2 Installation Conditions

LCMS-8045/8050 Pre-Installation Requirements

10

2.9 Gas

A nitrogen gas is used as the nebulizer/drying gas, a dry air is used as the heating gas and Ar (Argon) is used as the CID gas.

As for the gas source of supply of the nitrogen/dry air, use of a nitrogen/dry air gas generator is recommended (*1,2).

Please consult us when using a customer's facility (e.g. a centralized piping, a liquid nitrogen, a gas cylinder and so on).

Note that the argon gas is supplied from a gas cylinder only.

*1 Use of gas generators is recommended because of avoiding extra work such as replacing cylinders for daily

maintenance.

*2 Some nitrogen generator support a function which generates a dry air. The nitrogen generator that we recommend has

supported the function(see 2.9.1.1). When using customer's gas generator, confirm that the function of generating the

dry air is available.

* Precautions When Using APCI and DUIS

When using high-purity nitrogen gas (e.g. gas cylinder or liquid nitrogen) and acetonitrile for mobile phase, polymers

derived from carbon are sometimes formed on the needle tip and might cause sensitivity to become unstable. (This does

not necessarily happen when a nitrogen gas generator is used or methanol is used for the mobile phase.)

If this happens, polymer formation can be prevented by using a dry air (or a synthetic air) as the nebulizer gas.

(Reference)

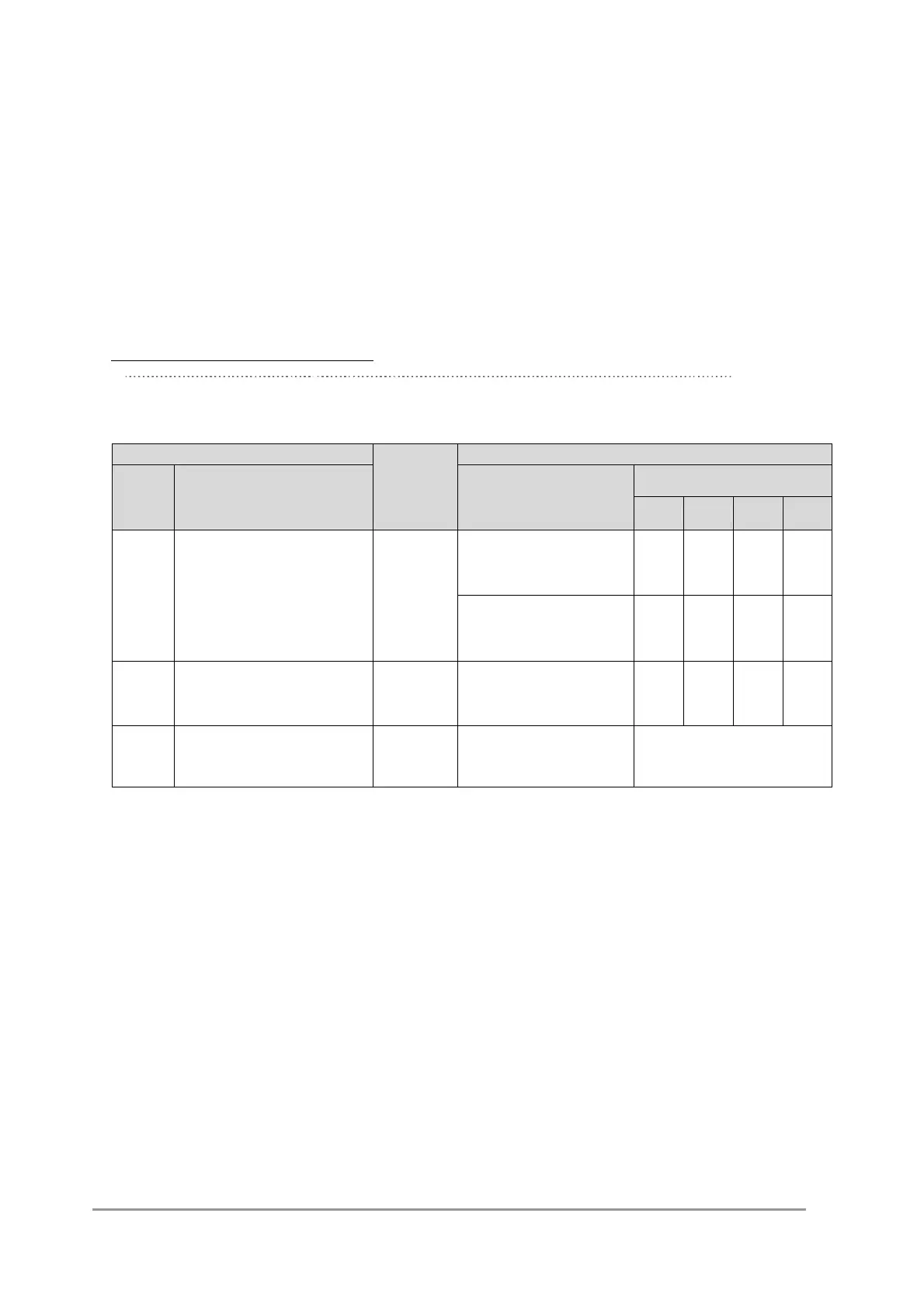

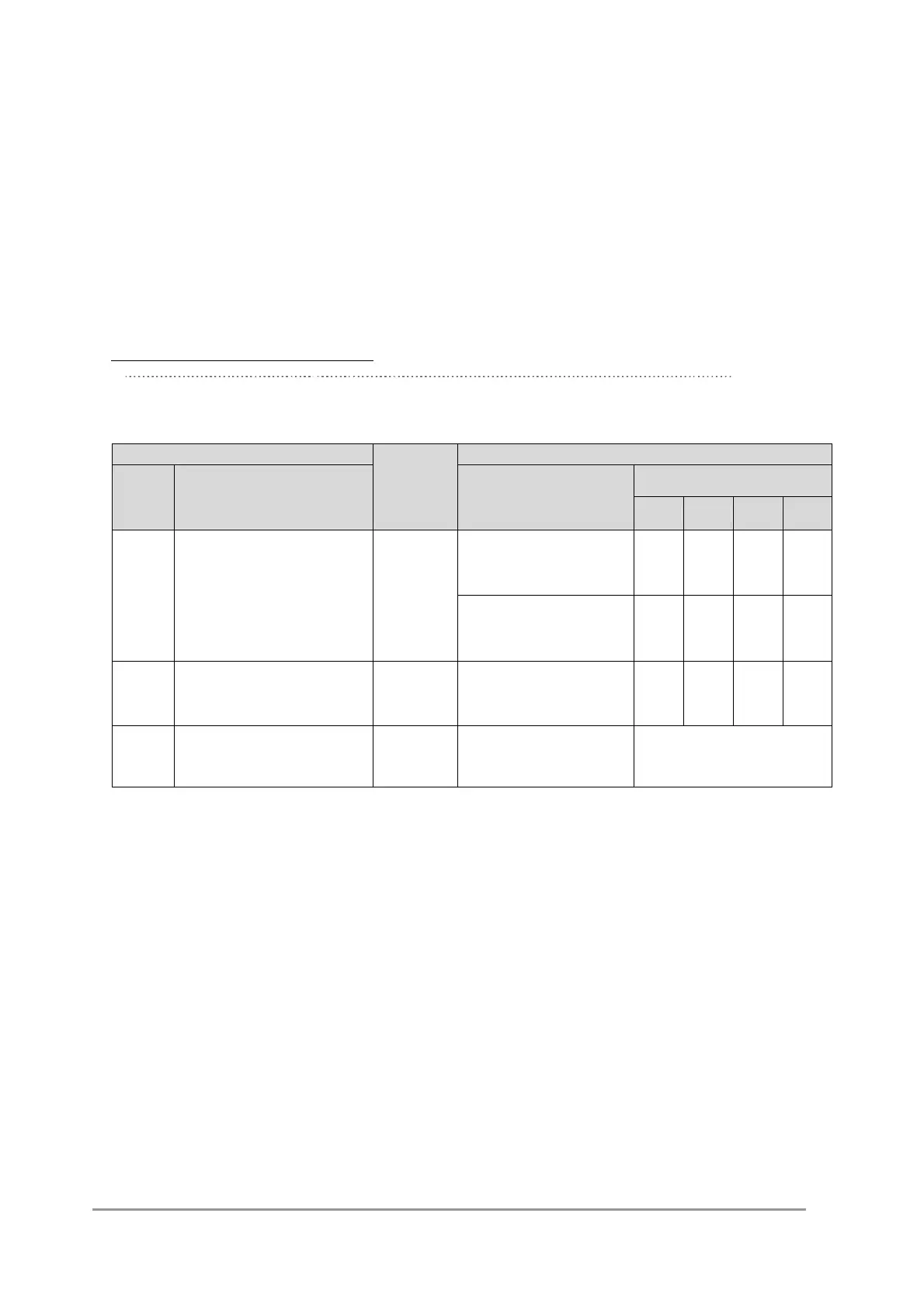

At normal use

In case of nitrogen gas generator

97.0 % or more

other than those above(gas

cylinder, liquid nitrogen,etc )

99.5 % or more

(*1)

Nebulizer gas (L/min)

(ESI/DUIS/MicroESI) 3.0

(APCI) 4.4

Drying gas (L/min)

20.0

(*5)

Water‐free,Oil-free

(In case of gas generator)

(*3)

Heating gas (L/min)

20.0

(*5)

LCMS-8045: 230 (kPa)

LCMS-8050: 270 (kPa)

See * 2.9.2

*1 Organic-free nitrogen gas

*2 Use of a hydrocarbon trap is recommended.

*3 When using a gas cylinder for synthetic air, 690〜800(kpa) is required for the supply pressure where an

atmospheric composition needs CO:less than 1ppm, CO2:less than 1ppm, HC:less than 1ppm,

H2O:-50℃(dew point).

*4 When supplying gas to other equipment as well, sufficient care must be paid to equipment used and

amounts of gas used since drops in the supply pressure can cause the flow rate to drop.

*5 The maximum flow reaches 20L/min in total as the default setting, whose value is disable and variable,

where the flow is the sum of the drying gas and the heating gas.

e.g. When setting 10L/min as the drying gas, the heating gas is available for 10L/min or less. Moreover

when turning off the drying gas, the heating gas is available for 20L/min or less.

Loading...

Loading...