Setra FLEX Operating Instructions

12

Phone: (800) 257-3872 | Fax: (978) 264-0292 | www.setra.com

Considerations to Avoid Kinked or Damaged Tubing

Pull tubing runs in a manner that protects the tubing from

being damaged, cut, or crimped. Any break or bend in the

tubing may affect the integrity of the pressure signal. DO

NOT TIGHTEN STRAIN RELIEFS at the electrical boxes so

that they crimp the tubing. Leave the strain reliefs open

enough so that the tubing can slide in and out of the

box with a few inches of play. Prior to use, tape the open

ends of the tubes closed to prevent contamination during

construction.

DuringnalinstallationofthePressurePickupPorts,use

the included clear spring-wound adapters between the

nylon wall tubing and the back of the Pressure Pickup

Port, (as shown below). This will ensure when the port is

mounted to the wall that the tubing assembly does not

crimp inside the electrical box. Careful observation should

be made of how the tubing gets pushed back into the wall

fornalfaceplatemounting.

In a similar manner, mount remaining Pressure Pickup

Ports and the FLEX unit if using an on-board sensor.

Use of External Pressure Sensors

If FLEX is being used exclusively with external pressure

sensors, or in combination with an on-board sensor, the

external sensors require no tubing runs to the FLEX unit

itself. Instead, the external sensors will be separately

mounted, plumbed and wired. Only the wire for the analog

output of that sensor(s) will be run to the FLEX unit.

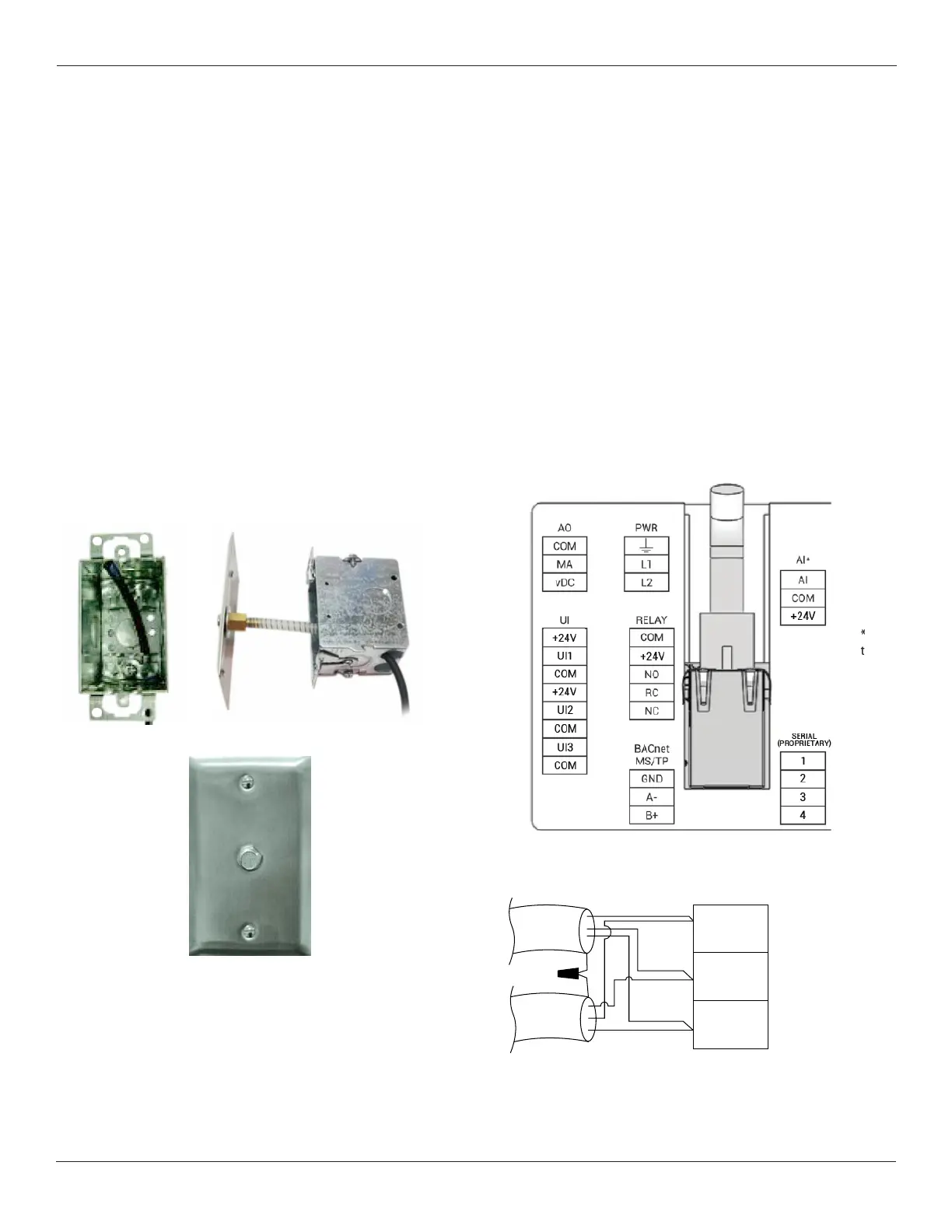

Wiring the FLEX Main Unit

The back of the FLEX unit has terminal blocks labeled

with their function. Universal inputs, marked “UI” will be

conguredforeitherAnalogInputsorDigitalInputsinthe

FLEXcongurationsetup.

Power

The 3-pin power connection for FLEX is labeled “PWR” on

the rear of the unit.

1. Pull off the removable PWR terminal block

2. Connect the 24 VAC lines to L1 and L2

3. Connect a ground wire to the ground terminal (if

provided)

4. Push the removable terminal block back into the PWR

connection

FLEX operates at 18-30 VAC, 50/60 Hz, and consumes 10

W nominal, 13 W maximum.

BACnet MS/TP Detail

*AI for on-board

transducer or

general AI input

B (+)

A (-)

GND

DATA +

DATA -

Loading...

Loading...