AR-M256/M257/M258/M316/M317/M318/5625/5631 SIMULATION 8 - 7

Operation/procedure

Select the load to be checked with the 10-key, and press the [START] key.

The motor for 10sec, the solenoid ON for 500msec, OFF for 500msec.

(20 times)

Note: Executable only when the RSPF is installed.

Operation/procedure

Used to display the operations of sensors and detectors in the finisher

section.

The active sensors and detectors are highlighted.

When AR-FN5A is installed

When AR-F14N is installed

When AR-F14N/Punch unit is installed

Note: Executable only when the finisher is installed.

Operation/procedure

Select the load to be checked with the 10-key, and press the [START] key.

The finisher main motor operates for 10sec, the staple motor 5 times,

the tray lift-up motor one reciprocating operation, other motors max. 20

reciprocating operations from the home position, the solenoid repeats

500msec ON and 500msec OFF 20 times.

The staple operation motor operates only when there is no cartridge

installed.

When AR-FN5A is installed

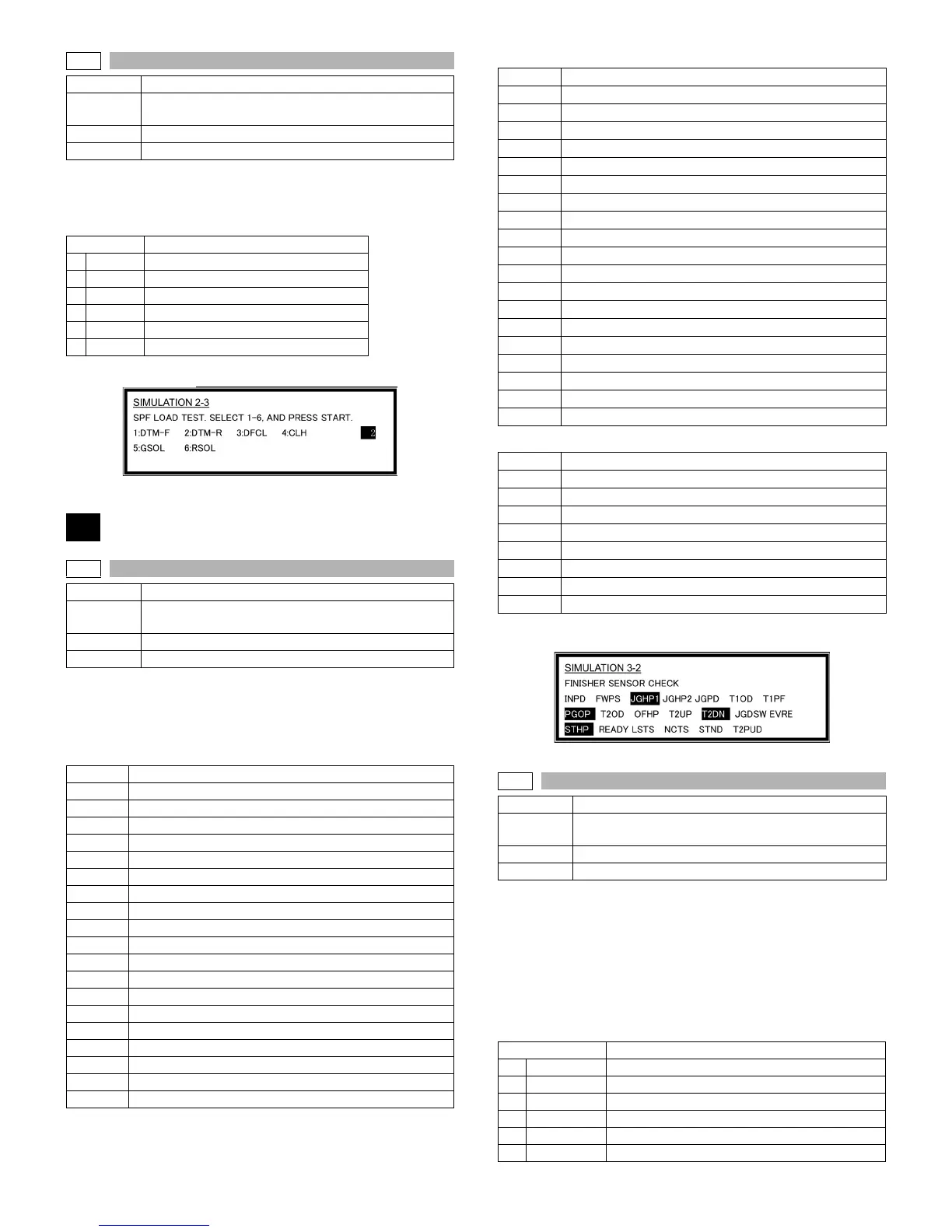

2-3

Purpose Operation test/check

Function

(Purpose)

Used to check the operation of the loads in the RSPF

unit and the control circuits.

Section RSPF

Item Operation

Item Content

1 DTM-F RSPF motor forward rotation

2 DTM-R RSPF motor reverse rotation

3 DFCL RSPF paper feed clutch

4CLH RSPF PS clutch

5 GSOL Document exit gate solenoid

6 RSOL Document exit pressure solenoid

3

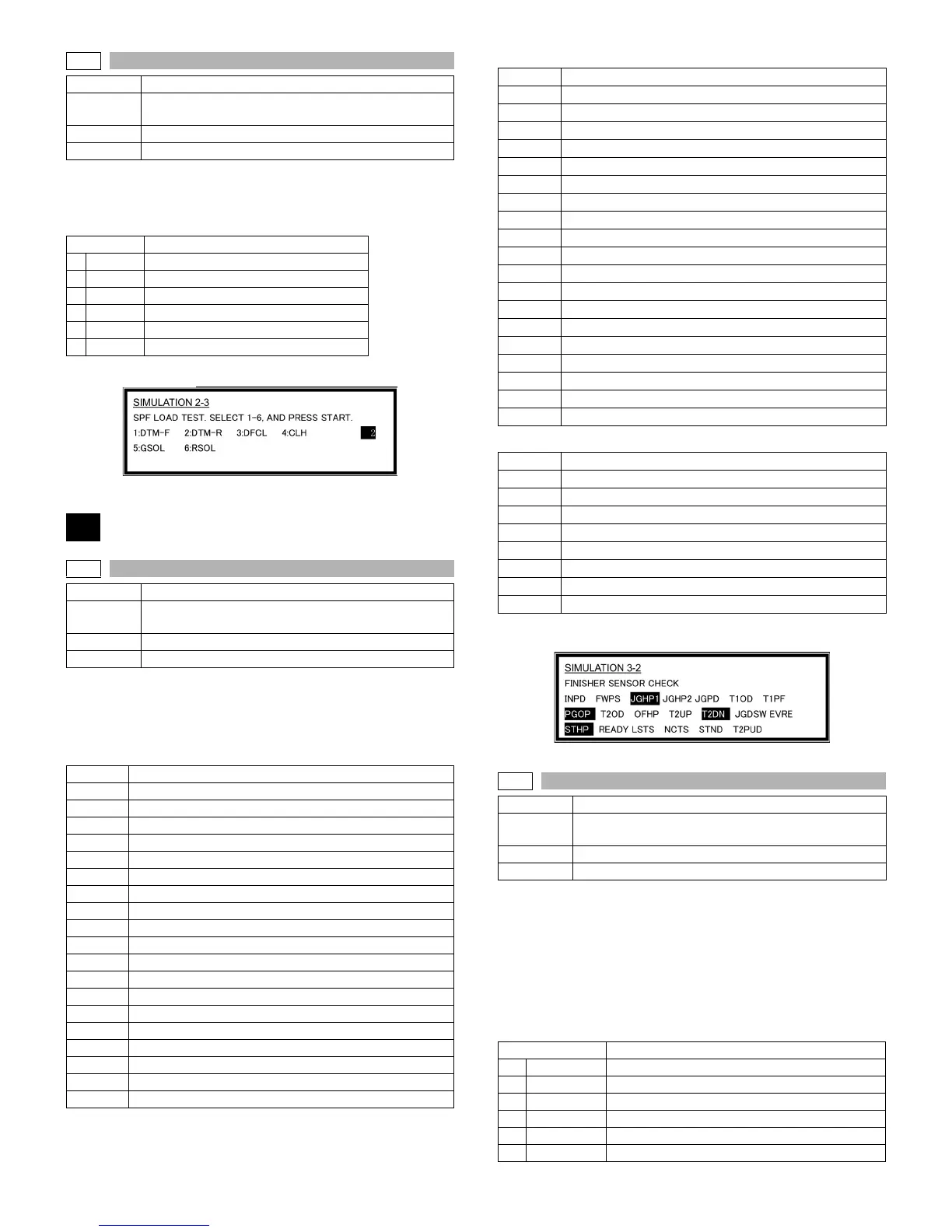

3-2

Purpose Operation test/check

Function

(Purpose)

Used to check the operation of sensor and detector in

the finisher and the related circuit.

Section Finisher

Item Operation

INPD Finisher paper entry sensor

FWPS Paper width sensor

JGHP1 Side guide plate HP sensor

JGHP2 Rear edge plate HP sensor

JGPD Tray paper empty sensor

T1OD 1st tray exit sensor

T1PF 1st tray paper full sensor

PGOP JAM processing PG open/close detection sensor

T2OD 2nd tray exit sensor

OFHP Offset HP sensor

T2UP Tray position sensor (upper)

T2DN Tray position sensor (lower)

JGDSW Tray jam processing interlock

EVRE Lift-up drive control sensor

STHP Staple HP sensor

READY Self priming sensor

LSTS Staple empty sensor

NCTS Cartridge empty sensor

STND Staple supply cover open/close sensor

T2PUD 2nd tray upper surface sensor

FSSS Stapler safety switch

FJS Joint switch

FFDSW Front door switch

FTCS Upper cover sensor

FFDS Front door sensor

FSPS Self prime sensor

FSUC Stapler connection detection

FSS Stapler sensor

FSTHPS Stapler HP sensor

FSHPS Slide HP sensor

FLE Lift lock sensor

FLLLS Lift lower limit sensor

FULS Lift upper limit sensor

FFE Book making clock sensor

FFES Book making paper sensor

FFRHPS Book making roller HP sensor

FFHPS Book making HP sensor

FFPS Book making position sensor

FSLS Paper surface sensor

FBES Tray paper sensor

FPE Punch motor encoder

FPSHPS Punch side resist home position

FPUC Punch connection detection

FPDS Punch dust sensor

FPDSS4 Punch side resist sensor 4

FPDSS3 Punch side resist sensor 3

FPDSS2 Punch side resist sensor 2

FPDSS1 Punch side resist sensor 1

FPTS Punch timing sensor

3-3

Purpose Operation test/check

Function

(Purpose)

Used to check the operation of the load in the finisher

and the control circuit.

Section Finisher

Item Operation

Item Content

1 JGM1 Side guide plate drive motor

2 JGM2 Rear edge plate drive motor

3 FM-600 Finisher main motor (600dpi)

4 FM-1200 Finisher main motor (1200dpi)

5 EVM Tray lift-up motor

6 OFM Tray offset motor

Loading...

Loading...