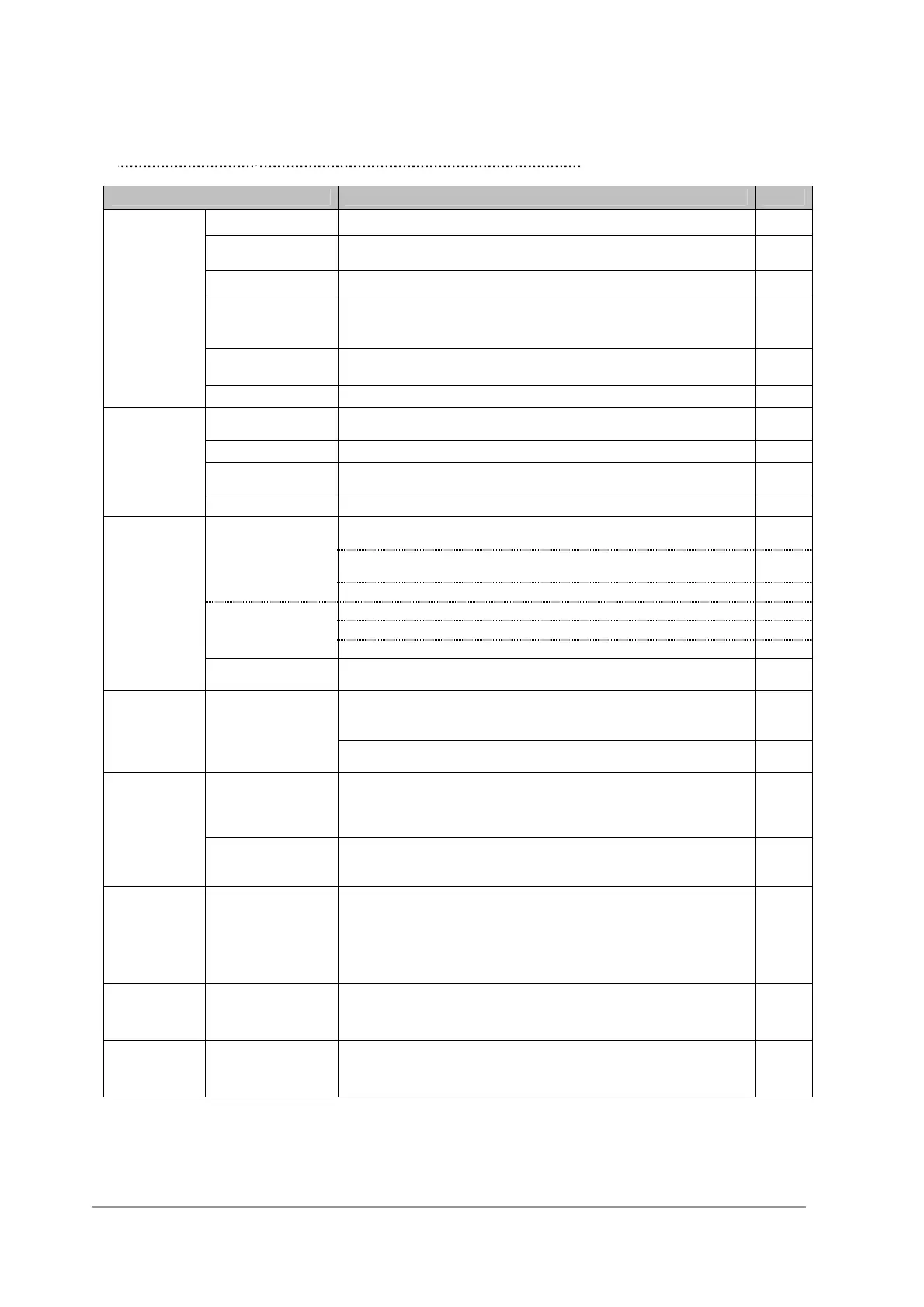

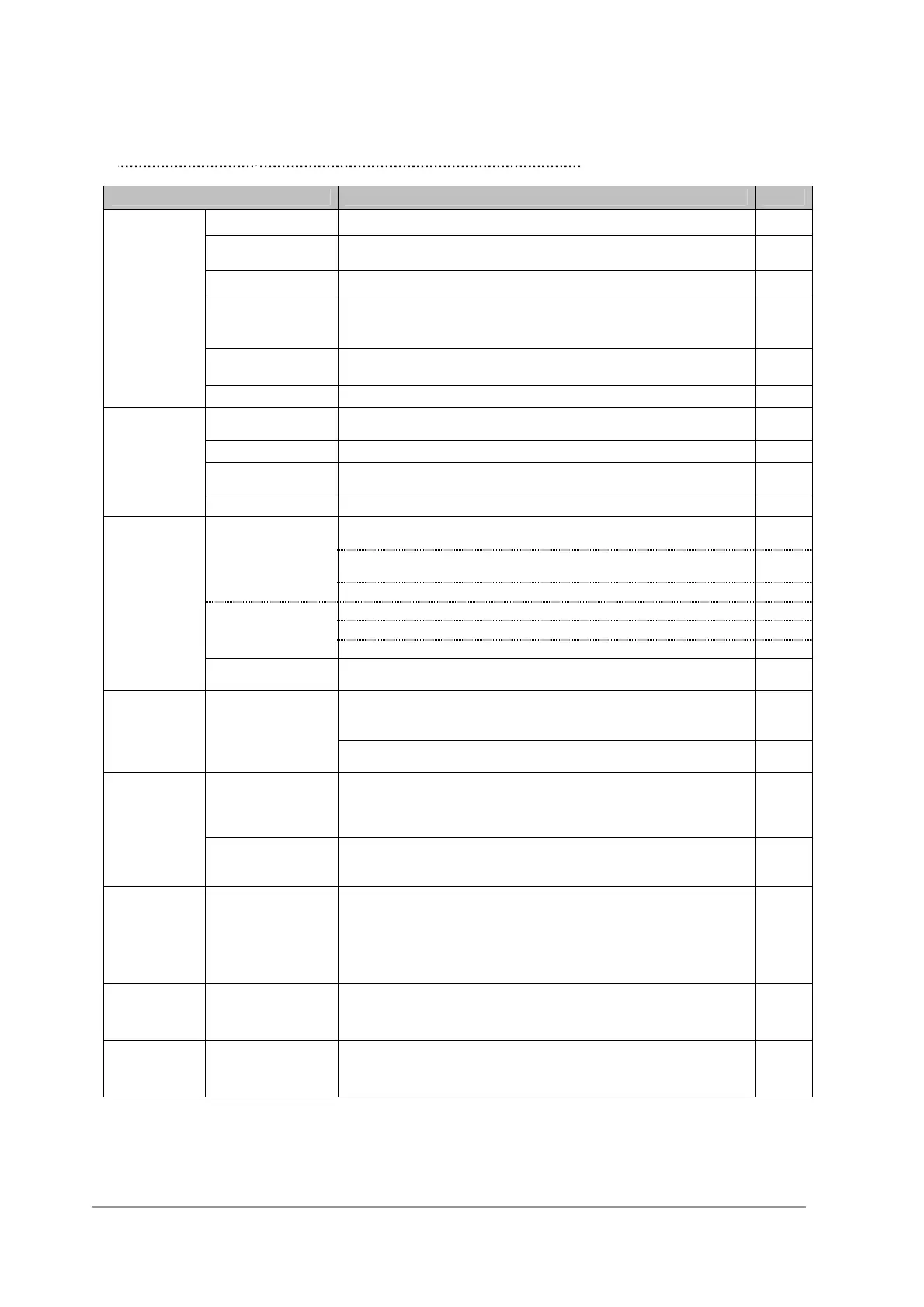

3 Preliminary Check List

LCMS-8045/8050

Pre-Installation Requirements

20

LCMS Check List

* For details of the LC system, refer to the LC Pre-Installation Requirements.

1.Installation

environment

20 to 70 %

No condensation and discharge caused by static electricity

See 2.7 System Installation Example.

LCMS weight: 140 kg (additional LC unit, PC and others)

The installation site should be of sufficient strength to withstand

this weight.

Space at back

(Rotary pump space)

At least 600 mm for rotary pump installation and maintenance

The space of the Nitrogen generator, Ar cylinder

230 V, (fluctuation ±5 %)

(The guarantee performance range 218.5 to 241.5)

LC system, N2/DryAir generator, PC, Printer

Nitrogen gas

*On the APCI/DUIS, dry air depending on conditions. See 2.9.

Gas purity

99.5% or more (97 % (when using a nitrogen gas generator))

Gas pressure 690 to 800 kPa

Dry air (Oil-free, Water-free)

Gas pressure 690 to 800 kPa

Hydrocarbon trap(recommended)

Argon gas

(Purity: 99.99 % or more, Pressure: 500 to 800 kPa)

Evacuation of the

solvent vapor from

the interface and

rotary pump

exhaust.

Evacuation facilities such as a draft chamber (example:

20 m3/min)

Evacuation tube length: 10 m (max.)

Mobile phase,

rinsing solution

▪ Water (ultrapure water)

▪ Acetonitrile LCMS grade

▪ Methanol LCMS grade (at installation of APCI)

▪ Isopropanol (for rinsing flow line)

▪ Standard Sample (for Tuning)

▪ Reserpine (for ESI/APC/Micro ESII)

▪ Acetophenone (for DUIS)

▪ Drain bottle

▪ Reservoir bottle

(mobile phase)

▪ (Maintenance

parts,

consumables)

Check with the Shimadzu representative as necessary.

Carry-in route and

equipment

An elevator must be available when installing the instrument on

the second or higher floor above the ground. Provide sufficient

check to the carry-in route.

8.Installing to

Existing

System

Explain the customer that the sensitivity check in case of the

installation to the existing system will be performed in the way of

just checking the obtained data without referring to the criteria.

Loading...

Loading...