Servomex 2700 Quickstart Manual

Servomex 2700 Quickstart Manual

16

The following procedure is executed on automatic calibration.

• The relay assignments are checked to ensure that the

required relay contacts have been assigned as solenoid

valve drives. If the relay assignments are incorrect then the

autocalibrate will abort with an appropriate error message

being displayed for 5 seconds.

• The required calibration gases will be admitted to the

sensor head in turn. When each gas is admitted the

process will wait for a user-defined flushing time before

recording the calibration response values. Between 1 and 3

gases will be admitted depending on the calibrations to be

performed.

• The new calibration parameters are calculated and

compared with the existing stored values. If the change in

the calibration parameters is outside of the specified

tolerance values then the autocalibration is aborted, a fault

is raised and the calibration values are not updated.

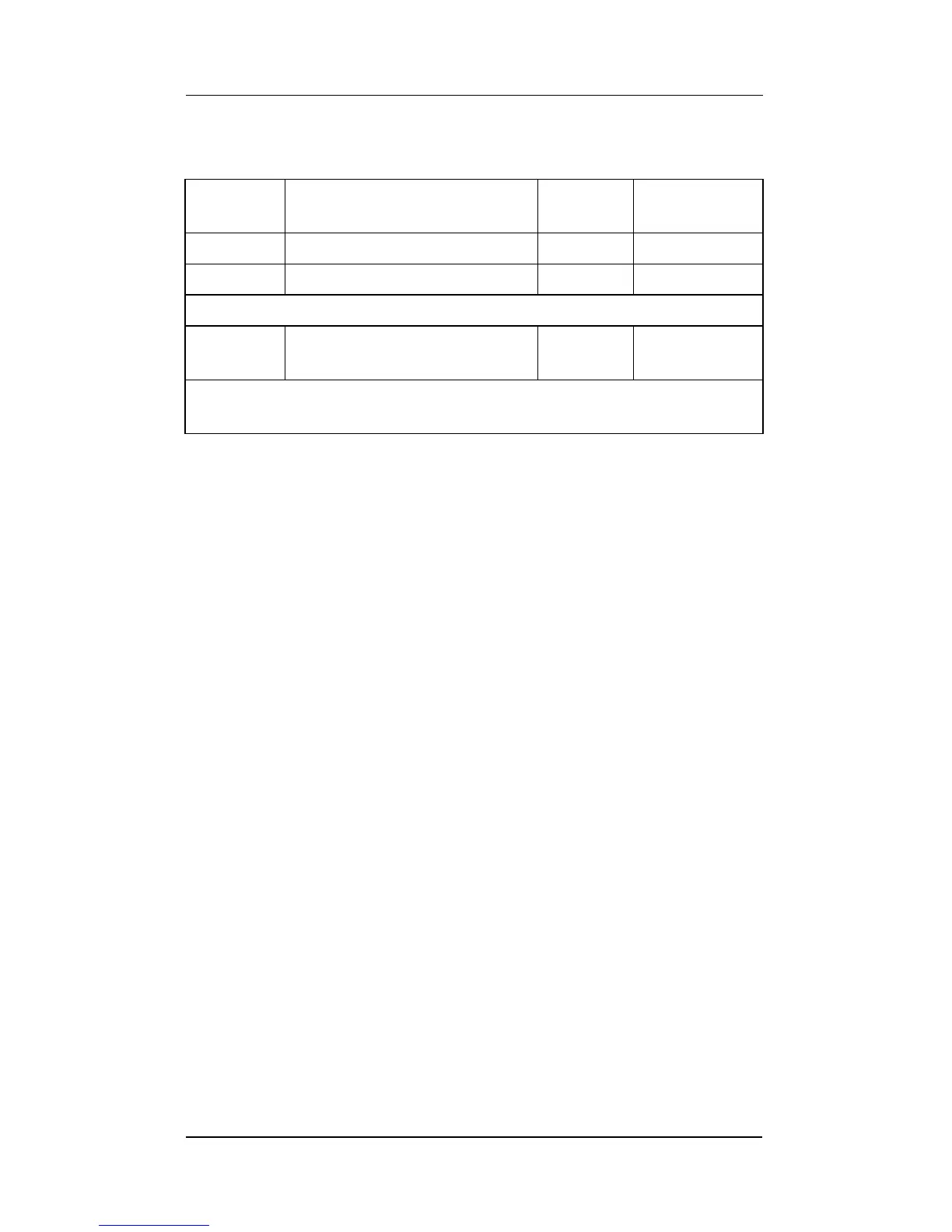

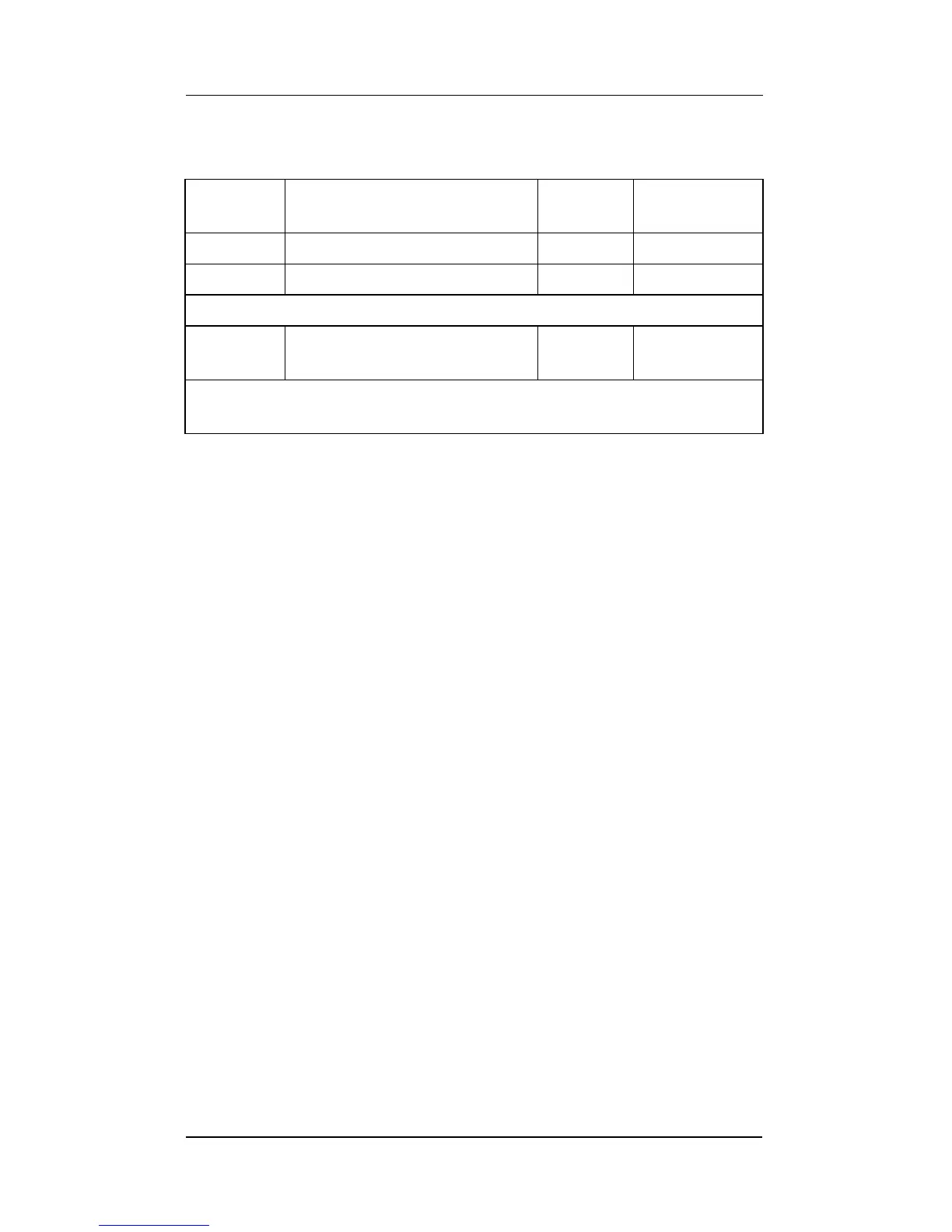

Table 1: Recommended calibration gas

Solenoid

number

Gas composition Oxygen

sensor

Combustibles

sensor

GAS 1 Zero air (20.95%(v) O

2

)HIGHLOW

GAS 2 0.3%(v) O

2

balance N

2

*LOW N/A

* gas composition can be between 0.25% and 2.5% O

2

in N

2

GAS 3 1000ppm(v) CO balance

air**

N/A HIGH

** gas composition can be between 500ppm and 1000ppm

CO balance air for a 1750702 sensor.

Loading...

Loading...