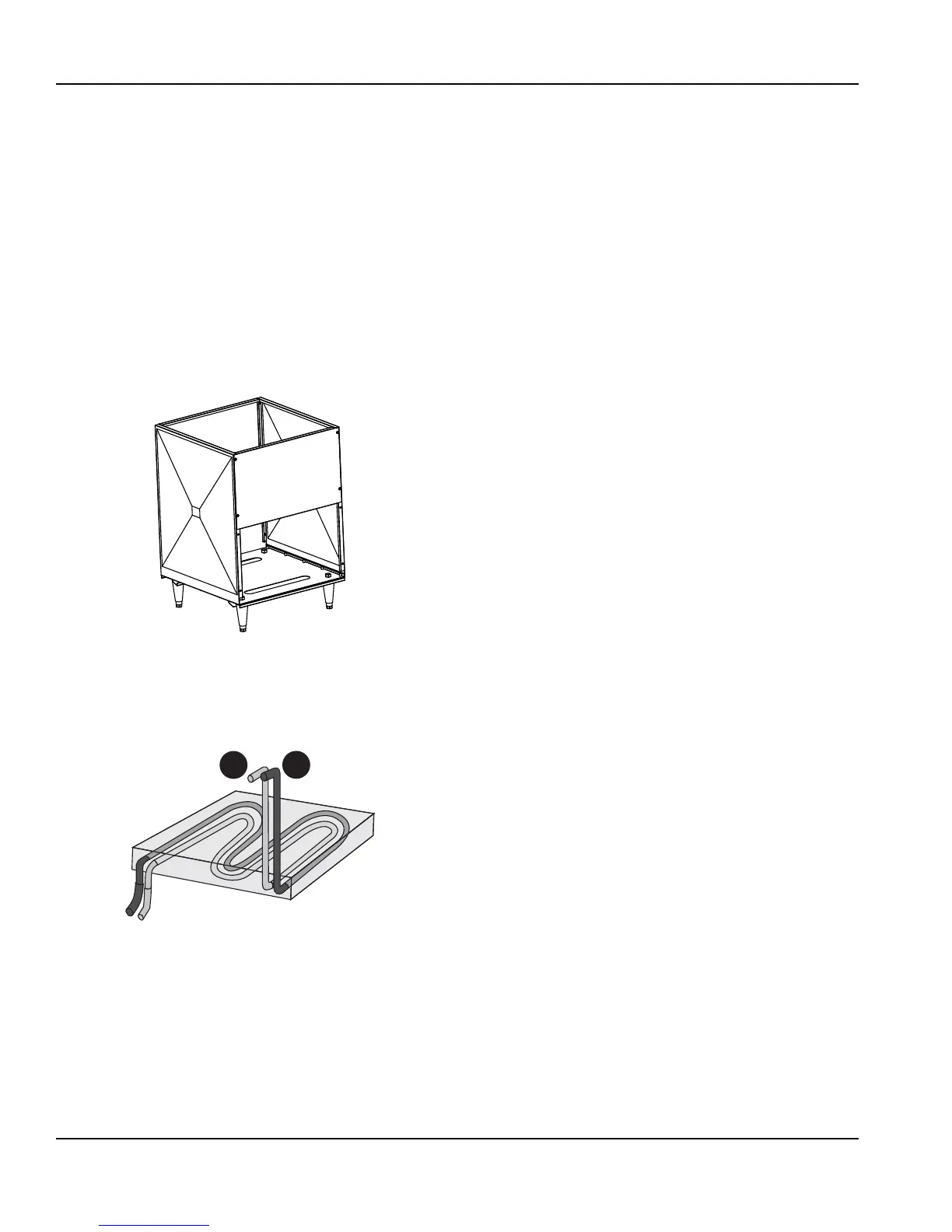

COLD PLATE BEVERAGE COOLING

A cold plate is a block of aluminum with serpentine

stainless steel tubes molded inside the aluminum block.

The cold plate is approximately the same length and

width as the bottom of the dispenser bin. Ice sits on top

of the cold plate and cools the cold plate. The stainless

steel tubes inside the cold plate carry carbonated water

(soda water), noncarbonated water (plain water) and

syrup to the beverage valves. While flowing through the

stainless steel tubes in the cold plate, water and syrup

are chilled to serving temperature.

UNIT INSPECTION

This section covers unpacking, inspecting, selecting location,

installing the unit, and preparing for operation. Thoroughly

inspect the unit upon delivery. Immediately report any damage

that occurred during transportation to the delivery carrier.

Request a written inspection report from a claims inspector to

document any necessary claim.

1. After the unit has been unpacked, remove the keys. The

key will be needed to perform brixing of valves. Hold onto

the keys until such time to forward them to the respective

owner/operator. Remove tape (which secures grid in

place in drain pan) from grid and other packing material.

2. Make sure all items are present and in good condition.

Loose shipped items in the carton include the drain kit

parts and the instructions.

3. Inspect unit for any external damages.

If you have an internal carbonated unit the unit is pre-plumbed

at the factory. The inlets for CO

2 and water are located behind

the splash panel. There are two inlets for water and one inlet

for CO

2. If you have questions refer to the plumbing diagram

on your equipment.

BEVERAGE VALVES

Post-mix beverage valves are designed to precisely meter the

flow of both water and syrup to obtain the proper mixing ratio.

The syrup and soda water components of the post-mix

beverage are mixed as they leave the beverage valve.

Loading...

Loading...